Current sensor probe and assembling method thereof

A technology of a current sensor and an assembly method, applied in the field of sensors, can solve the problems of cumbersome wiring process, low production efficiency, low assembly efficiency, etc., and achieves the effects of solving easily broken wires, saving labor costs, and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

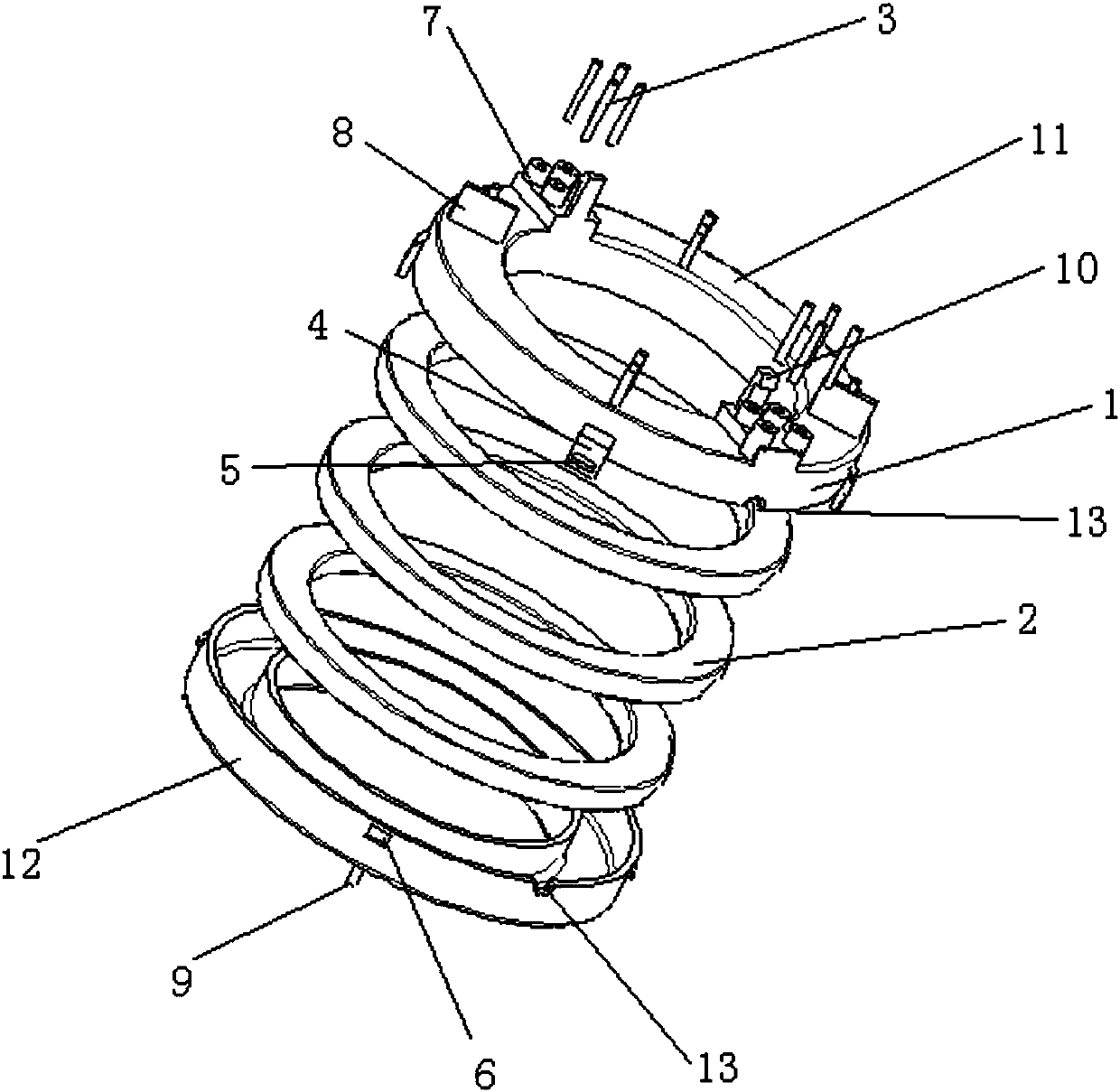

[0032] A current sensor probe includes a support frame 1, an iron core 2, a winding and pins 3. The support frame 1 includes an upper cover 11 and a lower cover 12, the outer wall of the upper cover 11 is provided with a first protrusion 4, the first protrusion 4 exceeds the lower surface of the upper cover 11 and extends downward, and the outer side of the lower cover 12 The wall is provided with a second protrusion 6 at the position corresponding to the protrusion of the outer side wall of the upper cover 11, and the position where the first protrusion 4 extends downward beyond the lower surface of the upper cover 11 is provided to match the size of the second protrusion 6. The first hole 5 of the upper cover 11 and the lower cover 12 are snap-connected by the first hole 5 on the first protrusion 4 and the second protrusion 6 on the lower cover 12 to form an accommodating cavity. The shape of the support frame 1 is ring or square, and the shape of the iron core 1 is consiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com