Preparation method of high-durability kiln furniture for positive electrode material of lithium power battery

A battery positive electrode and electric power technology, applied in the field of lithium batteries, can solve the problems of not meeting the requirements of alkaline corrosion resistance, high bearing pressure of kiln sticks, and increased corrosion of saggers, etc., to achieve strong bonding and corrosion resistance of the green body The effect of balancing performance and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

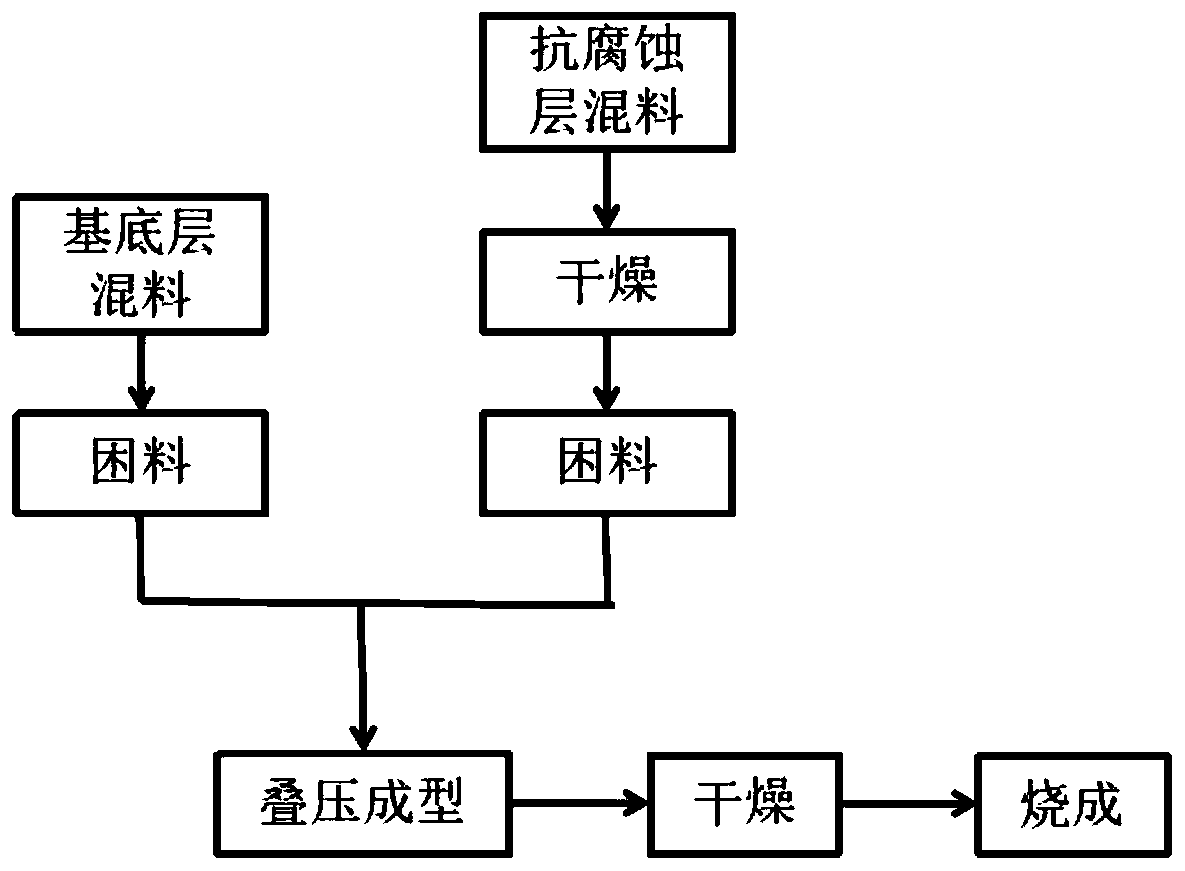

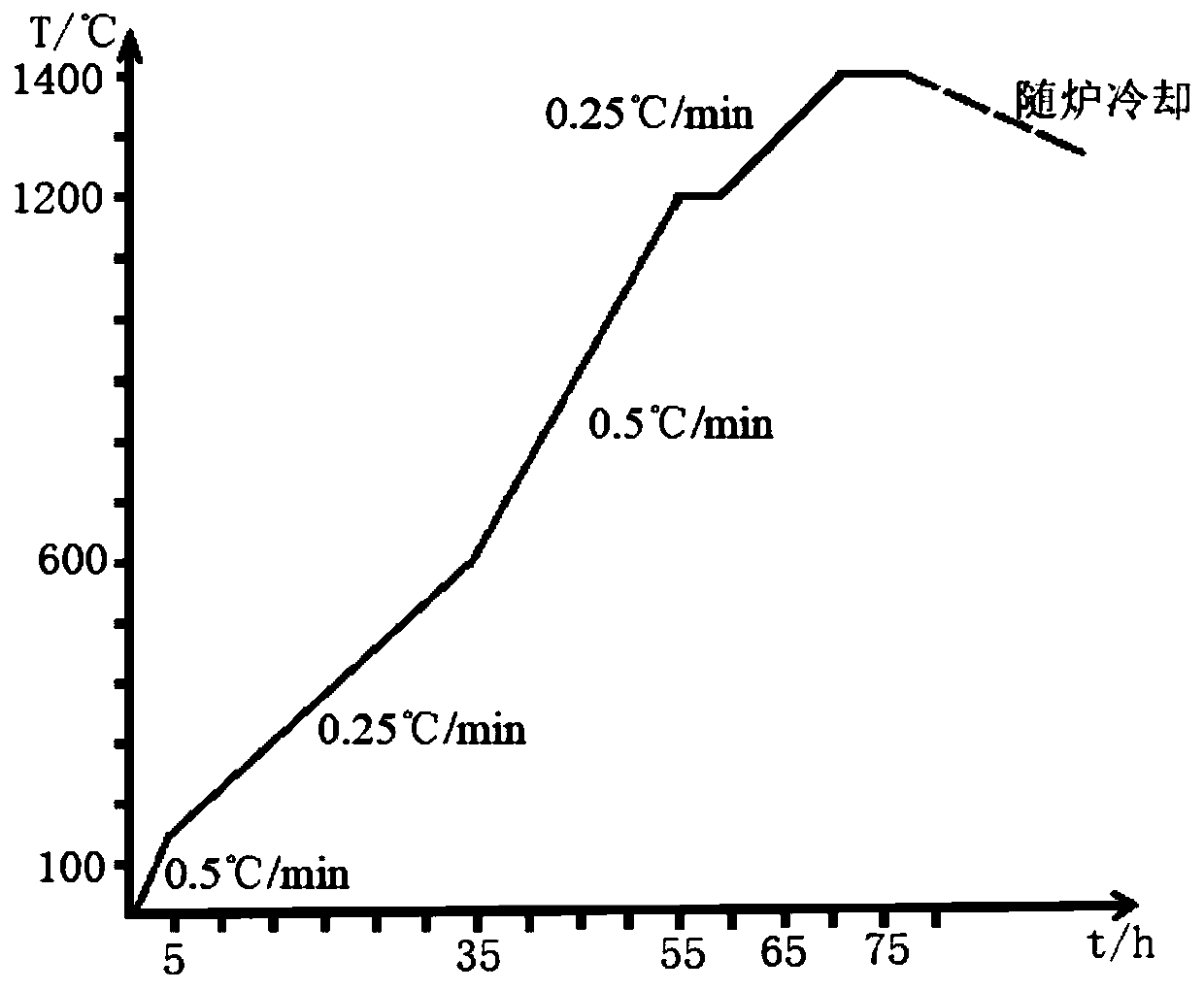

[0033] A method for preparing high-durability kiln furniture for positive electrode materials of lithium electric power batteries. The inner and outer layers of the kiln furniture are made of different materials; the base layer of the outer layer and the anti-corrosion layer of the inner layer are laminated and pressed, and then fired; Pressure treatment ensures strong bonding force, high yield and low cost; and the design of the inner and outer layers can not only use the outer layer to obtain good heat resistance, but also use the inner layer to obtain strong alkali resistance, reaching the weight of the kiln furniture. A balance of performance. The anti-corrosion layer is specifically arranged on the inner bottom of the base layer, with a thickness of 3-5mm; as attached figure 2 As shown, the hatched part represents the base layer part, and the black strip inside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com