Maleimide modified p-tert-butyl phenol formaldehyde resin and synthesis method thereof

A technology of maleimidophenol and p-tert-butylphenol is applied in the field of maleimide-modified p-tert-butylphenol formaldehyde resin and its synthesis, which can solve the problem of restricting the use of Koresin resin and having high technical requirements. , high cost and other problems, to achieve the effect of easier control of product structure, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

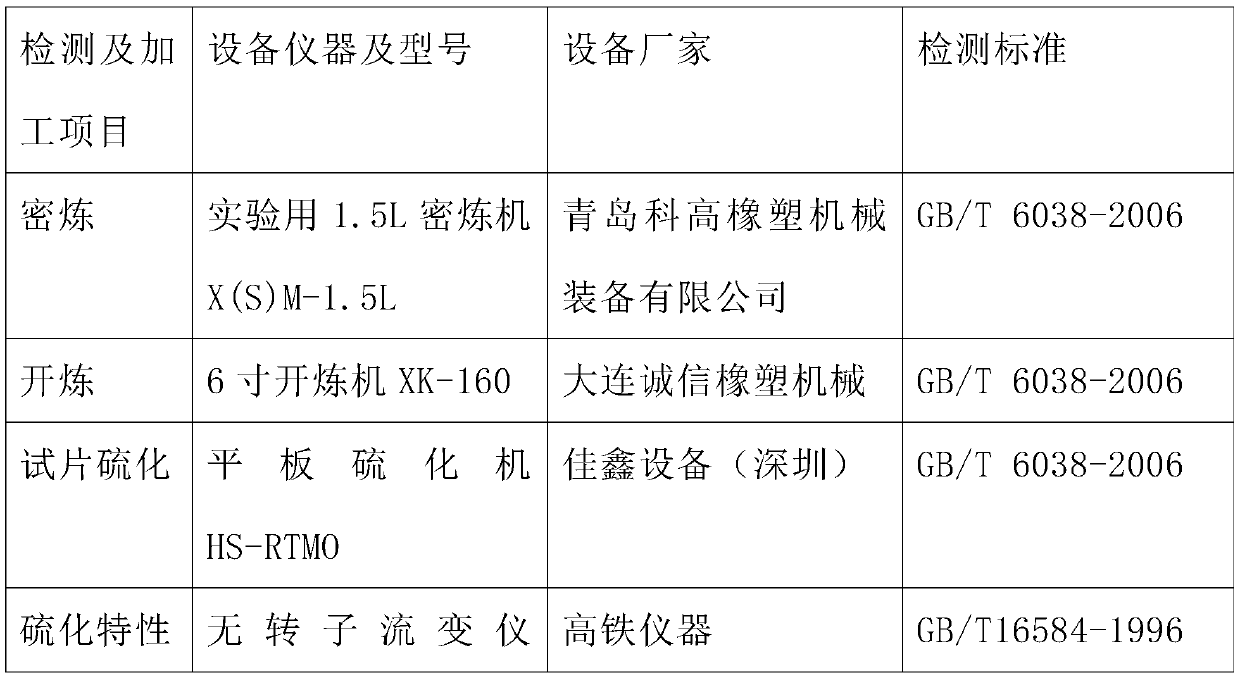

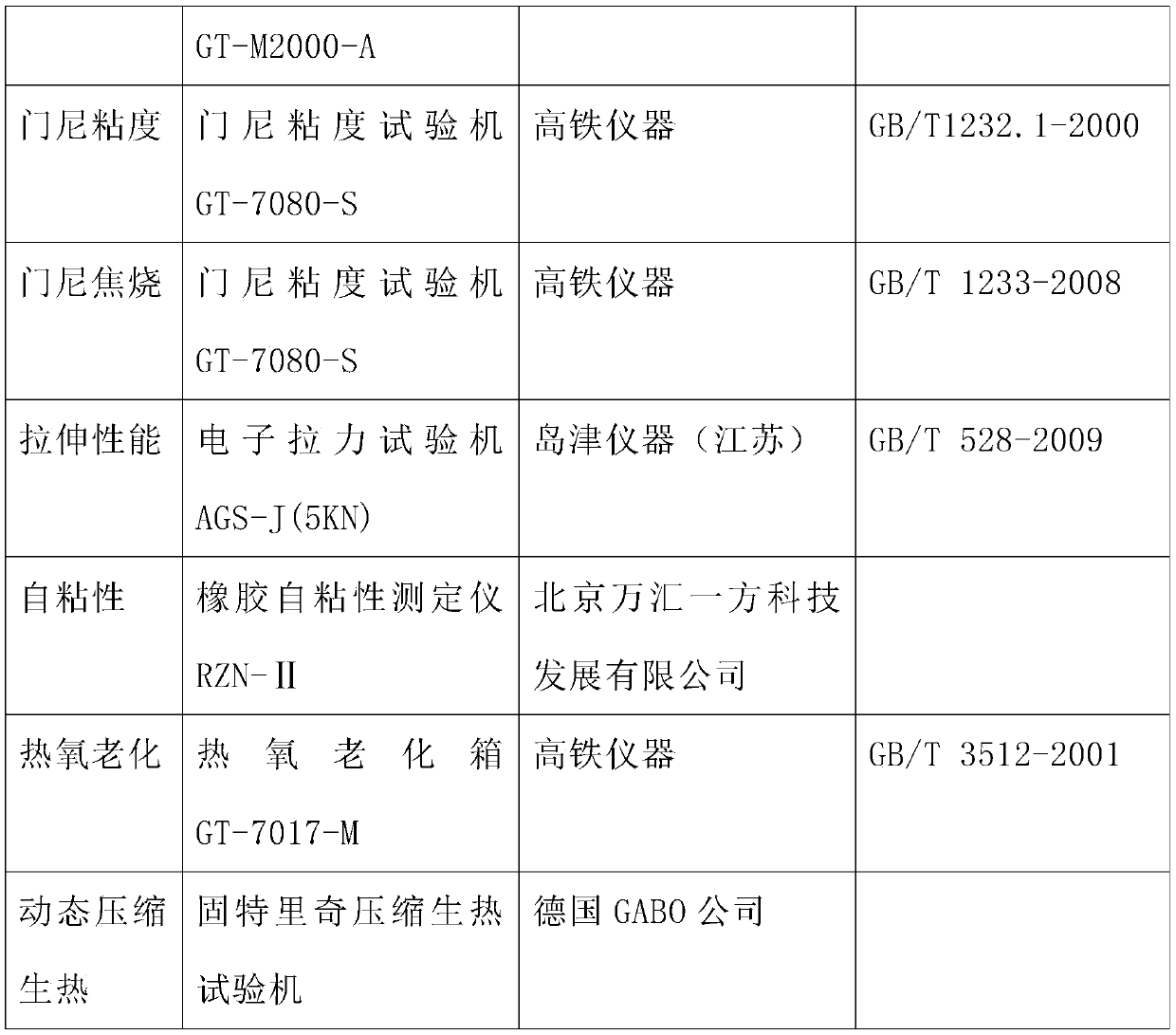

Image

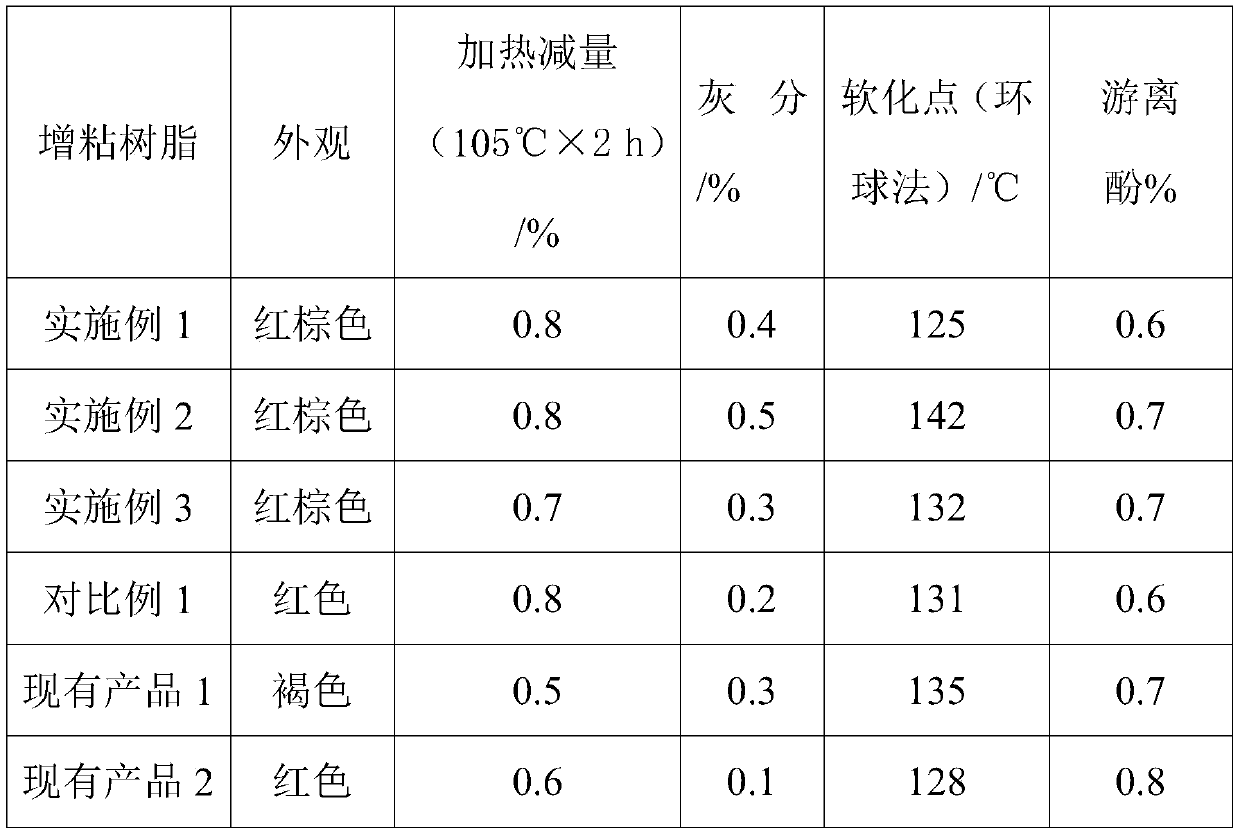

Examples

Embodiment 1

[0026] A kind of synthetic method of maleimide modified p-tert-butylphenol formaldehyde resin, comprises the steps:

[0027] Step 1: Weigh 100g (0.67mol) of p-tert-butylphenol, 1g of 4-maleimidophenol, and 0.3g of concentrated sulfuric acid, and add them to a 500ml solution equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel. In a four-neck round bottom flask, heat up to 90°C, add dropwise 44g of formaldehyde aqueous solution (phenol-formaldehyde ratio 1:0.8), and continue to react for 1 hour;

