A kind of coal gangue chemically foamed concrete and its preparation method

A technology of chemical foaming and coal gangue is applied in the field of building materials to achieve the effects of increasing specific surface area, good economic and social benefits, and improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

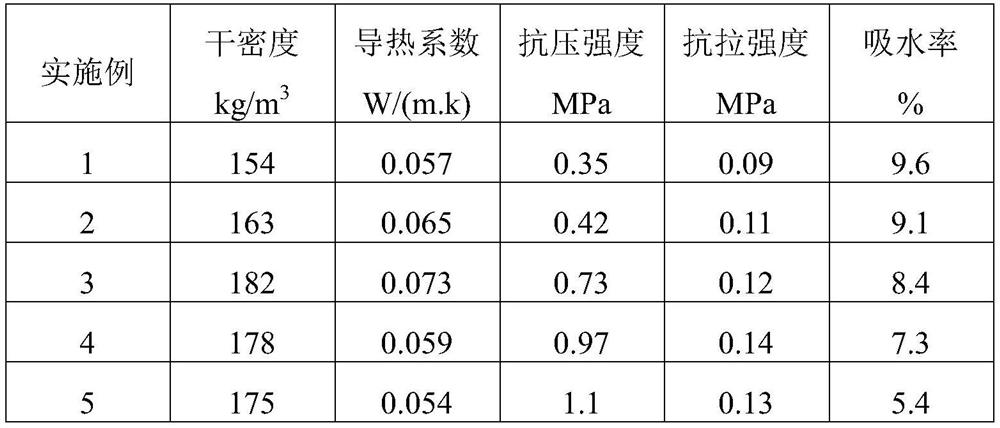

Examples

preparation example Construction

[0036] The preparation method of potassium chlorate solution used in the present invention is: 2kg potassium chlorate is dissolved in the 10kg water of 50 ℃, now mixes during use.

[0037] Both the foamed cement waterproof foam stabilizer and the foamed cement early strength enhancer used in the present invention were purchased from Langfang Shuiteng Chemical Co., Ltd.

Embodiment 1

[0039] A coal gangue chemically foamed concrete, including raw materials in the following mass ratio: rapid hardening sulfoaluminate cement 52.570: mixture of coal gangue (0.16mm in particle size) and quicklime 30: foamed cement waterproof foam stabilizer 2: foam Cement early strength enhancer 0.8: β-naphthalene sulfonate sodium formaldehyde condensate 0.5: manganese dioxide 0.8: water 45: potassium chlorate solution 12.

[0040] Wherein, the mass ratio of gangue and quicklime in the mixture of gangue and quicklime is 10:2.

[0041] The preparation method of the mixture of coal gangue and quicklime is:

[0042] ① Soak the gangue with water for 24 hours (the solid-to-liquid ratio of gangue and water is 5kg: 1L);

[0043] ② Add quicklime to the coal gangue soaked for 24 hours, ball mill for 1 hour, and pass through a sandstone standard sieve to obtain a mixture of coal gangue and quicklime with a particle size of 0.16mm.

[0044] The preparation method of coal gangue chemicall...

Embodiment 2

[0051] A coal gangue chemically foamed concrete, comprising the following raw materials in mass ratio: rapid hardening sulfoaluminate cement 52.570: mixture of coal gangue (0.315 mm in particle size) and quicklime 30: foaming cement waterproof foam stabilizer 2: foaming Cement early strength enhancer 0.8: β-naphthalene sulfonate sodium formaldehyde condensate 0.45: manganese dioxide 0.8: water 35: potassium chlorate solution 12.

[0052] Wherein, the mass ratio of gangue and quicklime in the mixture of gangue and quicklime is 10:2.

[0053] The preparation method of the mixture of coal gangue and quicklime is:

[0054] ① Soak the gangue with water for 24 hours (the solid-to-liquid ratio of gangue and water is 5kg: 1L);

[0055] ② Add quicklime to the coal gangue soaked for 24 hours, ball mill for 1 hour, and pass through a sandstone standard sieve to obtain a mixture of coal gangue and quicklime with a particle size of 0.315 mm.

[0056] The preparation method of coal gangue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com