A kind of substrate for micro-led display panel and manufacturing method thereof

A technology of a display panel and a manufacturing method, which is applied to the side metal structure field of a micro LED display, can solve the problems of large seams, falling off, and easy metal expansion of the splicing screen, so as to ensure the accuracy and avoid the side glue patterning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] By the following Figure 2-9 The method of manufacturing the first embodiment of the present invention is described:

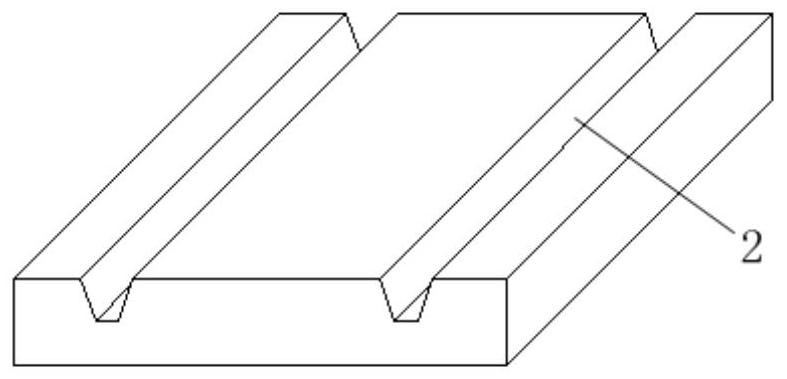

[0064] Preparing a glass substrate ( figure 2 );

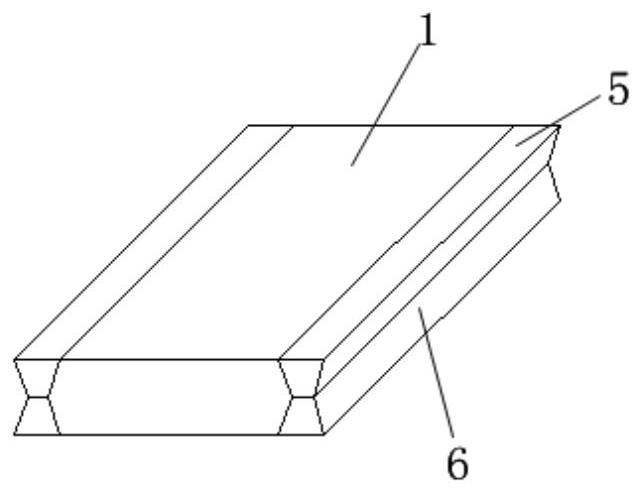

[0065] 2. The first strip 2 having a certain depth is opened in the first surface of the glass substrate 1, wherein the first stripping hole 2 is parallel to the separation of a distance ( image 3 );

[0066] 3. A metal layer 3 is formed on the first surface of the glass substrate in the first surface of the glass substrate, wherein the metal layer is filled with the first strip 2 ( Figure 4 .

[0067] 4. A photoresist 4 is formed on the surface of the metal layer 3, which is exposed to developed (e.g., a mask plate), wherein the first portion of the photoresist first portion 41 remains, other positions Eliminate Figure 5 .

[0068] 5. Etching the substrate such that the metal layer at the first strip 2 position is retained to form a first metal strip 5, after removing the photoresist of the surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com