Double-stage sleeve-type automatic jacking device

A jacking device, a sleeve-type technology, applied in the direction of the lifting device, etc., can solve the problems of weak synchronization, low degree of automation, poor controllability of lifting speed, etc., and achieve the effect of enhanced lateral force resistance and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

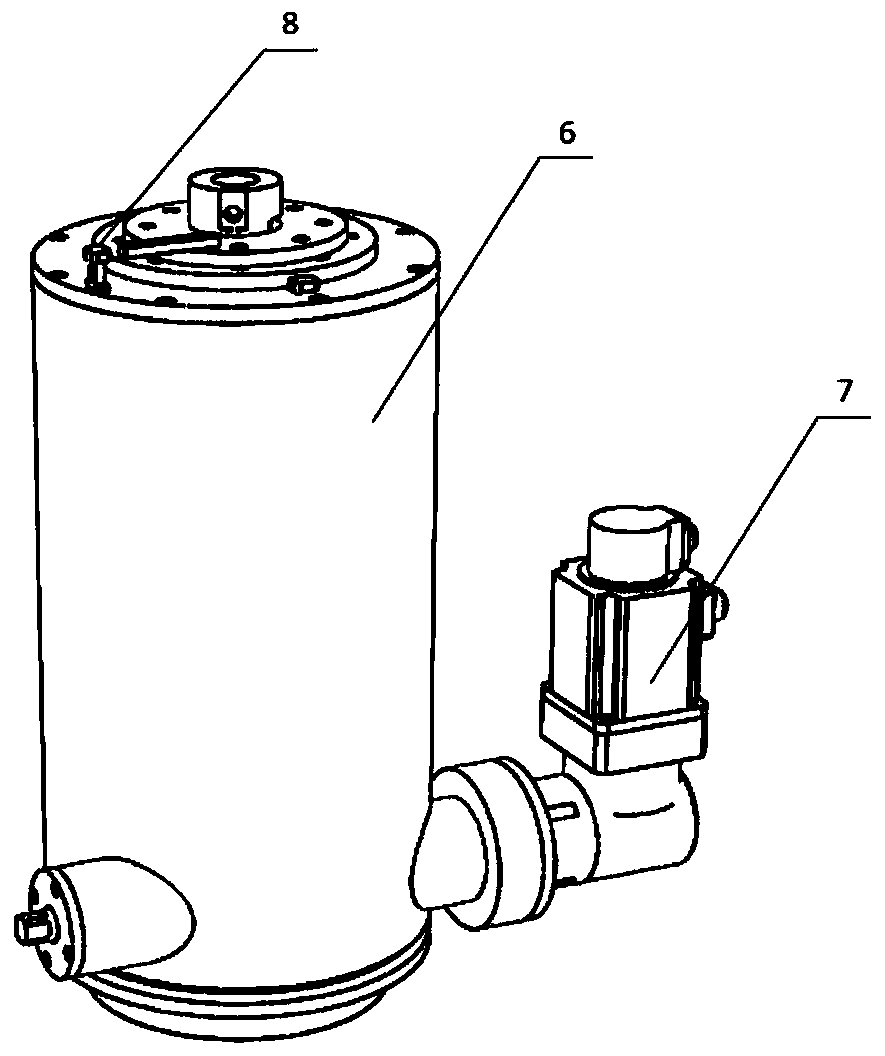

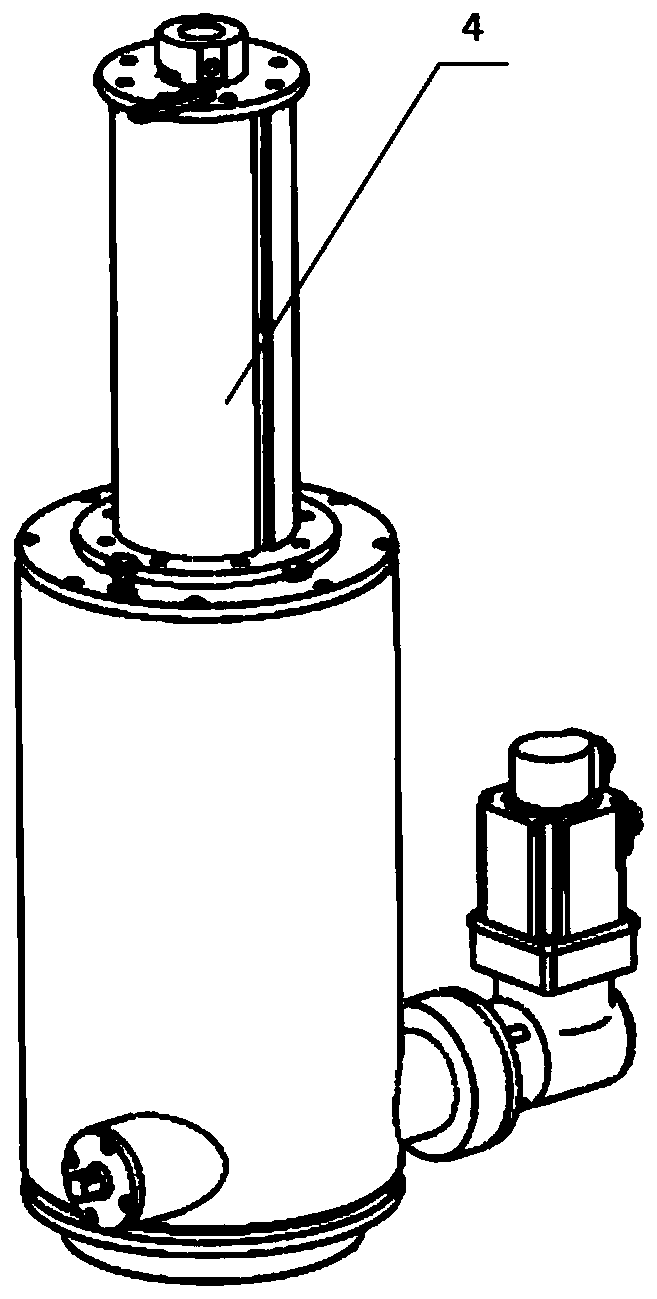

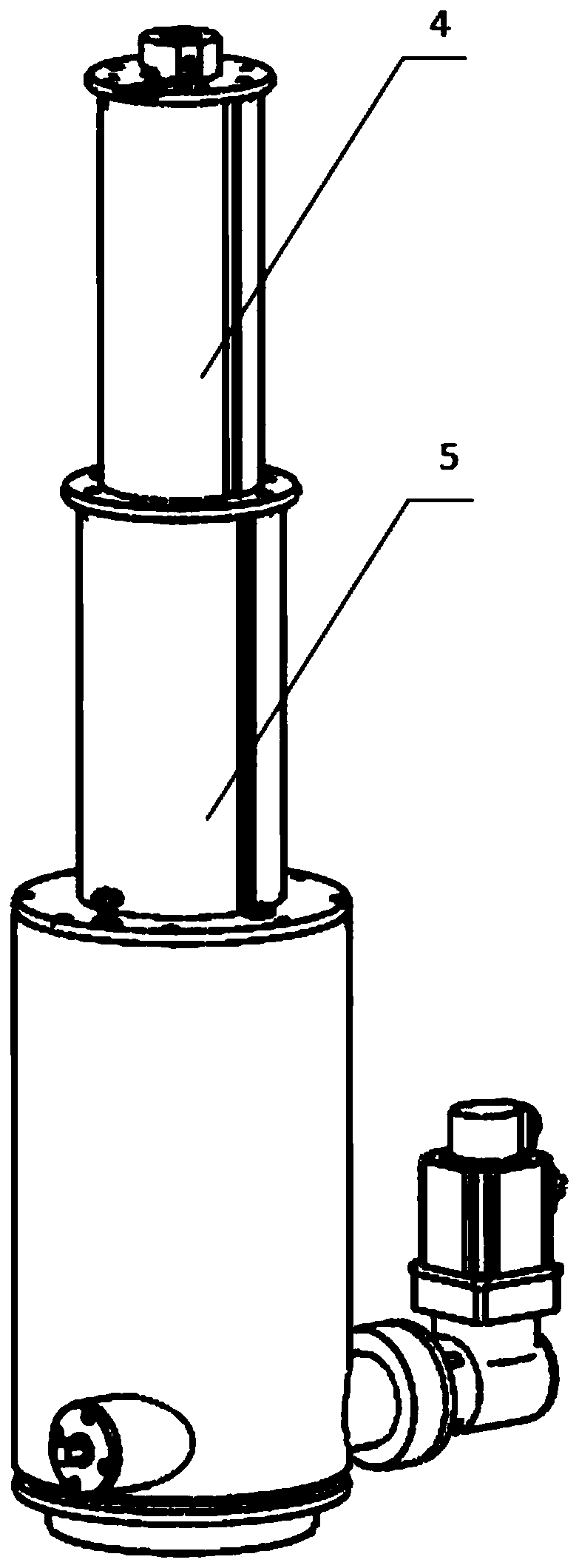

[0033] like figure 1 , 2 , 3, 4, 5, and 6, this embodiment discloses a two-stage sleeve-type automatic jacking device mainly composed of a primary screw 1, a secondary screw 2, a rotating cylinder 3, and a primary guide cylinder 4 , Secondary guide cylinder 5, outer cylinder body 6, servo power unit 7 and diffuse reflection laser photoelectric switch 8.

[0034] The primary lead screw 1 is an ordinary trapezoidal lead screw, the upper end of which is connected with a force sensor, and the force sensor is finally connected with the fuselage.

[0035] The secondary lead screw 2 is a sleeve-type lead screw, the inner wall and the outer wall are threaded, the inner wall is threaded with the primary lead screw 1, and the outer wall is threaded with the rotating cylinder 3.

[0036] The bottom of the rotating cylinder 3 is equipped with a worm gear, and the torque and speed are applied through the servo motor and the reducer.

[0037] The first-stage guide cylinder 4, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com