Antibacterial plant fiber reinforced composite material as well as preparation method and application thereof

A technology for reinforcing composite materials and plant fibers is applied in the field of antibacterial plant fiber reinforced composite materials and their preparation, and can solve the problems of poor antibacterial timeliness and no antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

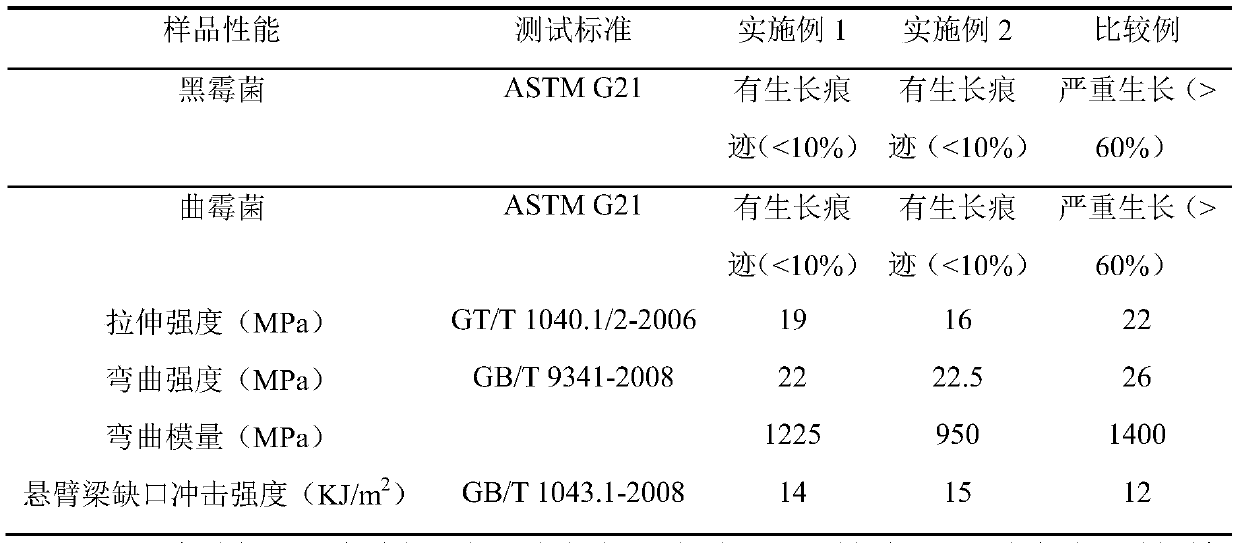

Examples

Embodiment 1

[0019] A preparation method of antibacterial plant fiber reinforced composite material, comprising the following steps:

[0020] Step 1: Soak the wheat straw in a 10% sodium hydroxide solution for 1 hour, then wash it with clean water and then freeze-dry it;

[0021] Step 2. Mix 10g of wheat straw soaked in alkaline solution, 1g of 3-mercaptopropyltrimethoxysilane and 1L of deionized water and adjust the pH value to 4, stir and react at 25°C for 1h to obtain surface mercaptolation Plant fiber modified materials;

[0022] Step 3: Add 2g of surface thiolated plant fiber modified material, 1g of methacryloyloxyethyltrimethylammonium chloride, and 0.1g of benzoin ethyl ether to 50ml of ethanol and pure water mixed solution with a volume ratio of 1:1 , adjust the pH value to 7.5, and react for 0.5h under the irradiation of ultraviolet light to produce thioene click reaction to obtain antibacterial plant fibers;

[0023] Step 4: blending 10 g of antibacterial plant fibers with 70 ...

Embodiment 2

[0025] A preparation method of antibacterial plant fiber reinforced composite material, comprising the following steps:

[0026] Step 1. Soak the corn stalks in a 5% sodium hydroxide solution for 24 hours, then wash them with clean water and freeze-dry them;

[0027] Step 2. Mix 20g of wheat straw soaked in alkaline solution, 5g of 3-mercaptopropyltrimethoxysilane and 100ml of deionized water and adjust the pH value to 7, stir and react at 25°C for 24h to obtain surface mercaptolation Plant fiber modified materials;

[0028] Step 3, adding 10g of surface mercaptolated plant fiber modified material, 5g of diene dimethyl ammonium chloride, and 0.5g of azobisisobutyronitrile into 100ml of ethanol and pure water mixed solution with a volume ratio of 1:1, Adjust the pH value to 11, and react for 1 hour under the irradiation of ultraviolet light to produce mercaptoene click reaction to obtain antibacterial plant fibers;

[0029] Step 4, blending 30 g of antibacterial plant fibers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com