Method for synthesizing penicillin G sulfoxide by using continuous flow reactor

A penicillin and reactor technology, applied in chemical instruments and methods, organic chemistry, chemistry/physics/physicochemical processes, etc., can solve the problems of dripping oxidant leakage, long reaction time, difficult control of reaction heat release, etc., and achieve improvement efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

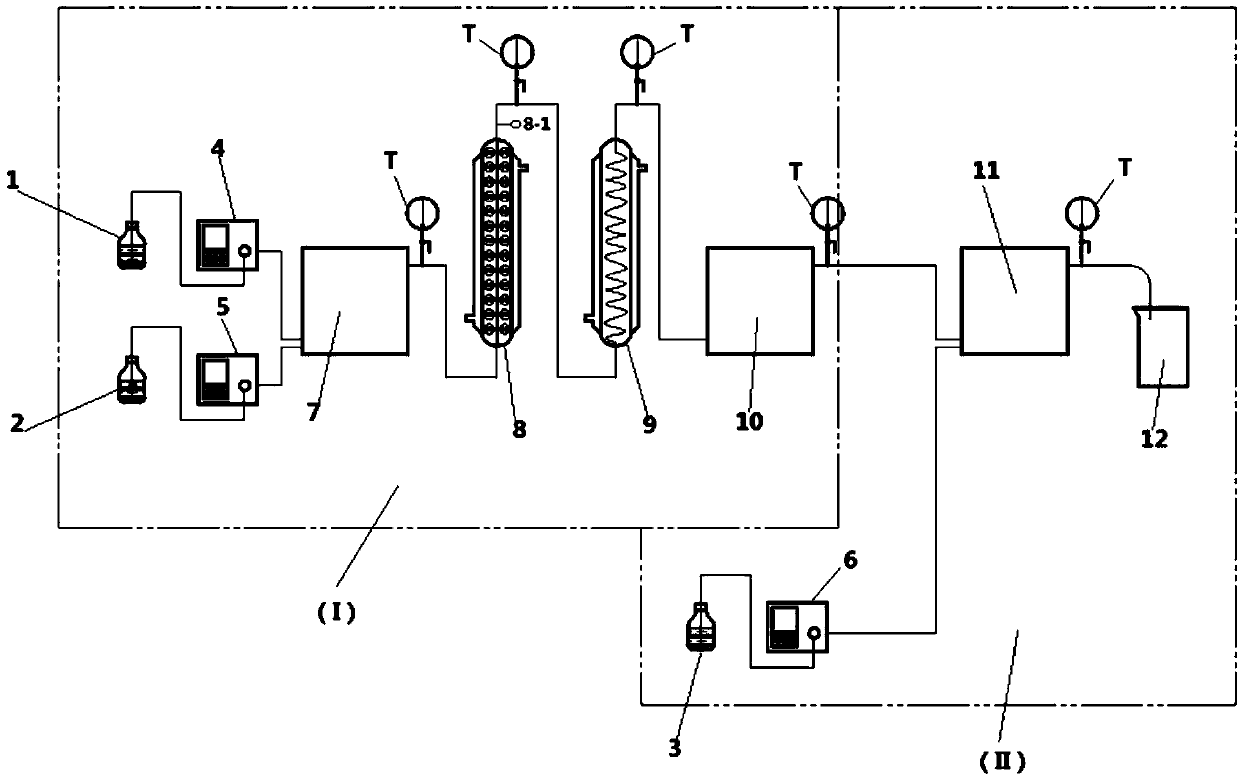

preparation example Construction

[0053] (1) Preparation of peracetic acid

[0054] Two constant flow pumps are used to inject hydrogen peroxide and glacial acetic acid into the premixing module at a certain flow rate, and the premixed peroxyacetic acid and glacial acetic acid react in the peroxidation reaction system, and the qualified product is obtained at the outlet. peracetic acid.

[0055] (2) Synthesis of Penicillin G Sulfoxide

[0056] Peracetic acid enters the pre-cooling plate after being connected to the cooling device to cool down. After flowing out from the pre-cooling plate, in the reaction module of the oxidation reaction system, the aqueous solution of penicillin G potassium salt with a certain flow rate pumped out from another constant flow pump is mixed and reacted in the oxidation reaction module. The material coming out from the oxidation reaction plate is penicillin G sulfoxide.

