Two-stage scheduling method of parallel test tasks facing spacecraft automation test

A technology for automated testing and testing tasks, applied in software testing/debugging, concurrent instruction execution, machine execution devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

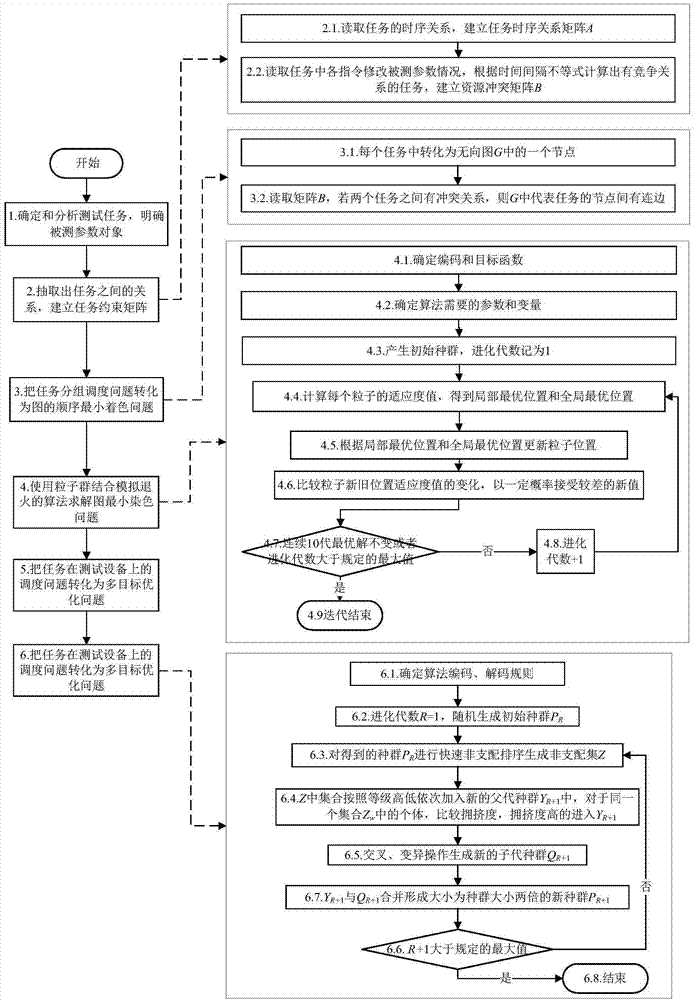

[0032] Hereinafter, the present invention will be described in detail with reference to the drawings and combined with implementation.

