Embroidery article and making method thereof

A production method and embroidery technology, which are applied in the field of embroidery products, can solve the problems of difficult thermal shearing, easy splitting of embroidery threads, and easy damage to embroidery threads in the embroidery part, and achieve the effects of preventing disordered positional relationship and improving bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in detail below with reference to the accompanying drawings showing embodiments of the present invention.

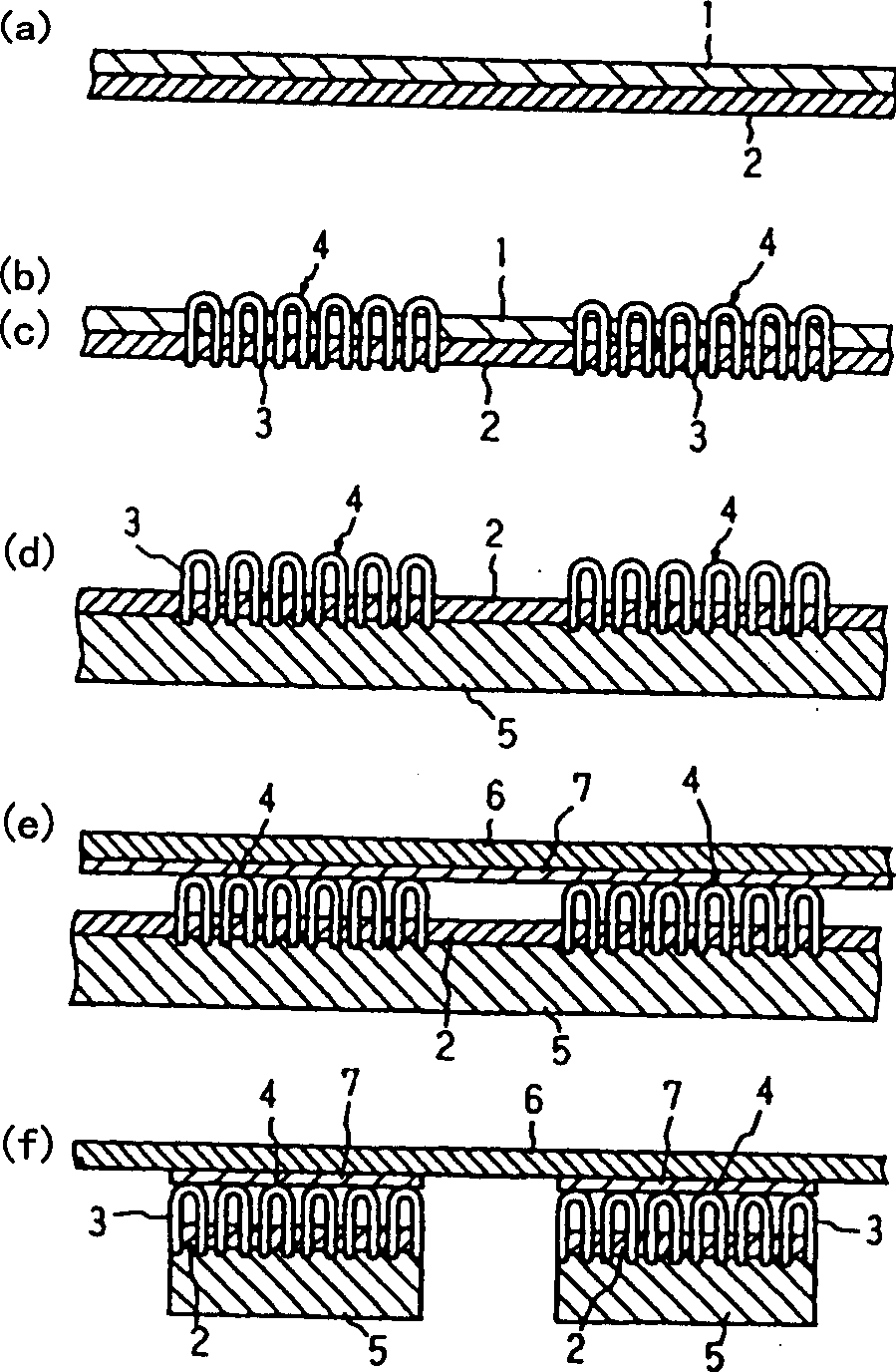

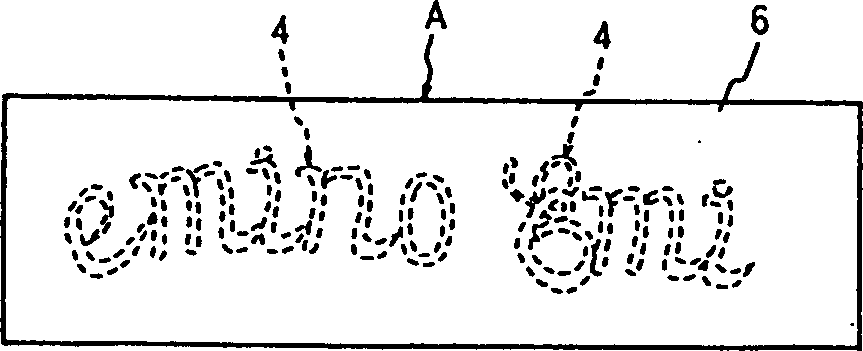

[0029] figure 1 It is a production process diagram of the embroidery product of the present invention.

