A kind of composite material shell and preparation method thereof

A composite material and composite material layer technology, applied in the field of composite material shell and its preparation, can solve the problems of huge investment in equipment, heavy weight, and low structural efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention also provides a method for preparing the above-mentioned composite material shell, comprising the following steps:

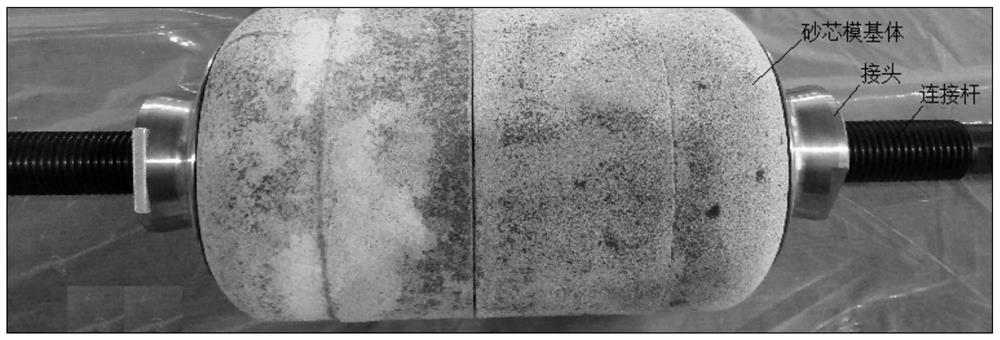

[0030] Prepare the sand core mold matrix, pre-embed at least one joint on one end of the sand core mold matrix, and then assemble with the connecting rod to obtain the sand core mold,

[0031] Spray the inner lining layer material on the outer surface of the sand core mold, heat and solidify for the first time, and cool down to obtain the inner lining layer.

[0032] The composite material layer is made by winding the prepreg tape on the outer surface of the inner liner,

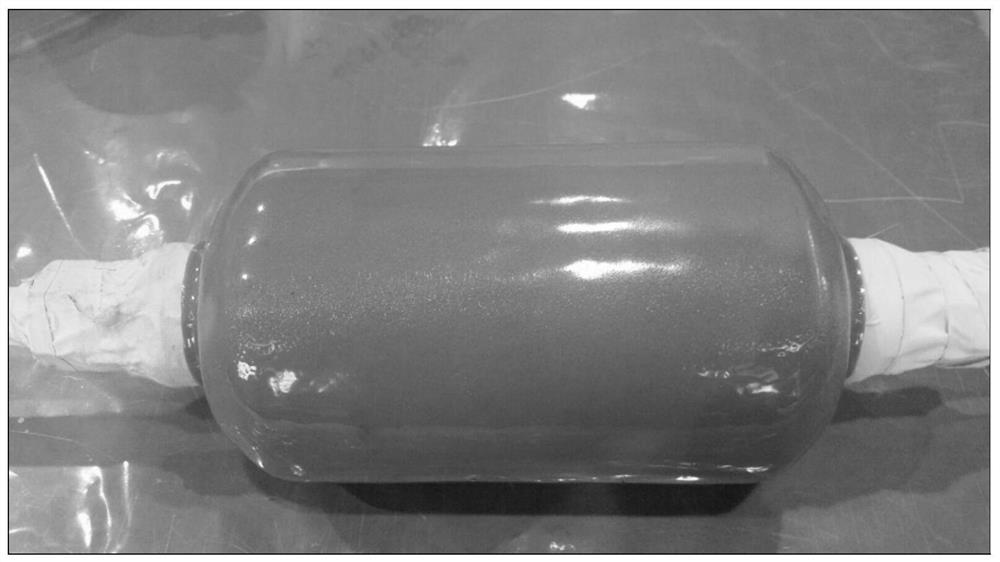

[0033] Wrap the heat-shrinkable tape on the outer surface of the composite material layer to make the heat-shrinkable tape layer, heat and solidify and cool for the second time,

[0034] Remove the surface heat-shrinkable tape layer, remove the connecting rod, and rinse the inner sand core mold base with hot water to obtain a composite material s...

Embodiment 1

[0053] A composite shell

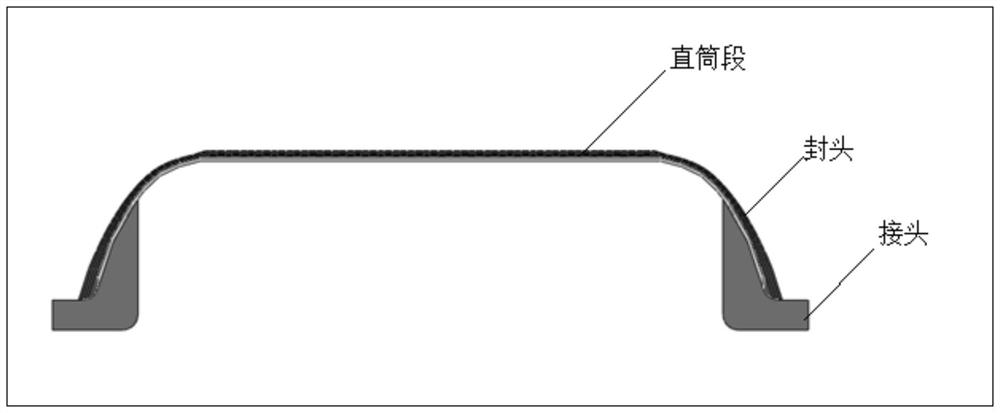

[0054] see figure 1 , the structure of the composite material shell includes: a barrel section and at least one joint for medium in and out provided on one end of the barrel section. Among them, the cylinder body section is a cylindrical structure of revolution, which is composed of a straight cylinder section and heads at both ends of the straight cylinder section, and the shape and surface curve of the head is an ellipse.

[0055] The composition of the barrel section of the composite material shell includes: an inner lining layer and a composite material layer on the surface of the inner lining layer. Among them, the material of the inner lining layer is silicone rubber, the thickness of the barrel section of the inner lining layer is 2mm, and the thickness of the joint position is 3mm. It is constructed in an alternate winding manner, and the thickness of the composite material layer is 2mm.

Embodiment 2

[0057] A composite shell

[0058] see figure 1 , the structure of the composite material shell includes: a barrel section and at least one joint for medium in and out provided on one end of the barrel section. Among them, the cylinder body section is a cylindrical structure of revolution, which is composed of a straight cylinder section and heads at both ends of the straight cylinder section. The shape and surface curve of the head is spherical.

[0059] The composition of the barrel section of the composite material shell includes: an inner lining layer and a composite material layer on the surface of the inner lining layer. Among them, the material of the inner lining layer is epoxy resin, the thickness of the barrel section of the inner lining layer is 3mm, and the thickness of the joint position is 5mm. It is formed in a helical and alternate winding manner, and the thickness of the composite material layer is 15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com