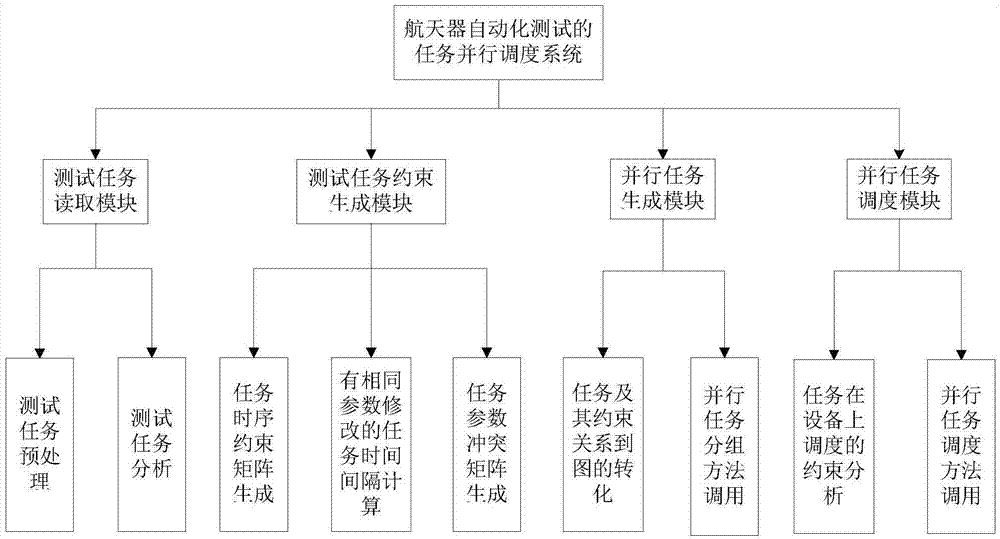

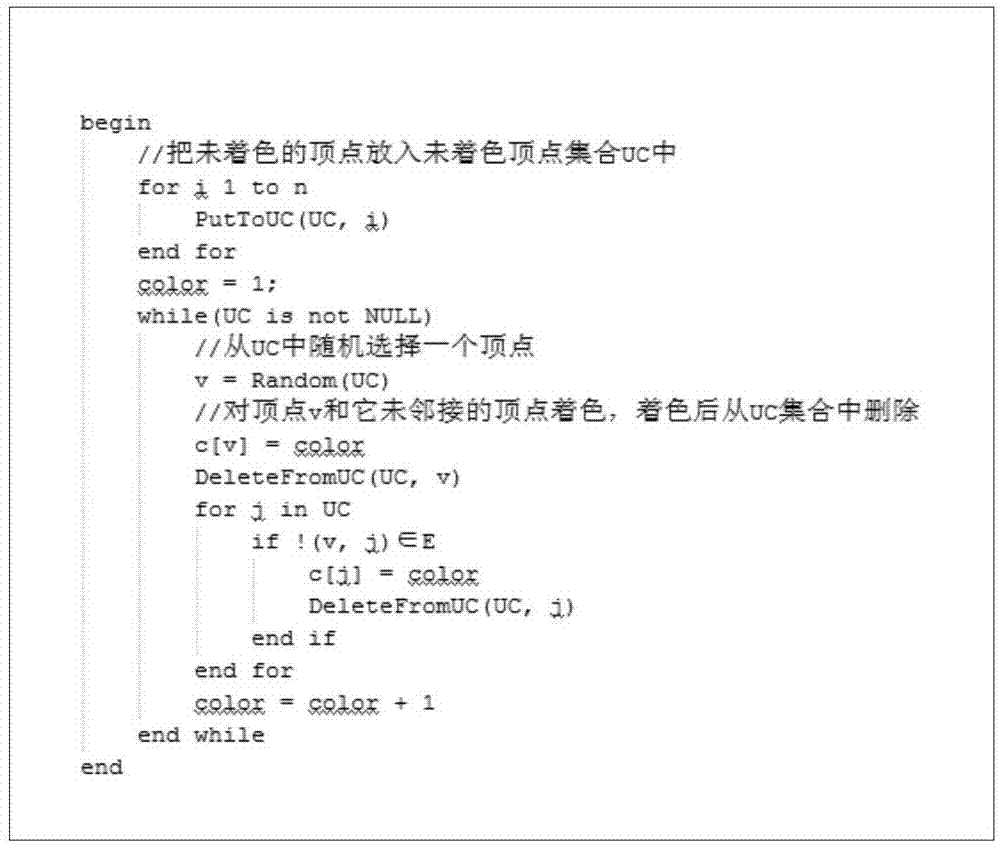

[0033] The two-stage scheduling method for parallel test tasks oriented to the automatic test of spacecraft provided by the present invention, in the first stage, by extracting the spacecraft parameters of each task to modify the requirements and the timing relationship of the tasks, a task constraint relationship suitable for the automatic test of spacecraft is established. , using the idea of combining particle swarm and simulated annealing to generate parallel test task groups without conflicts between each other; in the second stage, the test tasks obtained by grouping the first stage are allocated on the limited test equipment, and the multi-constraint The optimization problem is transformed into a multi-objective optimization problem, and the improved multi-objective optimization NSGA-II algorithm (non-dominated sorting genetic algorit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com