Bump type self-locking self-plugging rivet

A blind rivet and self-locking technology, which is applied to rivets, screws, threaded fasteners, etc., can solve the problems of low overall strength, unsafe and reliable connection, and easy loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

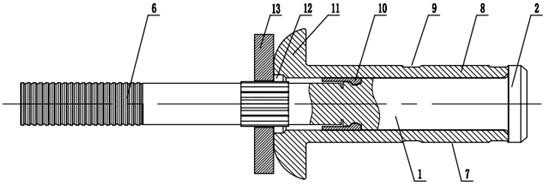

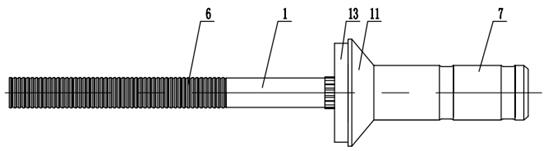

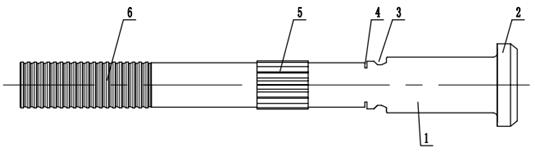

[0023] like figure 1 , 3 , 4, 5, and 6, the bulge-type self-locking blind rivet includes a nail shank 1, and the nail shank 1 is provided with a nail head 2, a locking groove 3, a broken neck groove 4 and a straight grain section 5 in sequence. , the straight section 5 is provided with a resistance washer 13, a nail sleeve 7 is provided between the resistance washer 13 and the nail head 2, and a lock ring 10 is provided between the nail sleeve 7 and the locking groove 3, when assembling , first install the lock ring 10 in the locking groove 3, then put the nail sleeve 7 on the nail rod 1, and finally push the resistance washer 13 into the 5 places of the straight grain section of the nail rod 1 so as to block the nail sleeve 7 to ensure The nail sleeve 7 cannot axially move on the nail rod 1, and finally compresses the nail sleeve 7 to strengthen the tail end and middle part of the nail sleeve 7.

[0024] For the convenience of forming a bulge, the nail sleeve 7 includes a n...

Embodiment 2

[0030] like Figure 2-6 As shown, the bulge-type self-locking blind rivet includes a nail shank 1, and the nail shank 1 is provided with a nail head 2, a locking groove 3, a broken neck groove 4 and a straight grain section 5 in sequence, and the straight grain section 5 is provided with a resistance washer 13, a nail sleeve 7 is provided between the resistance washer 13 and the nail head 2, and a lock ring 10 is provided between the nail sleeve 7 and the locking groove 3. When assembling, the lock ring 10 is first Install it in the locking groove 3, then put the nail sleeve 7 on the nail rod 1, and finally push the resistance washer 13 into the straight grain section 5 of the nail rod 1 so as to block the nail sleeve 7, so as to ensure that the nail sleeve 7 cannot be placed on the nail rod. The rod 1 moves axially, and finally presses on the nail sleeve 7 to strengthen the tail end and the middle of the nail sleeve 7 .

[0031] For the convenience of forming a bulge, the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com