[0030] figure 1 The production process of the illustrated embroidery product is as follows (a)-(f).

[0031] (a) A thermoplastic resin layer 2 composed of an insoluble and non-decomposable film such as polyamide, polyethylene, polystyrene, polypropylene, polyvinyl chloride, etc. is laminated on the texture 1, and the texture 1 is composed of It is composed of soluble substances such as acetate dissolved in acetone solution or silk dissolved in caustic soda solution, or decomposable substances such as water-soluble vinylon decomposed in water, warm water, etc.

[0032] (b) After the process of (a) is in a laminated state, the texture 1 and the thermoplastic resin layer...

Embodiment 2

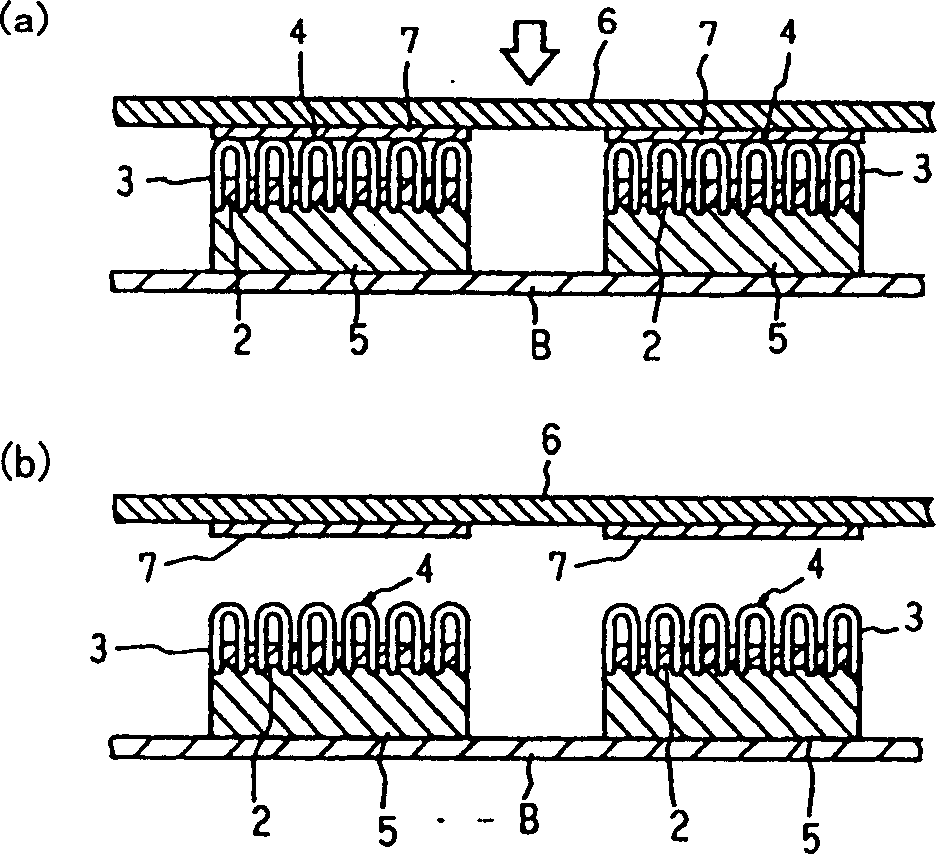

[0042] In this Example 2, in the step (C) of Example 1, the adhesive layer 5 made of the same thermoplastic resin as that of the thermoplastic resin layer 2 is used on the surface opposite to the texture (1) of the thermoplastic resin layer 2 . Lamination is carried out, and these laminates and the adhesive layer 5 are hot-pressed in the lamination direction to fix the rust wire 3 to the thermoplastic resin layer 2 . In addition, in the step (e) of Example 1, the sheet 6 is releasably bonded to the surface of the texture 1 side of the embroidered portion 4 formed by embroidering the thermoplastic resin layer 2 . Since the other production steps and configurations are the same as those in Embodiment 1, detailed descriptions and descriptions of operations thereof will be omitted.

[0043] In Example 2, since the adhesive layer 5 is formed in the process before dissolving or decomposing the texture 1, the adhesive layer 5 uses a film of an insoluble and non-decomposable thermopla...

Embodiment 3

[0045] In Example 3, the adhesive layer 5 of Examples 1 and 2 is bonded to the surface of the texture 1 side of the embroidery part 4 by hot pressing, and then on the surface opposite to the texture 1 side of the thermoplastic resin layer 2. The foil 6 is glued on the face. Since the other manufacturing steps and configurations are the same as those in Embodiment 1, detailed descriptions and descriptions of operations thereof will be omitted.

[0046] In Example 3, after the step (d) of Example 1, an adhesive layer 5 such as polyurethane or polyamide is bonded to the surface of the texture 1 side of the embroidery part 4 by hot pressing.

[0047] In the embroidery product A produced by the production method of Example 3, after the part embroidered with the thermoplastic resin layer 2 of the embroidery part 4 embroidered with the embroidery thread 3 is combined with the thermoplastic resin layer 2, the adhesive layer 5 Adhesive to the surface of the embroidery part 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com