Ultra-low and large tonnage truck-mounted crane

A truck-mounted crane and large tonnage technology, applied in cranes and other directions, can solve the problem that the height of the whole machine cannot be further reduced, and achieve the effect of saving materials and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

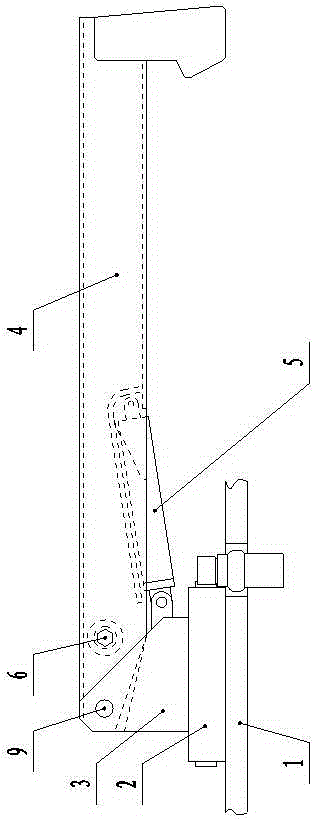

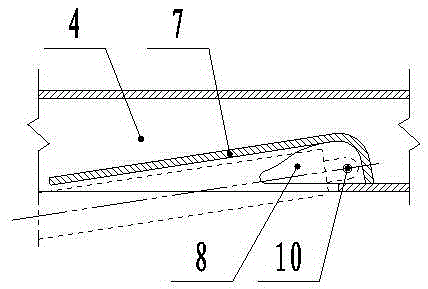

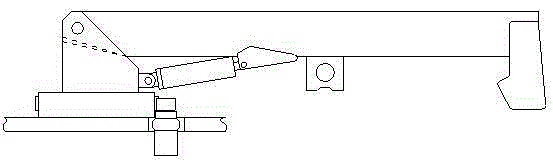

[0014] Such as figure 1 , figure 2 As shown, the ultra-low and large-tonnage truck-mounted crane of the present invention includes a vehicle frame 1, a slewing bearing 2, a column 3, a boom 4, a luffing cylinder 5 and a hydraulic winch 6, and the middle part of the upper plane of the slewing bearing 2 is fixedly equipped with a column 3 And its bottom is installed on the vehicle frame 1, the tail end of the boom 4 is hinged with the top of the column 3, the bottom end of the cylinder body of the luffing cylinder 3 is hinged at the bottom side of the column 3 and the end of the piston rod is hinged on the boom 4, the boom 4 is a hollow structure with a rectangular cross section, the bottom surface of one end of the boom 4 close to the column 3 is open and the bottom surface of the other end is closed, and the hydraulic winch 6 is installed inside the end of the boom 4 close to the column 3. The piston rod end of the oil cylinder 3 stretches into the inside from the bottom op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com