Embodiment 1

[0058] a, the preparation of peracetic acid

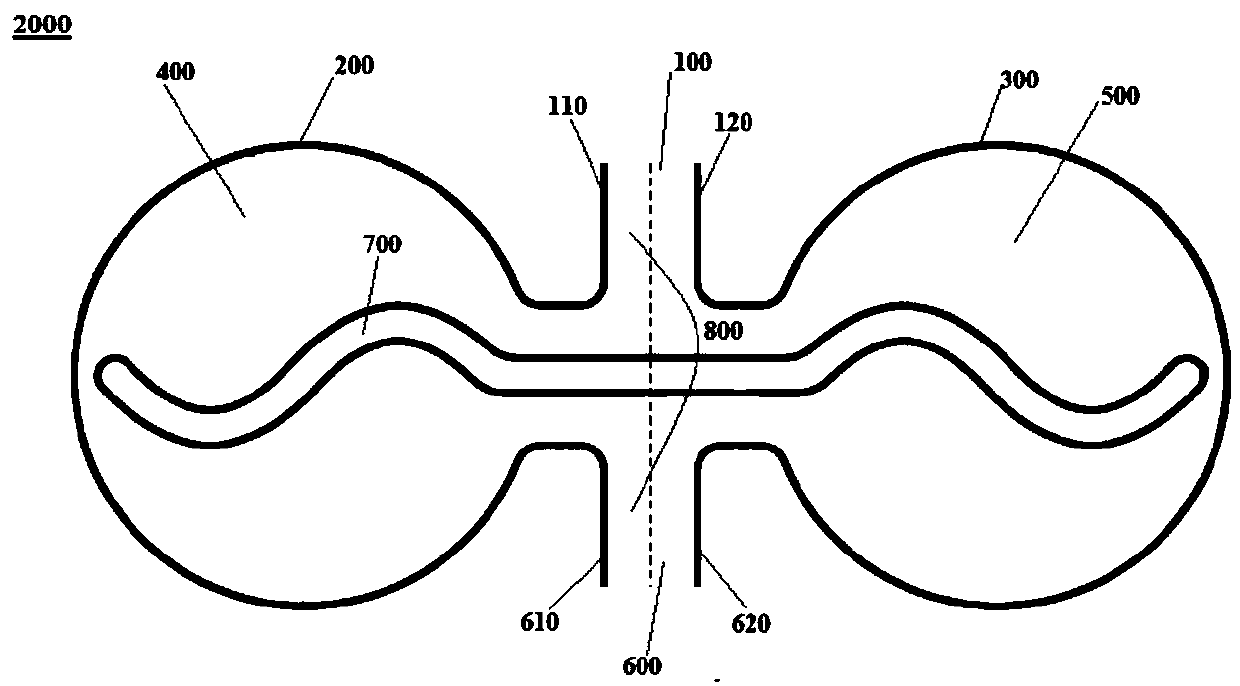

[0059] Add hydrogen peroxide (57mL) to the first holding bottle of 500mL, and pump it into the premixed module of the peroxidation reaction system at a flow rate of 3mL / min through the first constant flow pump; Add glacial acetic acid (190mL) into the bottle, pump it into the premixing module at a flow rate of 10mL / min through the second constant flow pump, and premix through three 7mL continuous flow plate premixing modules. The two materials enter the continuous flow tube reactor for reaction, and the continuous flow tube reactor is heated by the jacket to keep the temperature of the outlet at 35-48°C. The reactor adopts the same internal structure (i.e. attached figure 2 Composition of the unit shown), but the feed interface is 1, and the total volume is 50mL. Obtain about 235mL of peracetic acid at the outlet of the reactor, and take a sample to detect that the content of peracetic acid is 27.32%, and it is cooled to room tem...

Embodiment 2

[0063] a, the preparation of peracetic acid

[0064] Add hydrogen peroxide (57mL) to the first holding bottle of 500mL, and pump it into the premixed module of the peroxidation reaction system at a flow rate of 3mL / min through the first constant flow pump; Add glacial acetic acid (209mL) to the bottle, and pump it into the premix module at a flow rate of 11mL / min through the second constant flow pump. After two 7ml continuous flow plate premix modules are premixed, the two The material is put into the continuous flow tube reactor for reaction, and the continuous flow tube reactor is heated by the jacket to keep the outlet temperature at 48-55°C, wherein the reactor adopts the same internal structure as the continuous flow plate premixing module ( Attach figure 2 Composition of the unit shown), but the feed interface is 1, and the total volume is 50mL. About 250mL of peracetic acid was obtained at the outlet of the reactor, and the sampling test showed that the content of per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com