A serrated electrode and a method for improving the performance of nano-ultraviolet detectors

A UV detector, sawtooth technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of incompatibility between the performance of metal electrodes and process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

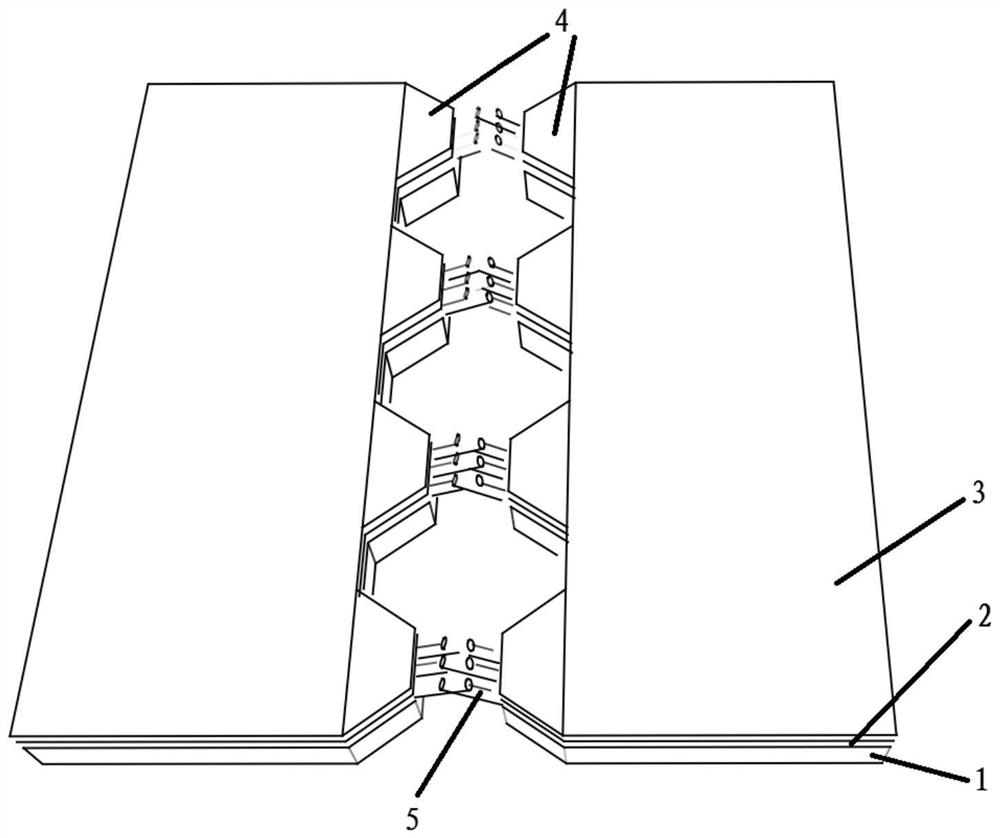

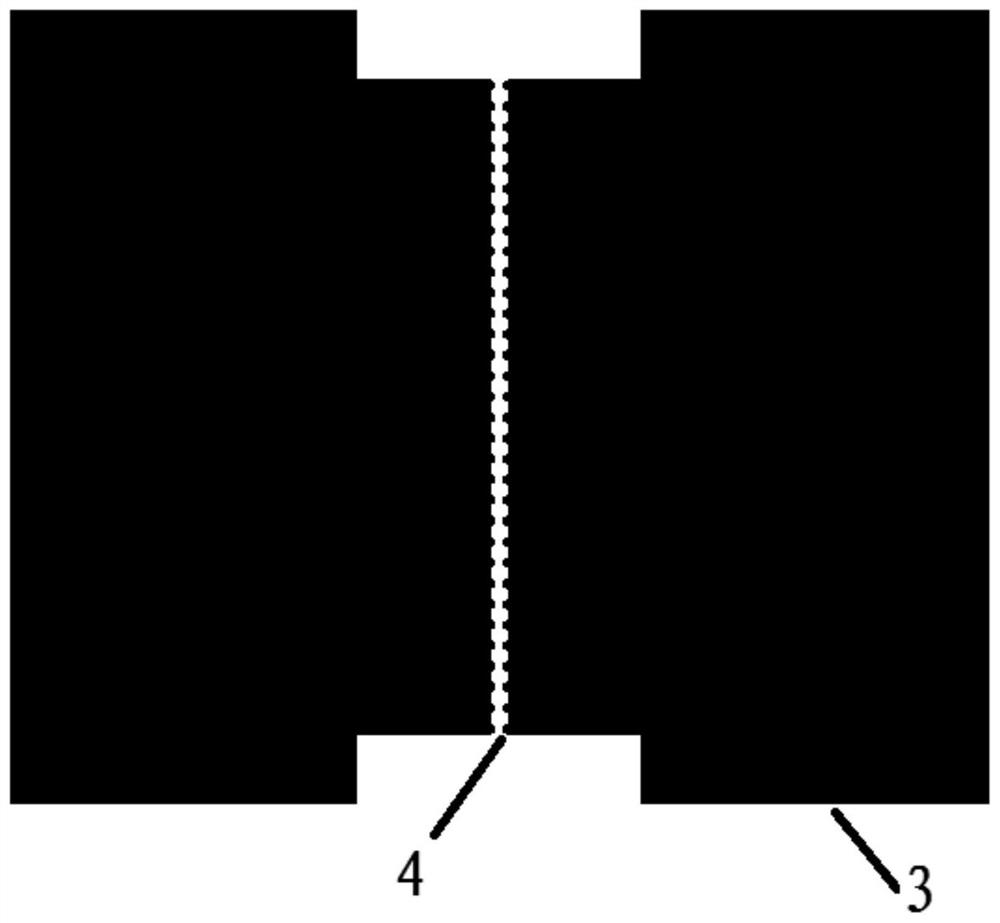

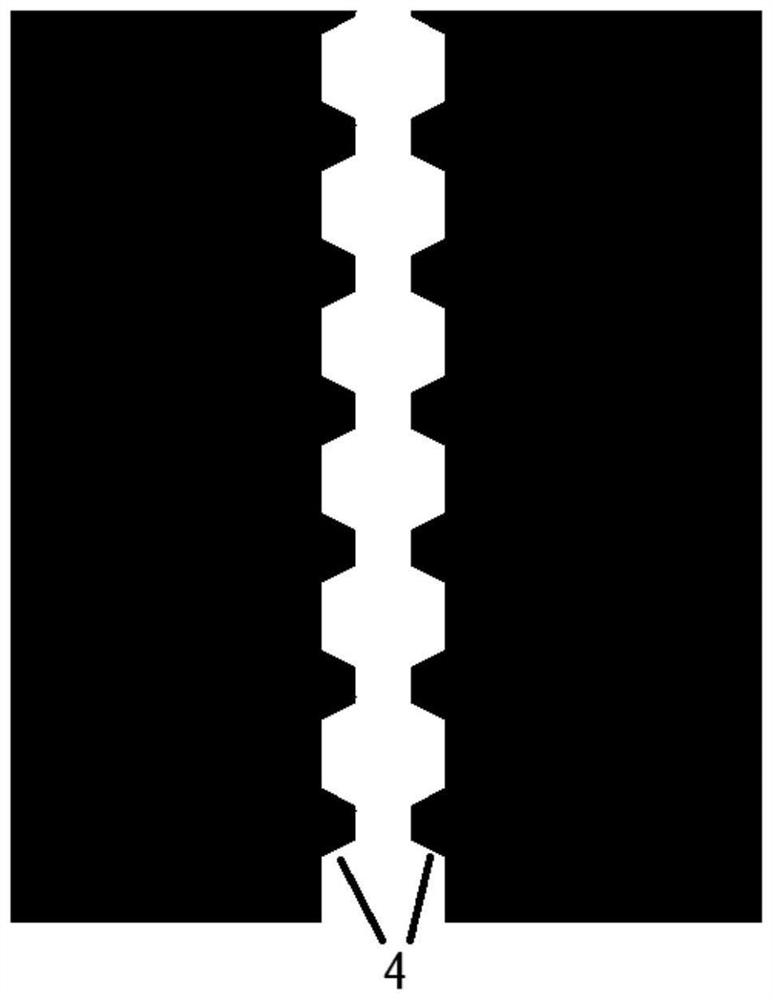

[0097] Using electron beam direct writing technology or laser direct writing technology, a photoresist plate is prepared according to the layout, and the shape of the layout is the shape of a sawtooth electrode.

[0098] SiO with a thickness of 300nm is oxidized on the surface of a silicon (Si) sheet by high temperature oxidation 2 layer, will have silicon dioxide (SiO 2 ) layer of Si sheet as electrode substrate, SiO 2 The layer is an insulating isolation layer.

[0099] First, wash the electrode substrate twice with acetone, then wash the electrode substrate twice with ethanol, and finally wash the electrode substrate twice with deionized water. Cover the photolithographic plate on the cleaned electrode substrate, and use ultraviolet lithography technology to photolithographically publish the pattern on the electrode substrate.

[0100] Use the radio frequency magnetron sputtering method to sputter a zinc oxide seed layer with a thickness of 95nm on the photolithographic ...

Embodiment approach 2

[0108] Using electron beam direct writing technology or laser direct writing technology, a photoresist plate is prepared according to the layout, and the shape of the layout is the shape of a sawtooth electrode.

[0109] SiO with a thickness of 300nm is oxidized on the surface of a silicon (Si) sheet by high temperature oxidation 2 layer, will have silicon dioxide (SiO 2 ) layer of Si sheet as electrode substrate, SiO 2 The layer is an insulating isolation layer.

[0110] First, wash the electrode substrate twice with acetone, then wash the electrode substrate twice with ethanol, and finally wash the electrode substrate twice with deionized water. Cover the photolithographic plate on the cleaned electrode substrate, and use ultraviolet lithography technology to photolithographically publish the pattern on the electrode substrate.

[0111] Use the radio frequency magnetron sputtering method to sputter a zinc oxide seed layer with a thickness of 115nm on the photolithographic l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com