Mixed assembly type steel structure building and construction method thereof

A technology of mixed assembly and construction methods, applied in the direction of building structure, construction, building components, etc., can solve the problems of difficult quality assurance, high material cost, lack of construction space, etc., achieve high lateral force resistance, and save formwork support , Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

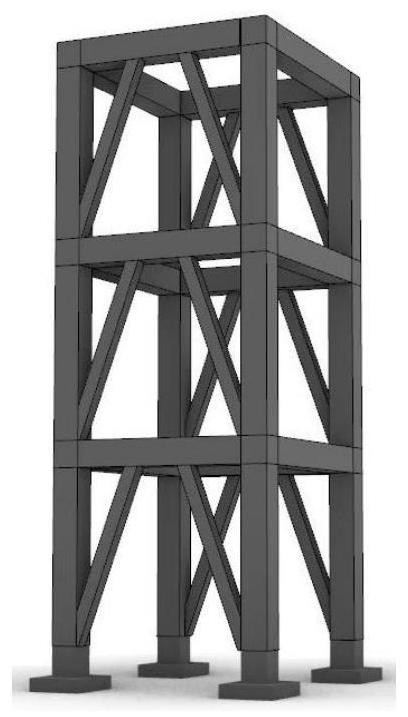

[0032] see figure 1 , Figure 3 to Figure 7 . A hybrid prefabricated steel structure building according to the embodiment of the present invention, such as figure 1 As shown, it includes odd-numbered columns 6 , walls and even-numbered modular units 4 . First, the entire mixed building is divided into odd-numbered and even-numbered floors according to the natural number of floors. After foundation 7 is completed, odd-numbered floors are firstly installed with odd-numbered columns 6, and then even-numbered modular units 4 are hoisted. through different nodes ( Figure 3 to Figure 7 ) are connected, the columns of the even-numbered layer module unit 4 are set to the module unit column extension section 5, so the connection nodes of all columns ( Figure 3 to Figure 7 ) are set in the odd-numbered layer space area, so that the connecting nodes ( Figure 3 to Figure 7 ) can be exposed for easy connection of nodes ( Figure 3 to Figure 7 ) construction and ensure the construc...

Embodiment 2

[0034] see figure 2 , Figure 3 to Figure 7 . Another hybrid prefabricated steel structure building according to the embodiment of the present invention, such as figure 2 As shown, it includes odd-numbered columns 6 , supports, walls and even-numbered modular units 4 . First, the entire mixed building is divided into odd-numbered and even-numbered floors according to the natural number of floors. After foundation 7 is completed, odd-numbered floors are firstly installed with odd-numbered columns 6, and then even-numbered modular units 4, even-numbered modular unit columns 10, and odd-numbered columns are hoisted. 6 through the corresponding node ( Figure 3 to Figure 7 ) is connected, the column of the module unit 4 is set to the column extension section 5 of the module unit, so the connection nodes of all the columns ( Figure 3 to Figure 7 ) are set in the odd-numbered layer space area, so that the connecting nodes ( Figure 3 to Figure 7 ) can be exposed for easy con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com