Micro-channel evaporator and control method thereof

An evaporator and micro-channel technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problem of reduced heat transfer capacity of micro-channel evaporators, reduced heat transfer capacity of second-row heat exchangers, and impact on Rear row heat exchanger heat exchange and other issues, to achieve the effect of benefiting performance, reducing pressure drop, and strong frosting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

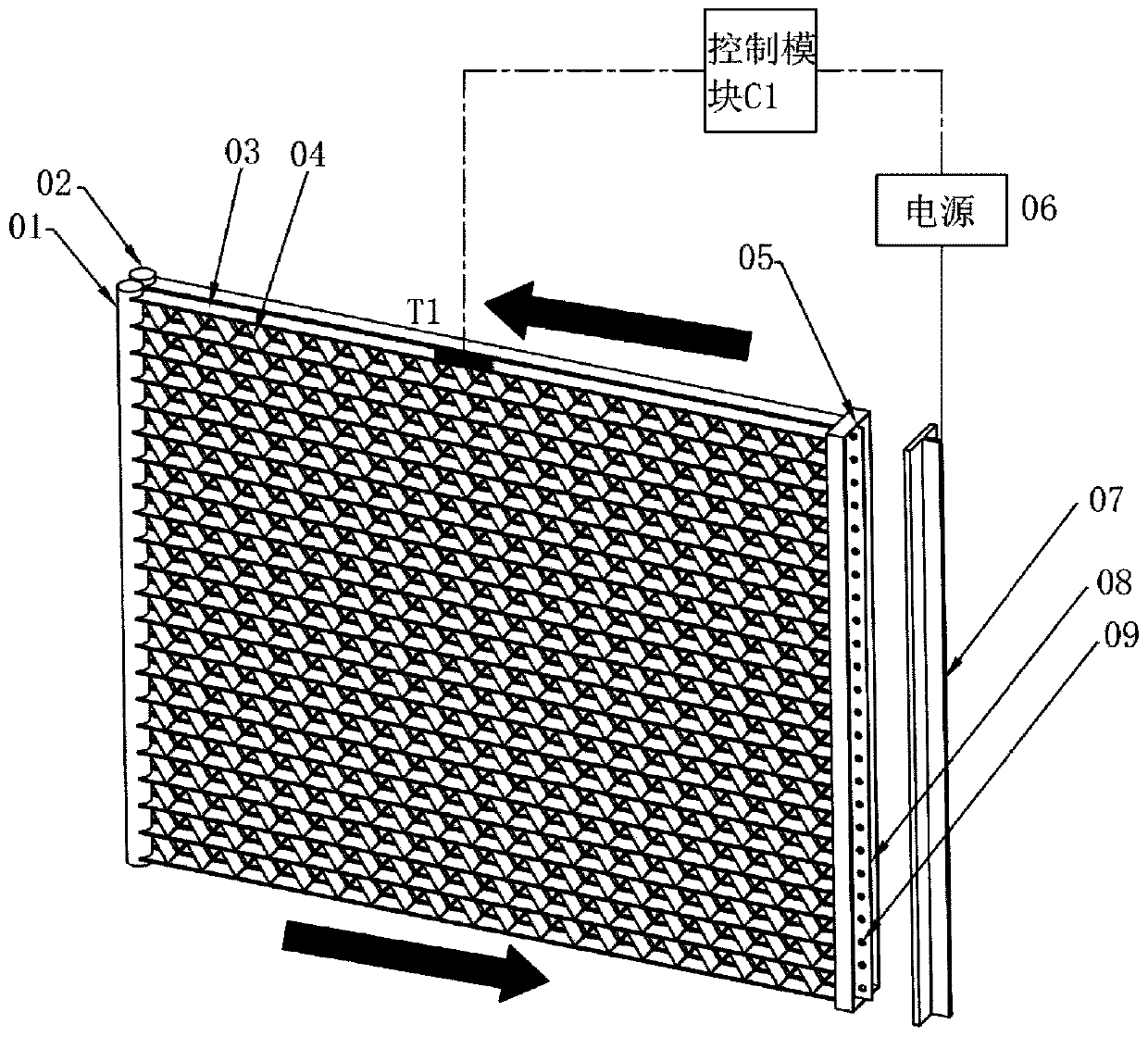

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

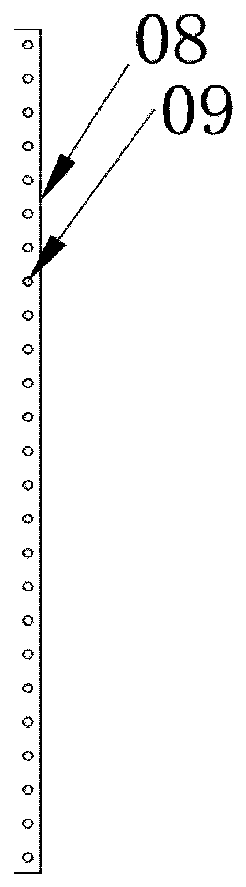

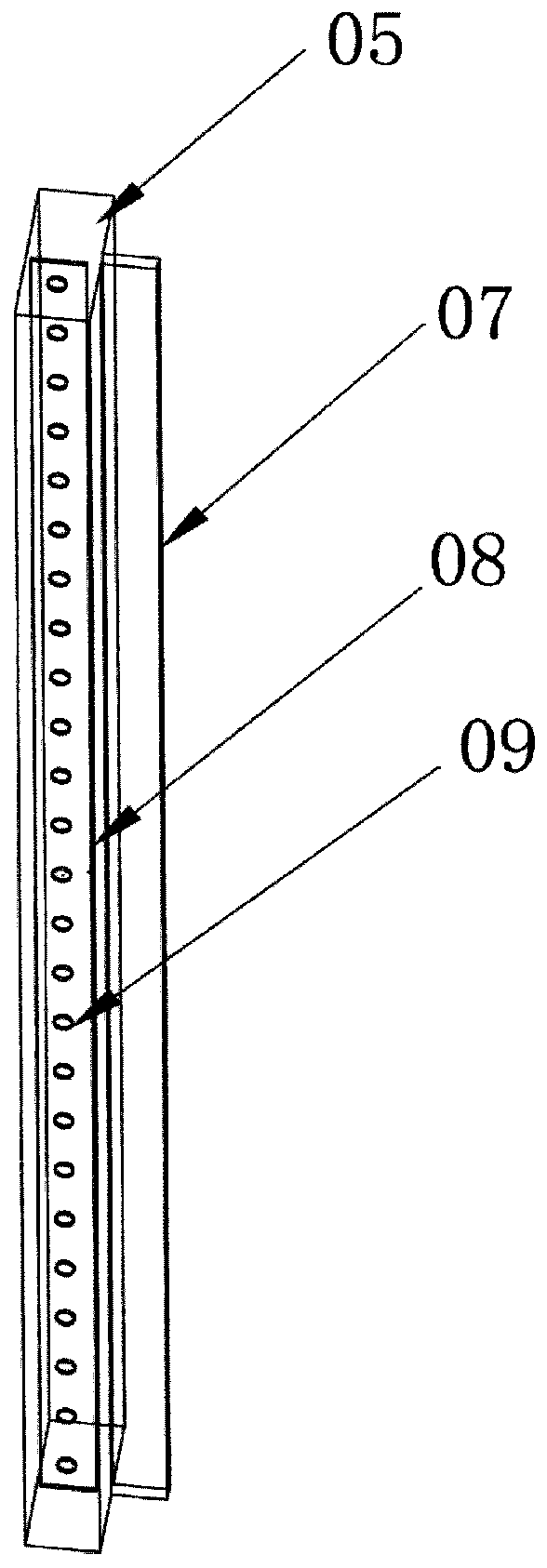

[0019] like figure 1 and figure 2 As shown, a microchannel evaporator of the present invention includes a first liquid collection pipe 01 and a second liquid collection pipe 02 arranged side by side, and a third liquid collection pipe on the opposite side of the first liquid collection pipe 01 and the second liquid collection pipe 02 The liquid collection pipe 05 is arranged between the first liquid collection pipe 01 and the third liquid collection pipe 05, the second liquid collection pipe 02 and the third liquid collection pipe 05 and communicates with the first liquid collection pipe 01 and the third liquid collection pipe 05. A plurality of flat tubes 03 of the second liquid collecting pipe 02 and the third liquid collecting pipe 05, the fins 04 installed between adjacent flat pipes, two rows of flat pipes 03 before and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com