Fabricated concrete composite wallboard structure

A composite wallboard and concrete technology, which is applied to building components, building structures, buildings, etc., can solve the problems of large deformation of external thermal insulation wallboards, reduced energy-saving effects, fires, etc., to improve the resistance to lateral force and overturning force, Integrate structure and function, improve the effect of scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical content of the present invention will be further described below, but it is not intended to limit the essence of the present invention.

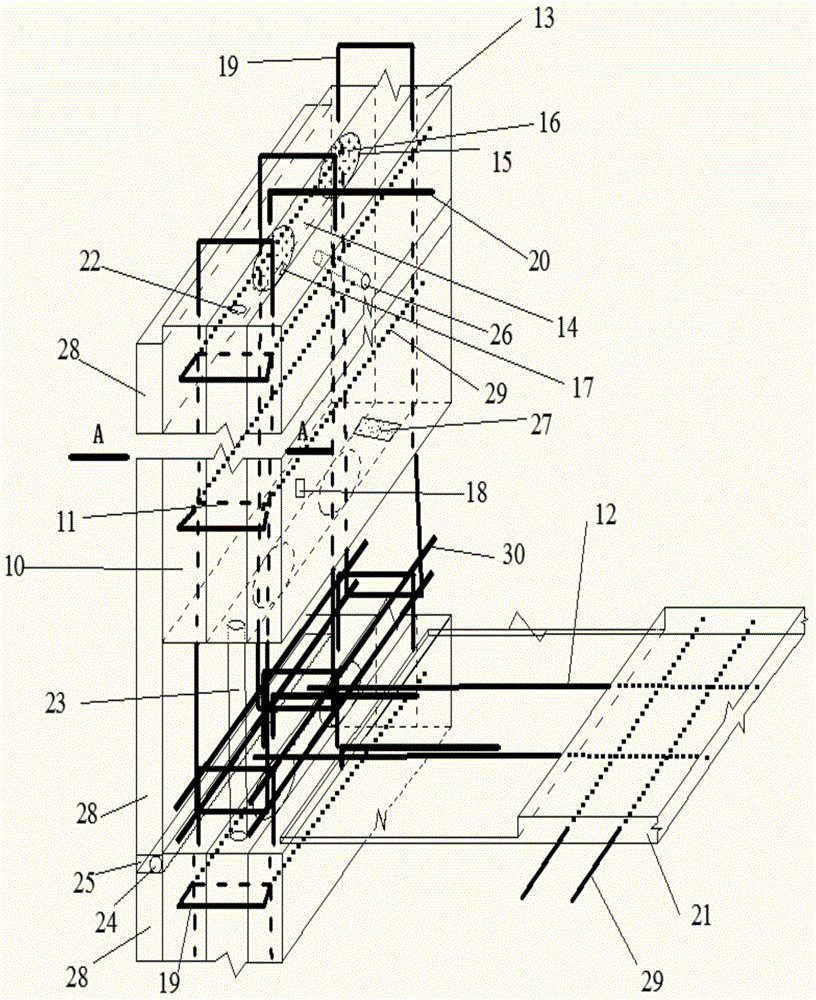

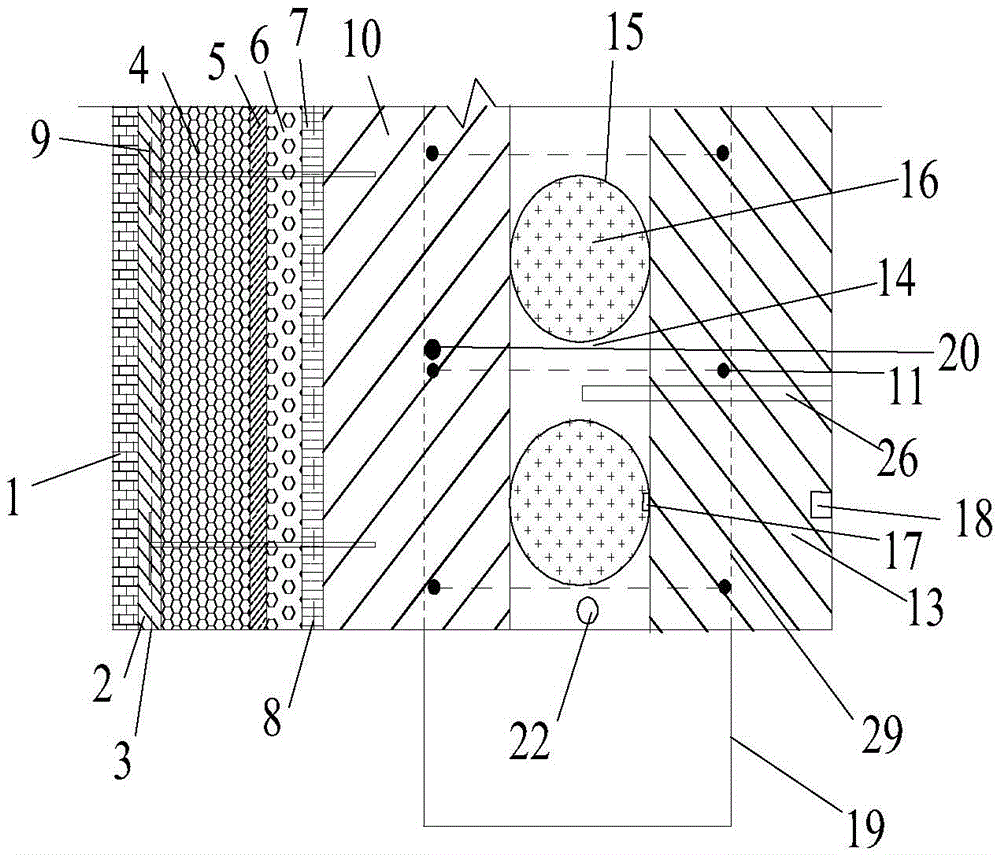

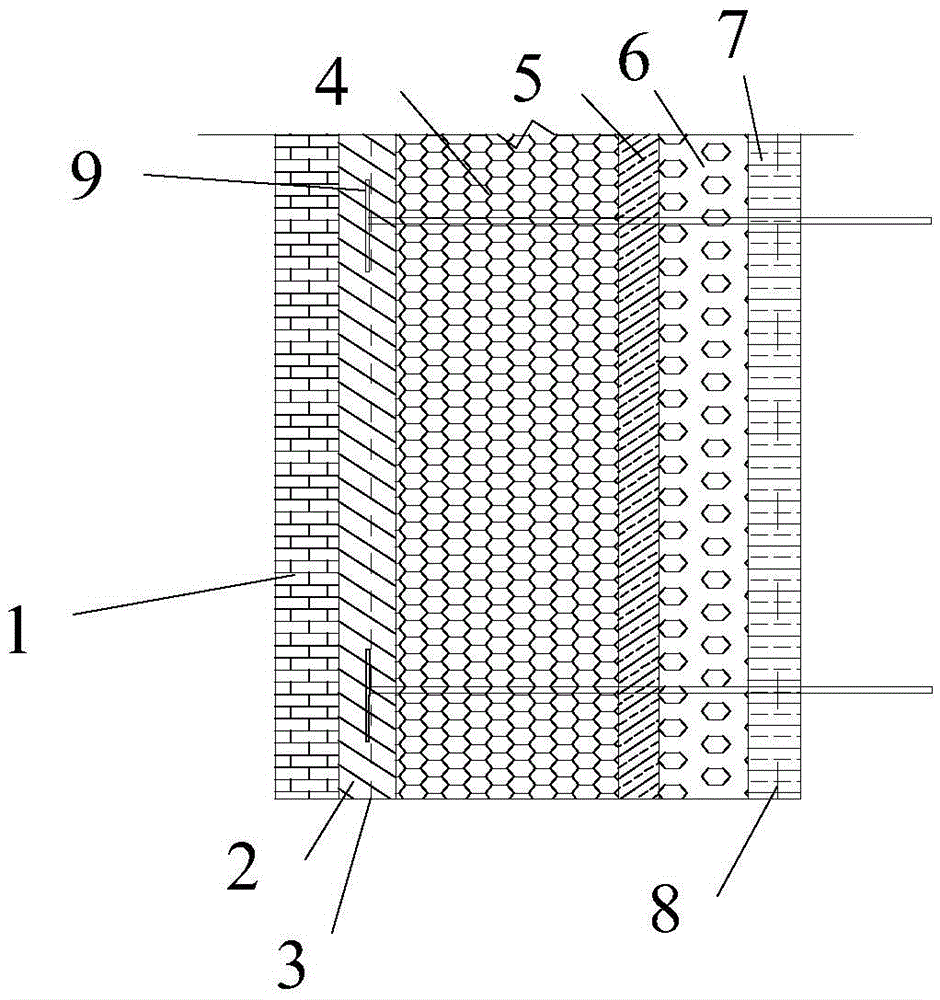

[0044] figure 1 It is a structural schematic diagram of the assembled concrete multifunctional composite wall panel structure system of the embodiment of the present invention; figure 2 It is a schematic diagram of the wall panel cross section A-A of the assembled concrete multifunctional composite wall panel of the embodiment of the present invention; image 3 It is a schematic cross-sectional view of the functional composite layer of the present invention; Figure 4 It is one of the schematic diagrams of the structure of the fixing part of the present invention; Figure 5 It is the second structural diagram of the fixing part of the present invention; Figure 6 It is the third structural diagram of the fixing part of the present invention.

[0045] Such as figure 1 As shown, the prefabricated concrete composite w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com