Resource scheduling method and system based on multiple process models

A resource scheduling and process model technology, applied in the software field, can solve the problems of lack of downhole production resources, process scheduling optimization, lack of application and exploration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in more detail below in conjunction with specific embodiments and accompanying drawings.

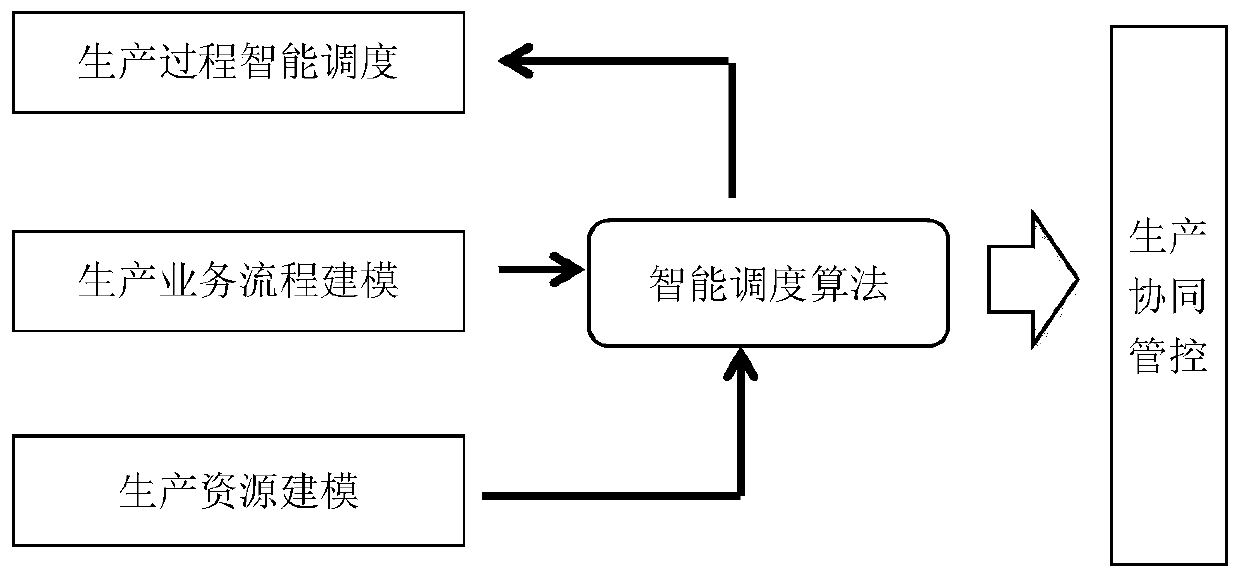

[0080] Taking the production resource model and business process model as input, through the matching of computing capacity conditions and limiting factors, an intelligent production scheduling algorithm is formed, and the scheduling model is output.

[0081] (1) Develop a modeling tool for the mine safety production underground dispatching model. Through the modeling tool, the equipment parameters and quantities can be customized according to the actual situation of the mine, and the modeling process of the mine safety production underground dispatching system can be realized.

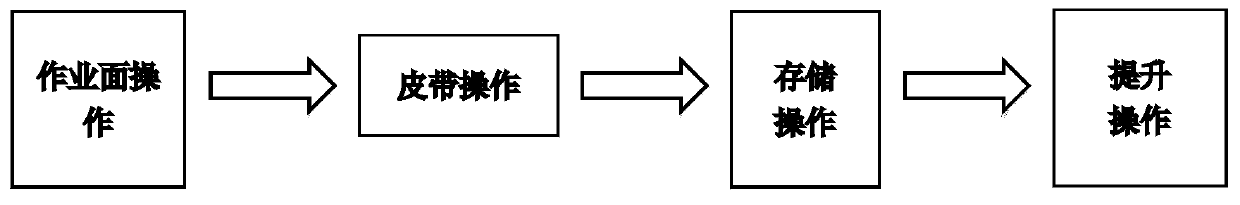

[0082] (2) Provide a problem constraint description interface in json format, which is used to describe the constraints of the specific problems concerned by downhole scheduling, such as the Machine class of the working face, the Pipe class of the transmission belt, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com