[0028] Step 2: After the reaction, add 150g of toluene, extract the organic phase, add lye to adjust the reaction solution to neutral. Drain the waste water, and slowly raise the temperature to 110°C to evaporate the water in the system. Subsequently, the temperature will be raised slowly, and water and toluene will be distilled off;

[0029] Step 3: heat up to 160°C for polycondensation, keep it for 1 hour, and distill under reduced pressure t...

Embodiment 2

[0032] A kind of synthetic method of maleimide modified p-tert-butylphenol formaldehyde resin, comprises the steps:

[0033] Step 1: Weigh 100g (0.67mol) of p-tert-butylphenol, 3g of 4-maleimidophenol, 0.2g of concentrated sulfuric acid, and add to a 500ml solution equipped with a mechanical stirrer, thermometer, reflux condenser and dropping funnel In a four-necked round bottom flask, the temperature was raised to 100°C, and 49 g of formaldehyde aqueous solution (phenol-formaldehyde ratio 1:0.9) was added dropwise, and the reaction continued for 3 hours.

[0034] Step 2: After the reaction, add 150g of toluene, extract the organic phase, add lye to adjust the reaction solution to neutral. Drain the waste water, and slowly raise the temperature to 110°C to evaporate the water in the system. Subsequently, the temperature will be raised slowly, water and toluene are distilled off,

[0035] Step 3: heat up to 190°C for polycondensation and keep for 2 hours; distill under reduce...

Embodiment 3

[0038] Step 1: Weigh 100g (0.67mol) of p-tert-butylphenol, 2g of 4-maleimidophenol, and 0.3g of p-toluenesulfonic acid, and add a mixture equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel In a 500ml four-neck round bottom flask, the temperature was raised to 95°C, and 44g of formaldehyde aqueous solution (phenol-formaldehyde ratio 1:0.8) was added dropwise, and the reaction continued for 2 hours.

[0039] Step 2: After the reaction, add 150g of toluene, extract the organic phase, add lye to adjust the reaction solution to neutral. Drain the waste water, and slowly raise the temperature to 110°C to evaporate the water in the system. Subsequently, the temperature will be raised slowly, water and toluene are distilled off,

[0040] Step 3: Carry out polycondensation at 180° C. for 3 hours; distill under reduced pressure to distill out small molecular substances and unreacted monomers. After discharging, the maleimide modified p-tert-but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com