a dough mixer

A dough mixer and frame technology, which is applied in the field of dough mixers for outdoor processing of pasta, can solve the problems of small single processing volume, increased dough operations, unhygienic, etc., to improve hygiene and safety, increase use functions, and prevent The effect of falling dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

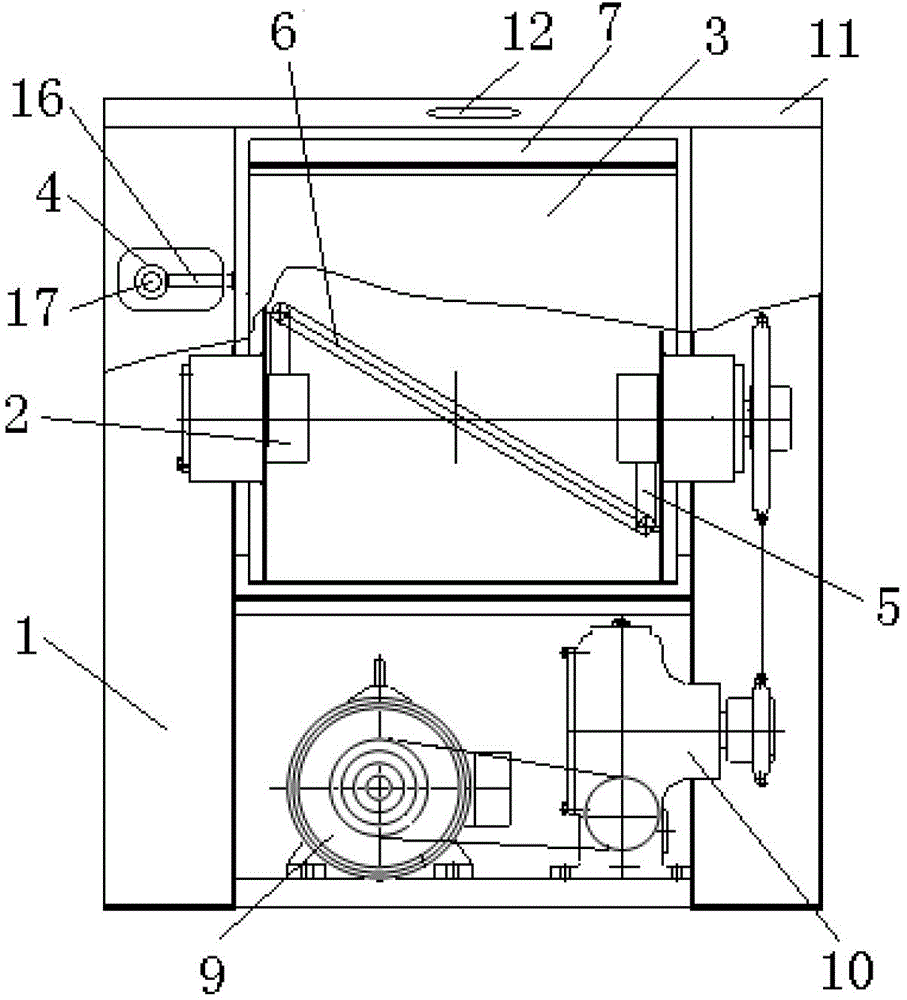

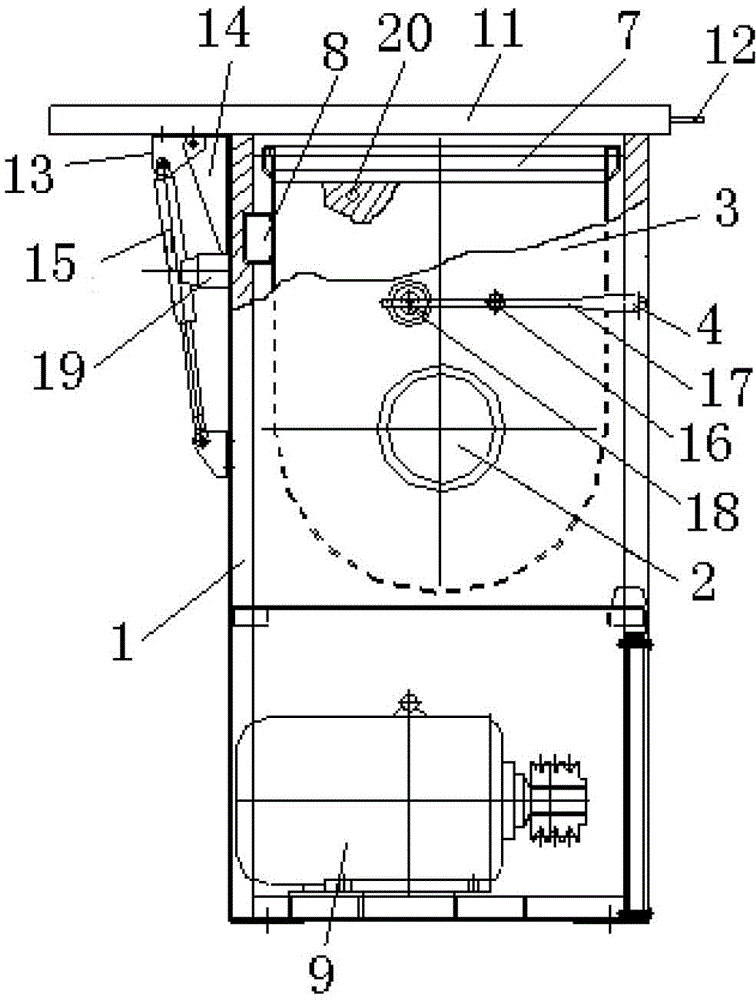

[0016] Such as figure 1 , figure 2 As shown, the present invention comprises a frame 1, and the middle part of the frame 1 is symmetrically provided with two rotating shafts 2, and the two rotating shafts 2 are jointly connected to a cylinder 3 by two bearings, and a lock is arranged between one side of the cylinder 3 and the frame 1. Tightening device 4. Two rotating shafts 2 in the surface cylinder 3 are respectively fixedly connected with a radially provided extension rod 5, and the extension directions of the two extension rods 5 are opposite, and the ends of the two extension rods 5 are respectively connected to one end of an auger 6. . The face cylinder mouth place of surface cylinder 3 is provided with a cylinder cover 7, and the both sides of surface cylinder cover 7 rear ends are hinged on the frame 1 shell. The rear of the frame 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com