Improved section bar internal local reinforcing structure for automobile body structure

A locally reinforced and improved technology, applied in the field of auto parts, can solve the problems of excess performance of non-use parts, limited performance improvement ability, and increase the cost of materials, so as to improve the utilization rate of materials, reduce the weight, and reduce the input cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

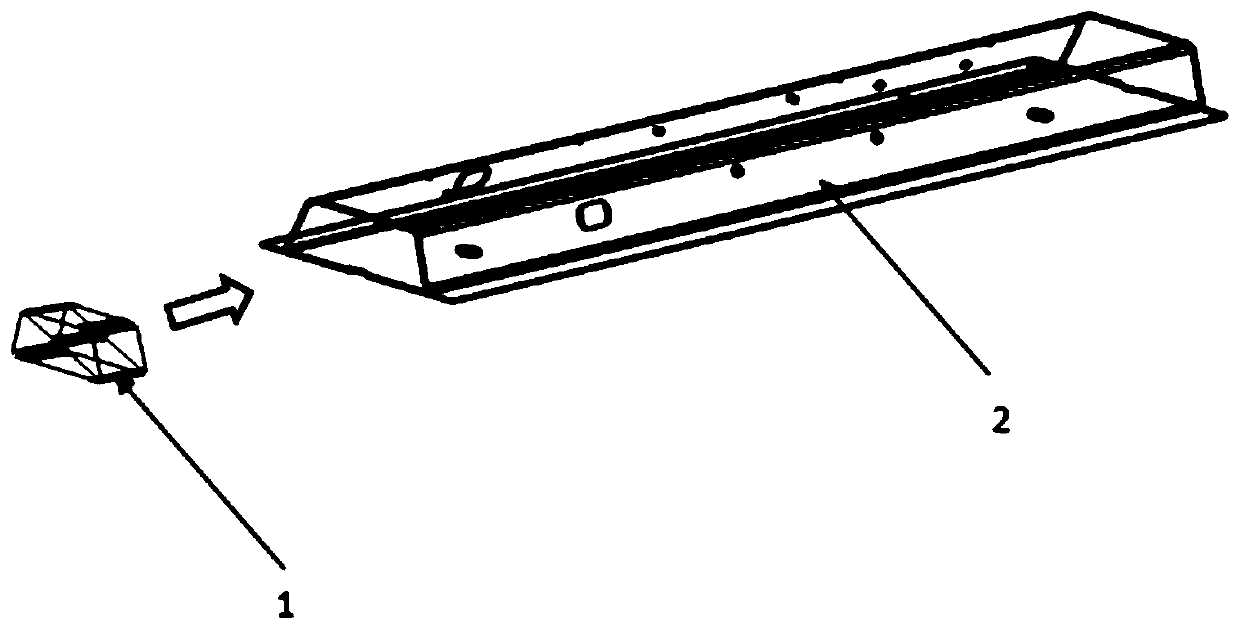

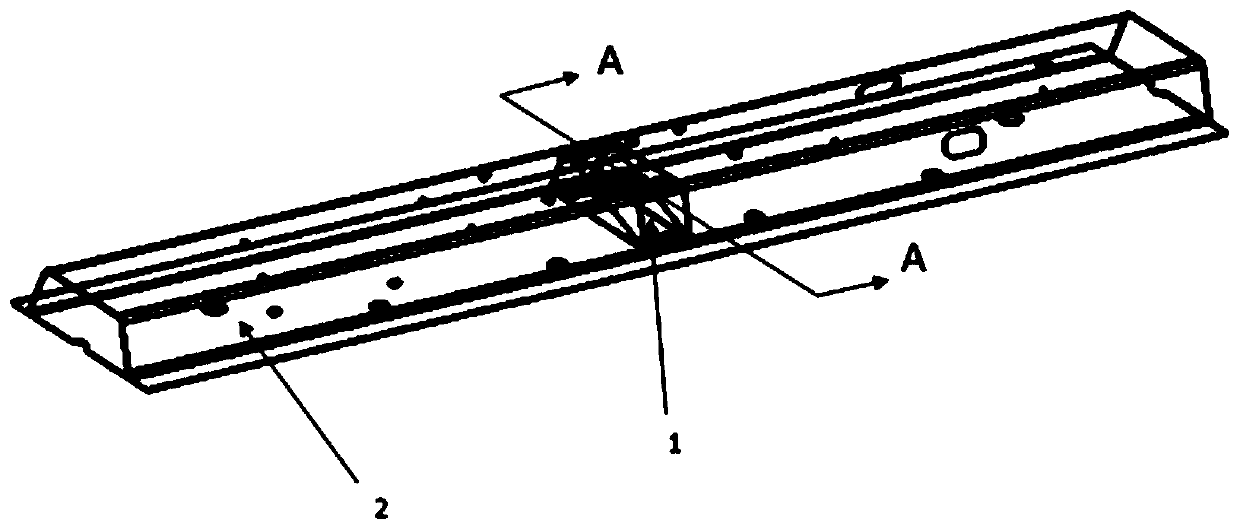

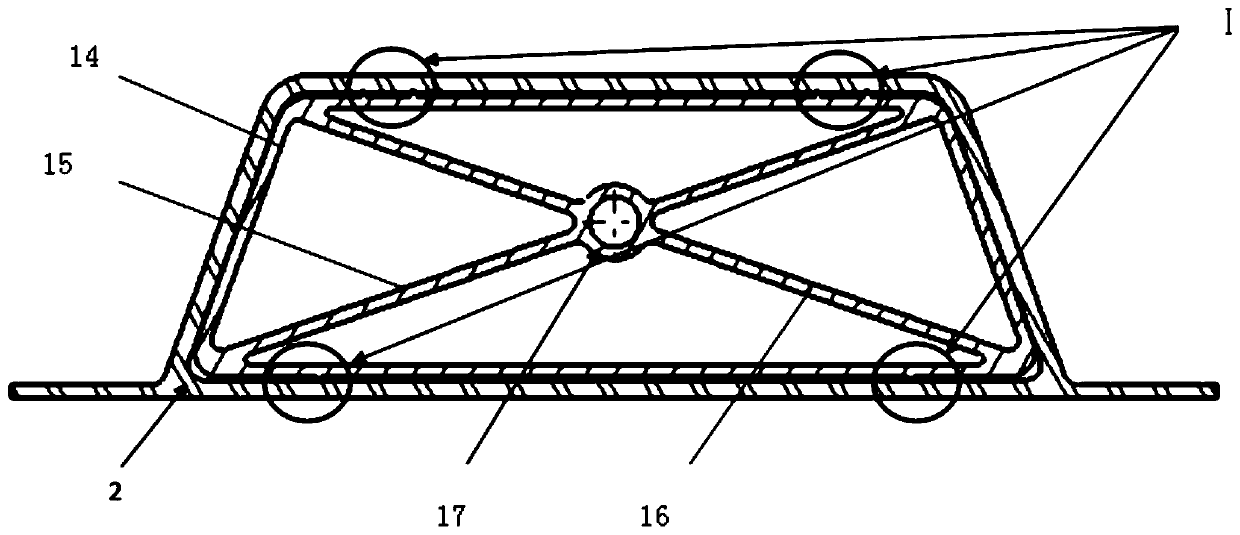

[0026] As shown in the accompanying drawings, the present invention provides an improved profile internal local reinforcement structure, including a reinforcement 1 and a profile body 2. A reinforcement 1 is pressed into the cavity. The reinforcement 1 is a block structure. The reinforcement 1 is used to locally strengthen the profile body 2. The shape of the reinforcement 1 is connected with the inner cavity of the profile body 2. The surface of the reinforcement 1 is provided with interference ribs. 11. The interfering ribs 11 are in a convex shape, and the interfering ribs 11 are against the inner wall of the cavity of the profile body 2, and are attached and connected with the inner wall of the cavity of the profile body 2. Wherein, the left and right sides of the reinforcement 1 are attached to the inner wall of the cavity of the profile body 2, that is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com