Preparation method of welded joint of aluminum pipes

A technology for welding joints and aluminum pipes, which is applied in welding equipment, pipes/pipe joints/fittings, resistance welding equipment, etc., can solve the problems of aluminum pipe joint oxidation and other problems, and achieve the effects of anti-seismic joints, no casting structure, and wide welding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preparation method of the aluminum pipe welded joint of the present embodiment comprises the following steps:

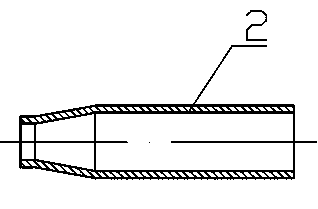

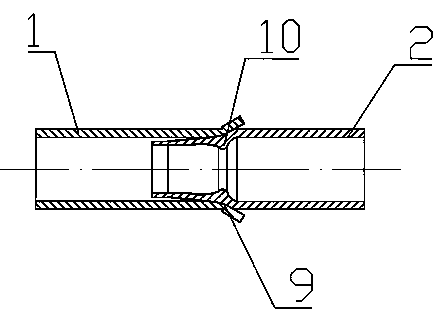

[0029] The first step is shrinking forming: take two sections of aluminum tubes, use one of them as the insertion aluminum tube 2, insert one end of the aluminum tube 2 and shrink it to form a straight tubular port with stepped diameter reduction; the other section of the aluminum tube remains in its original shape as a sleeve Connect aluminum tube 1;

[0030] The second step, pretreatment: before welding, carry out surface treatment on the welding ends of the two sections of aluminum tubes, the treatment method is as follows: alcohol or acetone ultrasonic vibration cleaning→alkaline cleaning→acid cleaning→water washing;

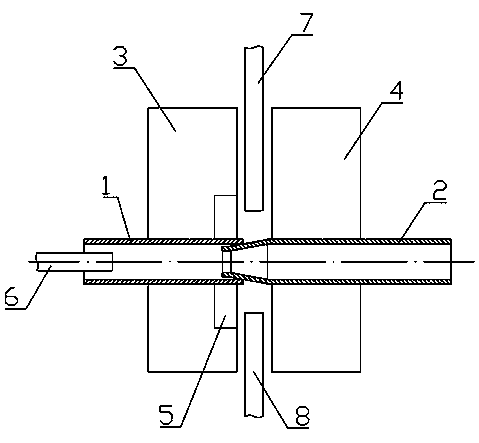

[0031] The third step, positioning: put the sleeved aluminum tube 1 on the fixed electrode group 3, and fix it with a high-pressure cylinder; put the inserted aluminum tube 2 on the moving electrode 4, and extend the front end into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com