Magnetic grinding device and method suitable for spherical and irregular solid surfaces

A magnetic grinding and irregular technology, which is applied in the direction of machine tools suitable for grinding the edge of workpieces, surface polishing machine tools, grinding machines, etc., can solve the problems of magnetic grinding of spherical and irregular solid surfaces, etc., to increase tumbling and improve The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

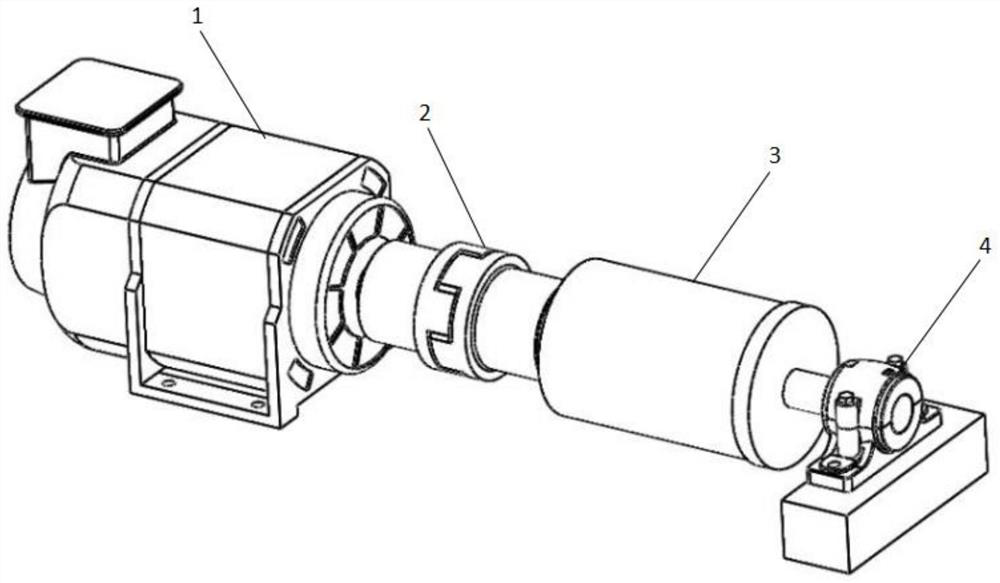

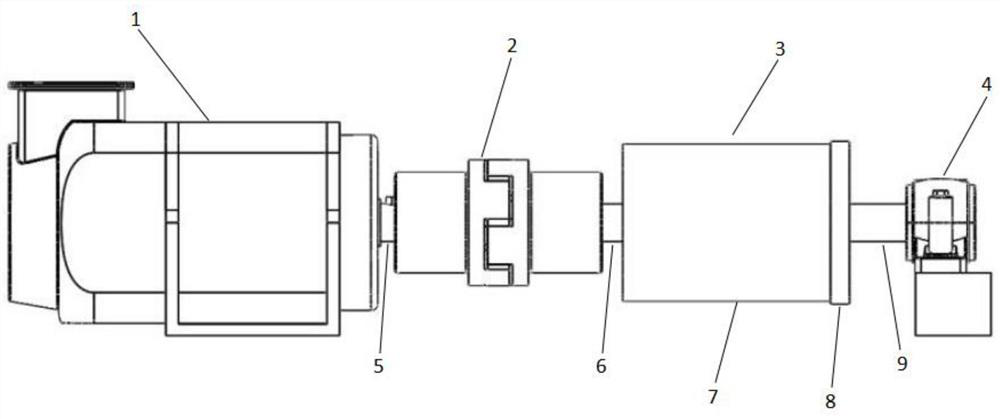

[0025] like figure 1 , figure 2 As shown, the magnetic grinding device suitable for spherical surfaces and irregular solid surfaces includes a servo motor 1 , a coupling 2 , a magnetic grinding cylinder 3 and a bearing seat 4 .

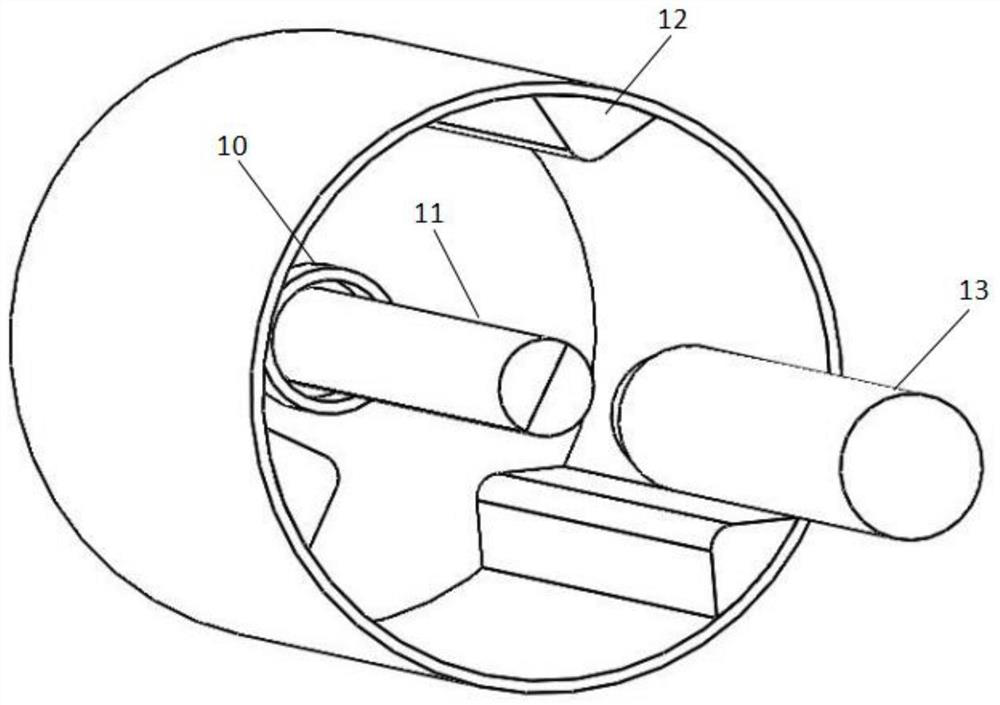

[0026] like image 3 , Figure 4 As shown, the magnetic grinding cylinder 3 includes a transmission shaft 6 , a cylinder 7 , a sleeve seat 10 , a magnetic pole 11 , a sleeve 13 , an end cover 8 and a connecting shaft 9 . The inner wall of the drum 7 is provided with three ribs 12 along the axial direction, and the top corners of the sections of the ribs 12 are triangles with rounded corners. The raised ribs 12 play the role of lifting the abrasive, increasing the tumbling of the abrasive. The magnetic pole 11 is a cylindrical radial magnetic pole.

[0027] The transmission shaft 6 is fixedly connected to one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com