An automatic device for efficiently producing safe and easy-to-tear masks and its production method

A technology of automation devices and production methods, applied in the field of machinery, can solve the problems of waste of labor resources, large labor consumption, and many production links, and achieve the effects of improving product quality and image, improving hygiene and safety, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

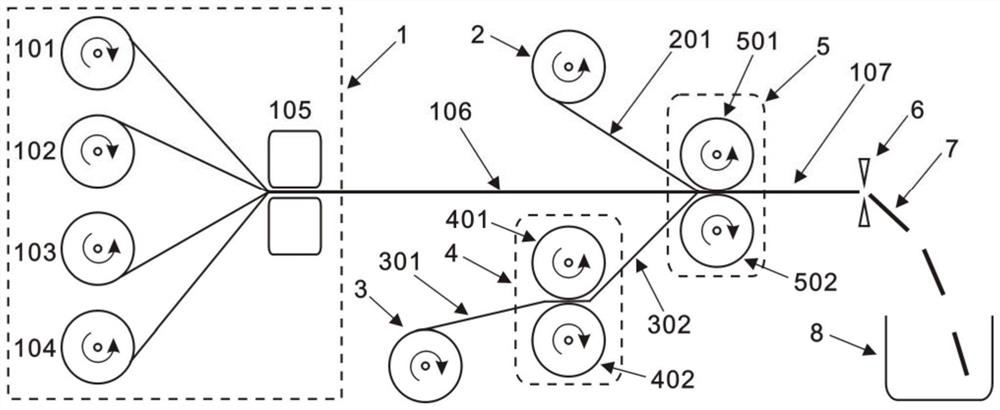

[0030] like figure 1 As shown, an automatic device for efficiently producing safe and easy-to-tear masks includes a mask body composed of a skin-friendly fabric 101, an intermediate filter layer 102, a bridge strip 103, a feeding device for a non-woven fabric 104, and a laminated flattening mechanism 105 Production unit 1 ( figure 1 Shown in the middle dotted line frame), this unit is no different from the prior art, and its effect is to complete the production and processing of the mask body 106.

[0031] In the traditional technology, the belt-shaped mask body 106 is cut off here to form independent mask pieces one by one. The difference of the present invention is that the belt-shaped mask body 106 is not cut off, but continues to use the belt-shaped structure to enter the synthesis process. Laminating stage.

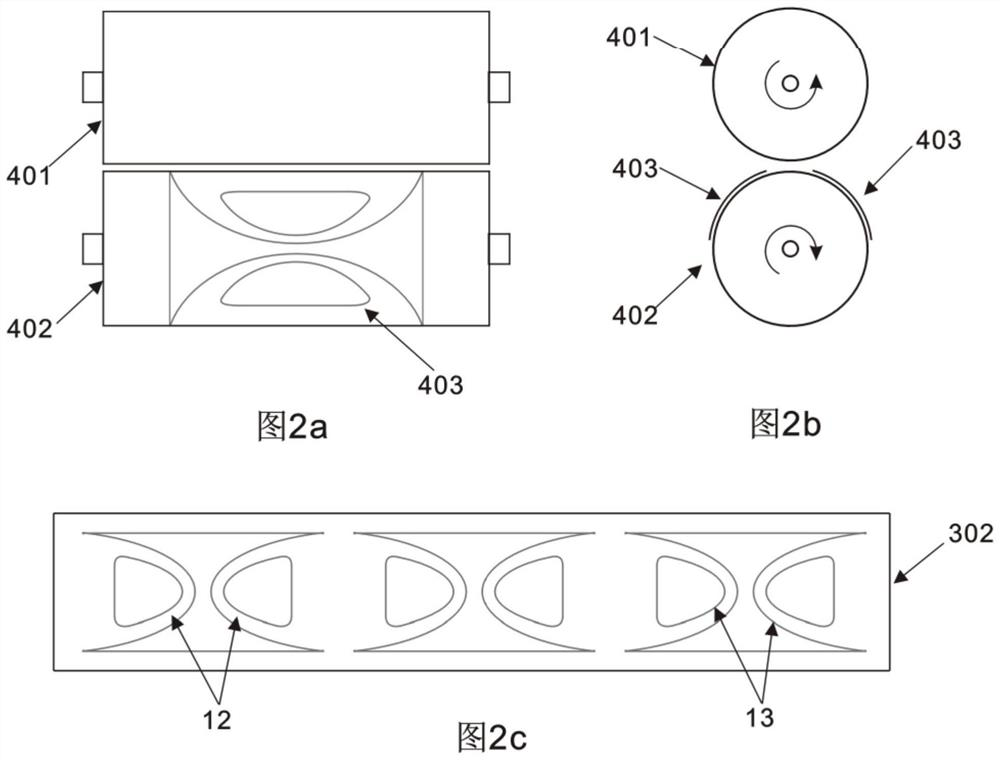

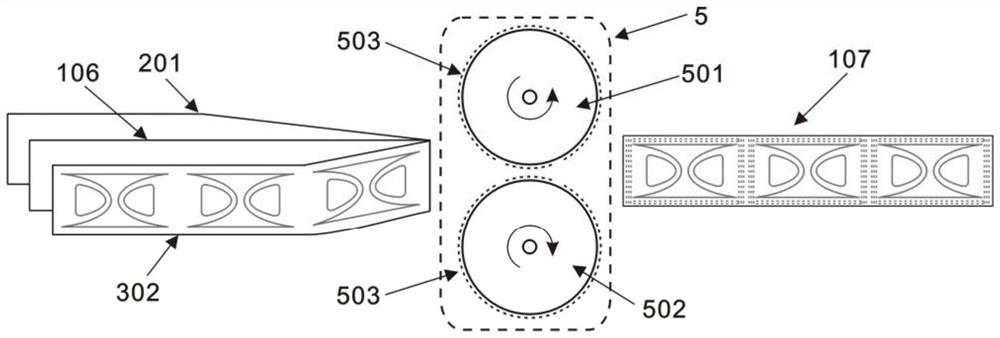

[0032] The comprehensive coating inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com