Device for preparing super-capacitor activated carbon by alkali activation method and preparation method thereof

A technology of supercapacitor and activated carbon, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of equipment corrosion by activator, difficult to achieve continuous operation, long time consumption, etc., to ensure batch stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

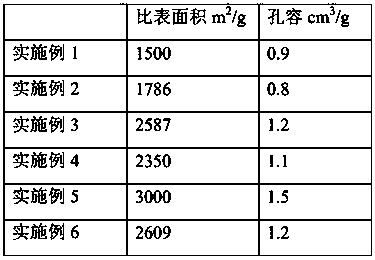

Embodiment 1

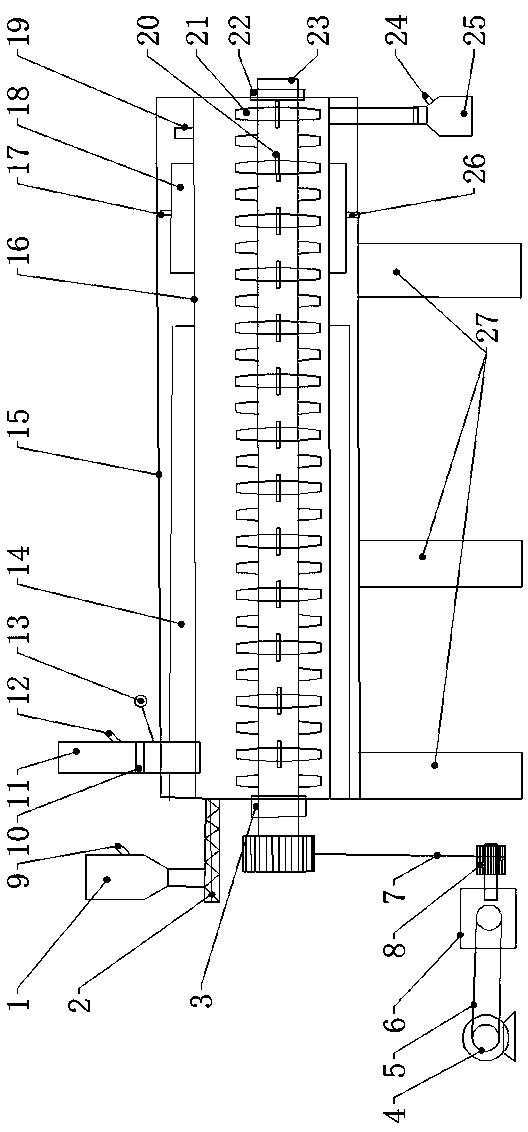

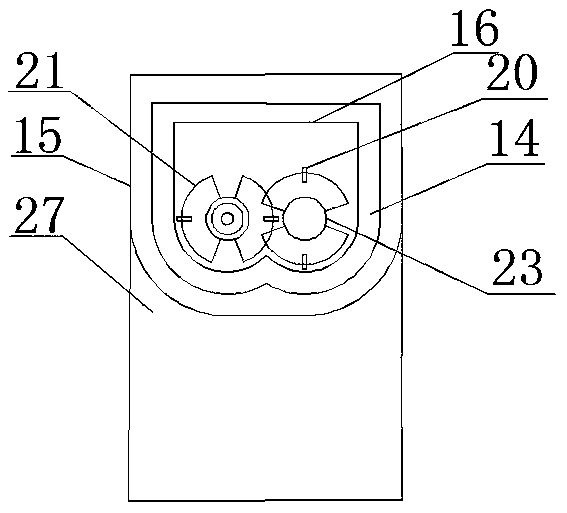

[0030] Such as figure 1 and figure 2 The shown device for preparing supercapacitor activated carbon by alkali activation method includes a furnace body, a feed unit and a drive unit, wherein:

[0031] The feeding unit includes a feeding bin 1 and a screw feeder 2, the side wall of the feeding bin 1 is provided with a first protective gas interface 9, the outlet of the feeding bin 1 is connected to the inlet of the screw feeder 2 The feed port is connected, and the discharge port of the screw feeder 2 is communicated with the head end of the body of heater 16; The head end is provided with an exhaust gas discharge pipe 11, a pressure gauge 13 is provided on the side of the exhaust gas discharge pipe 11 close to the furnace cover 15, and a CO 2 Air inlet 12, pressure gauge 13 and CO 2 A valve 10 is installed on the tail gas discharge pipe 11 between the air inlets 12, a heating zone is arranged at the head end of the furnace body 16 in the furnace cover 15, and a heating ele...

Embodiment 2

[0043] The device for preparing supercapacitor activated carbon provided by the alkali activation method in the second embodiment is the same as that described in the first embodiment, and will not be repeated here.

[0044] The preparation method of the device that is used for alkali activation method to prepare supercapacitor activated carbon, comprises the following steps:

[0045] S1. Mix the coconut shell carbonized material and potassium hydroxide according to the mass ratio of 1:2. The mixed raw material is pulverized in a pulverizer to 650 mesh, and then the mixed raw material is uniformly added to the feeding bin 1;

[0046] S2. Argon gas is fed through the protective gas ports 9, 19, and 24, and the opening of the valve 10 is adjusted to make the pressure gauge 13 a slight positive pressure. 2 Inlet 12 leads to CO 2 , access circulating water at the water inlet 26 and the water outlet 17 of the cooling water jacket 18;

[0047] S3, starting motor 11, motor 11 drive...

Embodiment 3

[0051] The device for preparing supercapacitor activated carbon provided by the alkali activation method in the third embodiment is the same as that described in the first embodiment, and will not be repeated here.

[0052] The preparation method of the device that is used for alkali activation method to prepare supercapacitor activated carbon, comprises the following steps:

[0053] S1. Mix petroleum coke, potassium hydroxide, sodium hydroxide and potassium carbonate according to the mass ratio of 1:1:1:1. The mixed raw materials are pulverized in a pulverizer to 325 mesh, and then the mixed raw materials are uniformly added to the feed bin 1. ;

[0054] S2. Nitrogen gas is fed through the protective gas ports 9, 19, and 24, and the opening of the valve 10 is adjusted to make the pressure gauge 13 a slight positive pressure. 2 Inlet 12 leads to CO 2 , access circulating water at the water inlet 26 and the water outlet 17 of the cooling water jacket 18;

[0055] S3, startin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com