Construction process of dry-work hole cast-in-place pile penetrating through karst cave

A construction technology and dry operation technology, applied in sheet pile walls, soil protection, foundation structure engineering, etc., can solve the problems of high cost, difficult construction, difficult pouring of pile concrete in karst cave sections, etc., and achieve low cost and good plasticity , small disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

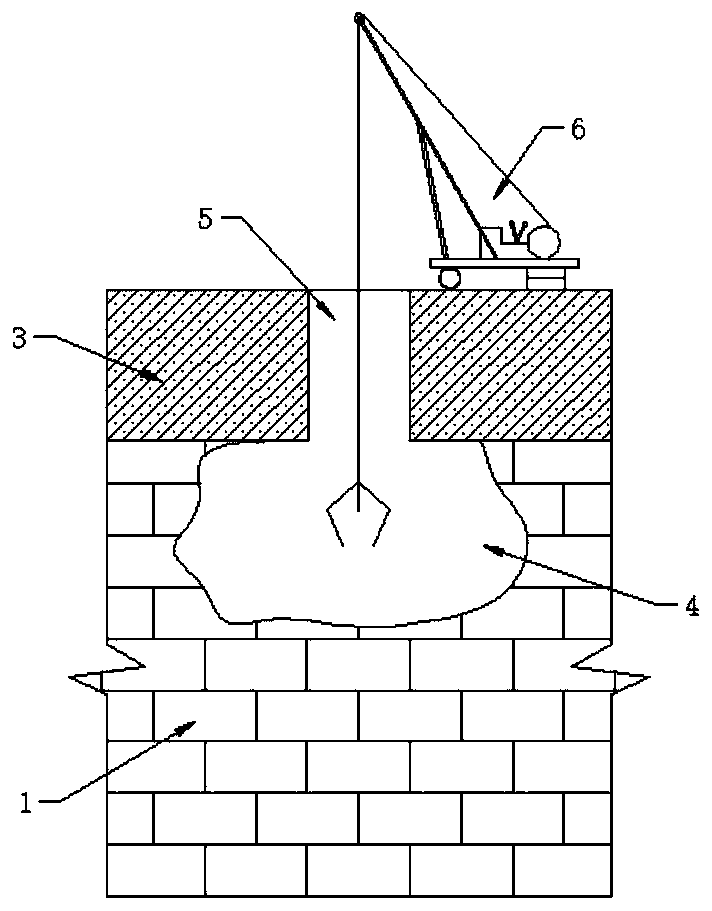

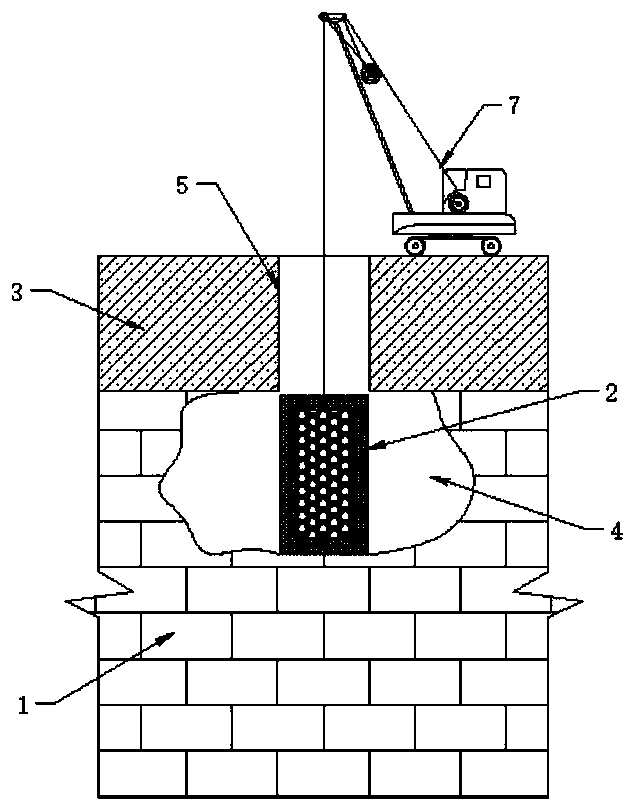

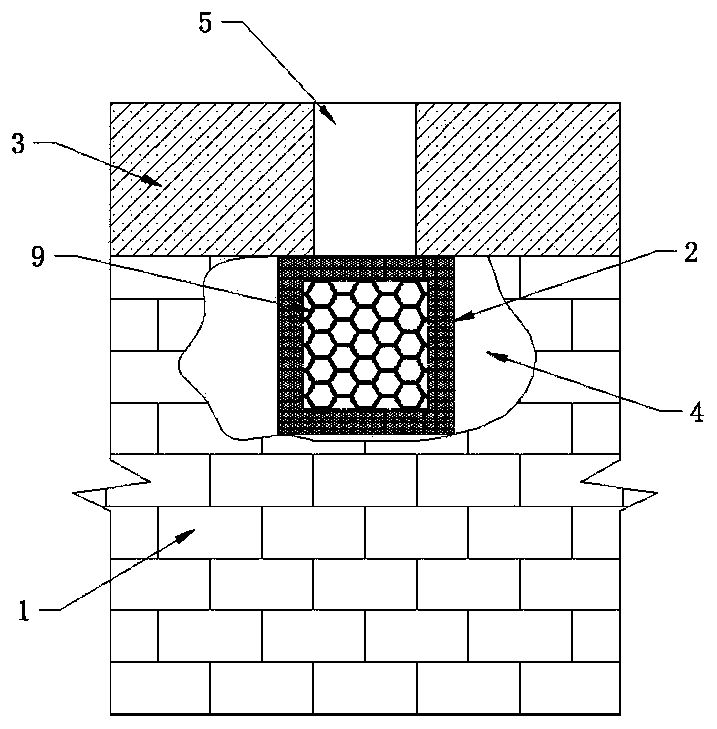

[0038] Below in conjunction with accompanying drawing, device of the present invention and implementation step are further described:

[0039] Such as Figure 8 to Figure 10 As shown, a filling body used for the construction of cast-in-situ piles passing through karst caves, Figure 10 is the packing body 2 in the compressed state, Figure 8 , 9 Fill body 2 for the extended state. The filling body 2 is composed of inner and outer parts, and the inner core 2.3 is a hollow "honeycomb" space network porous structure processed by filling materials. The outside is a protective structure with a certain thickness, that is, the shell 2.1. In the embodiment of the present invention, sponge is used as the material for preparing the inner core 2.3; pearl cotton is used as the outer wall (shell) material of the filling body 2, which has many advantages such as moisture-proof, shock-proof, good plasticity, strong toughness, strong chemical resistance, and environmental protection.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com