A kind of textile yarn dyeing process

A technology for textile yarn and processing technology, which is applied in the field of textile yarn dyeing processing technology, and can solve the problems of yarns prone to dark and light color separation areas, mottled, and yarns that cannot be dried in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

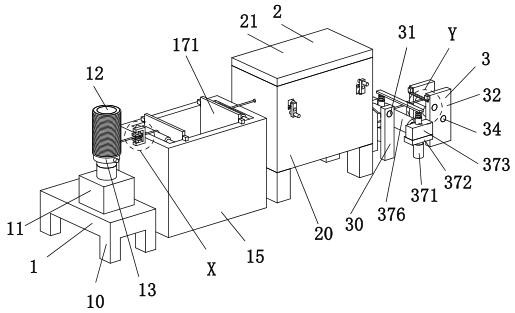

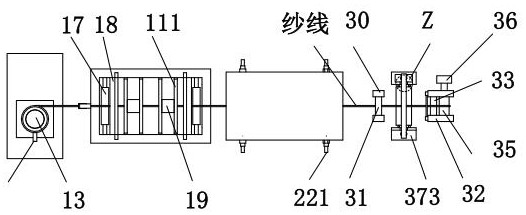

[0041] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

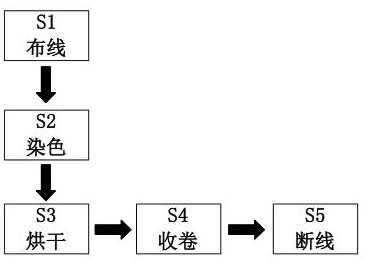

[0042] Such as Figure 1 to Figure 11 As shown, a textile yarn dyeing process, which uses a textile yarn dyeing device, the textile yarn dyeing device includes a dyeing mechanism 1, a drying mechanism 2 and a retracting mechanism 3, using the above textile yarn When the thread dyeing treatment device dyes the yarn, the specific treatment process is as follows:

[0043] S1. Wiring: Manually fit the original thread barrel 13 on the fixed shaft 12 and insert it into the bayonet pin 14 to fix it, and manually make a section of yarn on the original thread barrel 13 pass through the dyeing mechanism in sequence according to the S-shaped direction 1. Drying mechanism 2 and retracting mechanism 3;

[0044] S2. Dyeing: the No. 1 motor 11 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com