Method for preparing alkane by hydrogenating and photo-catalyzing fatty acid decarboxylation

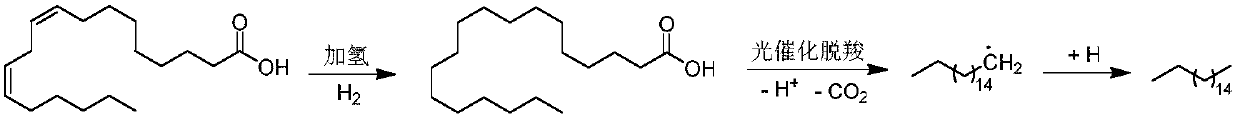

A technology of fatty acid and palm oil fatty acid, which is applied in the field of hydrogenation photocatalytic decarboxylation of fatty acid to prepare long-chain alkanes, can solve the problems of low conversion efficiency, limited substrate universality, harsh reaction conditions, etc., and achieve low hydrogen consumption and high yield High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

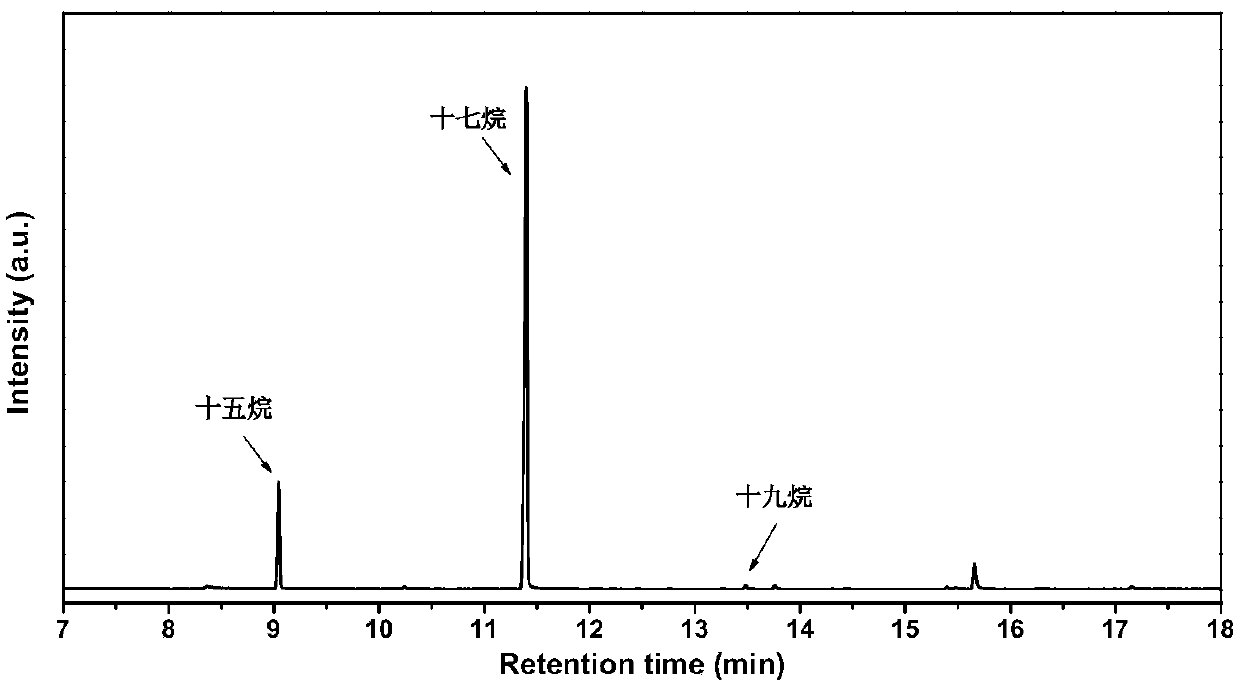

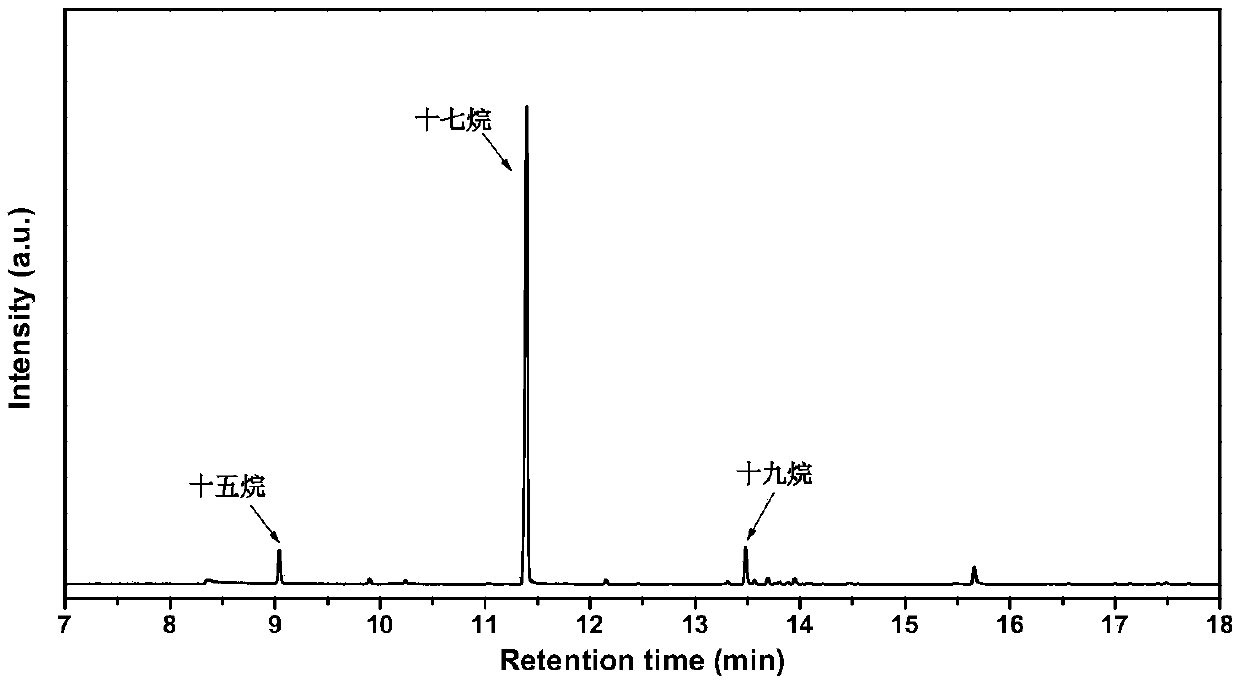

[0024] Add 1.5mL of linoleic acid acetonitrile solution (concentration is 10g / L) and Pt / TiO 2 (1wt%) 10mg, the atmosphere in the reaction tube was replaced with hydrogen (0.1MPa), sealed, stirred at 25°C for 1h, and then reacted for 2.0h under the irradiation of LED (center wavelength 365nm, 18W), the reaction temperature was 25°C, and the chromatographic Detection of product, product mass spectrum and standard spectrum Figure 1 As a result, the yield of heptadecane was 95%.

Embodiment 2

[0026] Add 1.5mL of linoleic acid acetonitrile solution (concentration is 10g / L) and Pd / TiO 2 (1wt%) 10mg, replace the atmosphere in the reaction tube with hydrogen (0.1MPa), seal it, stir at 25°C for 1h, then react for 2.0h under the irradiation of LED (center wavelength 365nm, 18W), the reaction temperature is 25°C, and the chromatogram Detection of product, product mass spectrum and standard spectrum Figure 1 As a result, the yield of heptadecane was 81%.

Embodiment 3

[0028] Add 1.5mL of linoleic acid in acetonitrile solution (concentration: 10g / L) and Ru / TiO 2 (1wt%) 10mg, replace the atmosphere in the reaction tube with hydrogen (0.1MPa), seal it, stir at 60°C for 1h, then react for 2.0h under the irradiation of LED (center wavelength 365nm, 18W), the reaction temperature is 25°C, and the chromatogram Detection of product, product mass spectrum and standard spectrum Figure 1 As a result, the yield of heptadecane was 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com