Multistage reaction center oxidation catalyst as well as preparation method and application thereof

An oxidation catalyst and multi-stage reaction technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve the effect of improving degradation rate and degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

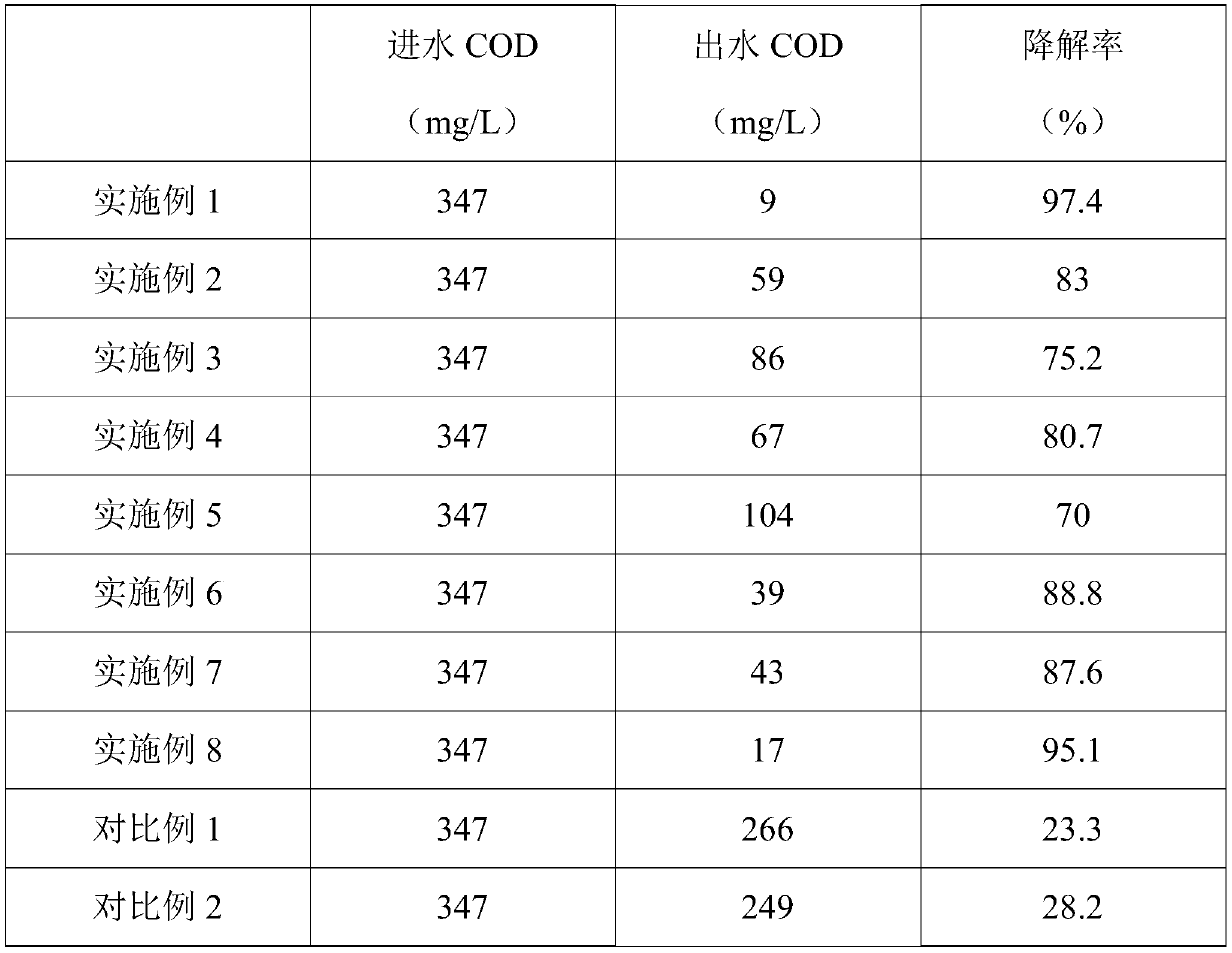

Examples

Embodiment 1

[0104] This embodiment provides a multi-stage reaction center oxidation catalyst, the catalyst includes an activated carbon matrix, and metal eutectic lattice-doped silica particles adsorbed in the pores of the activated carbon matrix, the metals include copper, nickel and Magnesium, metal co-lattice doped silica particles have a particle size of 3.5 nm and the activated carbon matrix has a pore size of 5.2 nm.

[0105] The preparation method of the multistage reaction center oxidation catalyst provided in this embodiment comprises the following steps:

[0106] (1) Stir and mix 10mL tetraethyl orthosilicate, 7mL ethanol and 70mL ethylene carbonate at 40°C and 120r / min for 70min to obtain solution A;

[0107] Put 5g of dodecyl pyridinium bromide in 80mL of distilled water, stir and dissolve for the first time at 25°C, 90r / min, then add 1.5g of hydroxymethyl urea, and carry out the second stirring at 25°C, 89r / min Secondary stirring and dissolving to obtain solution B;

[0108...

Embodiment 2

[0113] This embodiment provides a multi-stage reaction center oxidation catalyst, the catalyst includes an activated carbon matrix, and metal eutectic lattice-doped silica particles adsorbed in the pores of the activated carbon matrix, the metals include copper, nickel and Magnesium, metal co-lattice doped silica particles have a particle size of 4.6 nm and the activated carbon matrix has a pore size of 6 nm.

[0114] The preparation method of the multistage reaction center oxidation catalyst provided in this embodiment comprises the following steps:

[0115] (1) Stir and mix 20mL tetraethyl orthosilicate, 4mL ethanol and 60mL ethylene carbonate at 30°C and 60r / min for 120min to obtain solution A;

[0116] Put 8g of dodecyl pyridinium bromide in 100mL of distilled water, stir and dissolve for the first time at 20°C, 80r / min, then add 0.7g of hydroxymethyl urea, and carry out the second stirring at 20°C, 80r / min Secondary stirring and dissolving to obtain solution B;

[0117]...

Embodiment 3

[0122] This embodiment provides a multi-stage reaction center oxidation catalyst, the catalyst includes an activated carbon matrix, and metal eutectic lattice-doped silica particles adsorbed in the voids of the activated carbon matrix, the metals include copper, nickel, Magnesium and manganese, metal co-lattice doped silica particles with a particle size of 2.2 nm and activated carbon matrix with a pore size of 4 nm.

[0123] The preparation method of the multistage reaction center oxidation catalyst provided in this embodiment comprises the following steps:

[0124] (1) Stir and mix 8mL tetraethyl orthosilicate, 10mL ethanol and 80mL ethylene carbonate at 50°C and 180r / min for 30min to obtain solution A;

[0125] Put 3g of dodecyl pyridinium bromide in 75mL of distilled water, stir and dissolve for the first time at 30°C, 110r / min, then add 2.6g of hydroxymethyl urea, and carry out the second stirring at 30°C, 110r / min Secondary stirring and dissolving to obtain solution B; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com