Production method of novel lightweight high-strength shock-resistant fireproofing inner wall board

A production method and technology of interior wall panels, which are applied in the production of anti-seismic and fireproof interior wall panels, in the new light-weight and high-strength field, can solve the problems of poor bending resistance, easy damage, energy consumption, and reduced strength, and achieve low manufacturing costs. The effect of convenient and quick construction and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

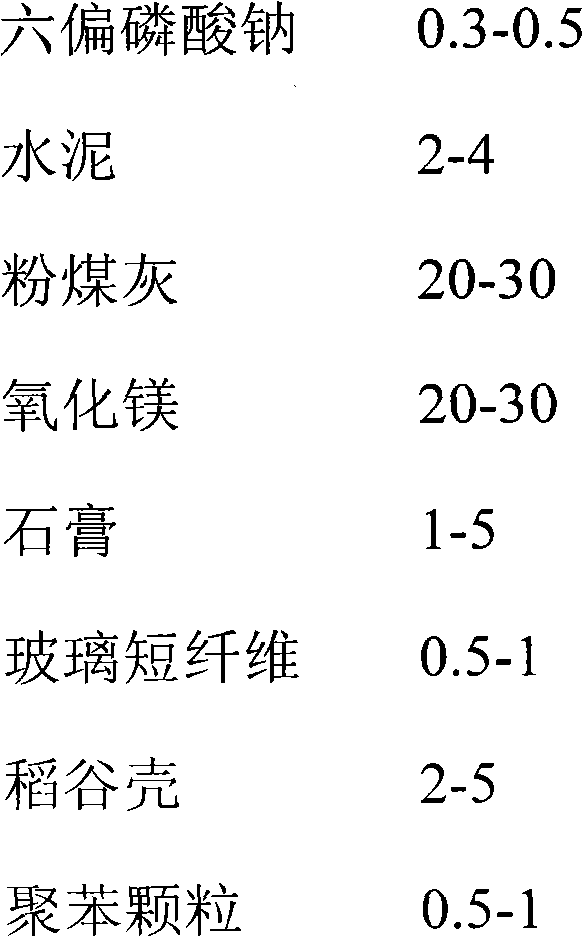

[0010] The following materials are composed by weight percentage:

[0011] Take 29kg of water, 10kg of magnesium chloride, 0.5kg of sodium hexametaphosphate, 3kg of cement, 20kg of fly ash, 30kg of magnesium oxide, 3kg of gypsum, 1kg of short glass fiber, 3kg of rice husk, and 0.5kg of polystyrene particles. After uniformity, it is poured into a pre-prepared mold to be vibrated, cured at room temperature for 6-10 hours, and finally demolded and trimmed to be a cost product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com