Grinding machine for intelligent carbon skateboard with support auxiliary function and grinding method thereof

An auxiliary function, carbon slide technology, applied in the direction of grinding slides, grinding racks, grinding machines, etc., can solve problems such as low efficiency, poor grinding quality, and potential safety hazards, and achieve automatic adjustment of grinding, convenient and fast use, and satisfactory The effect of using the request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

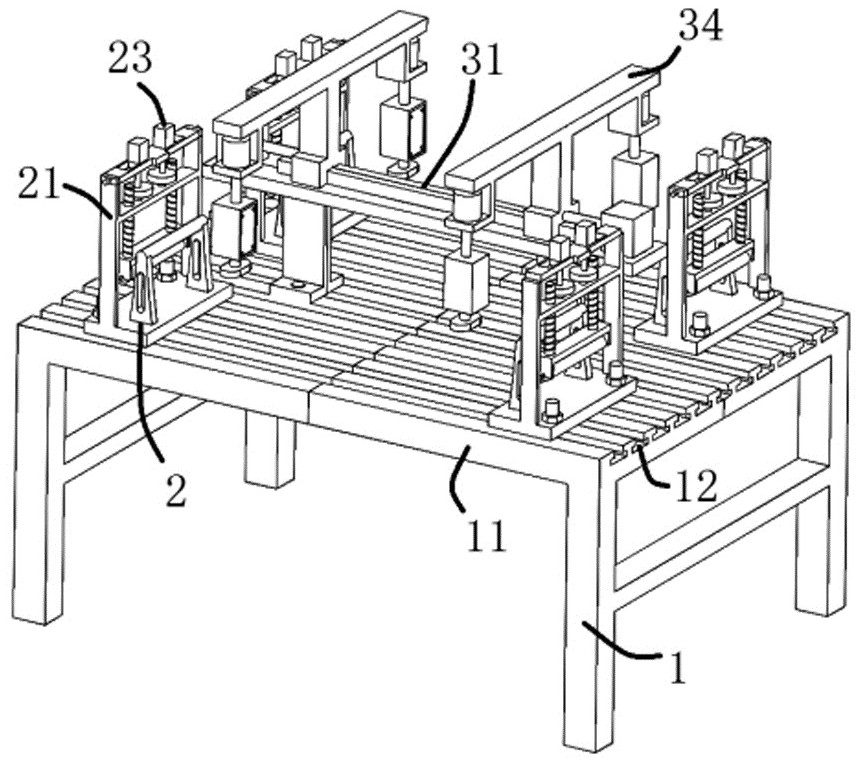

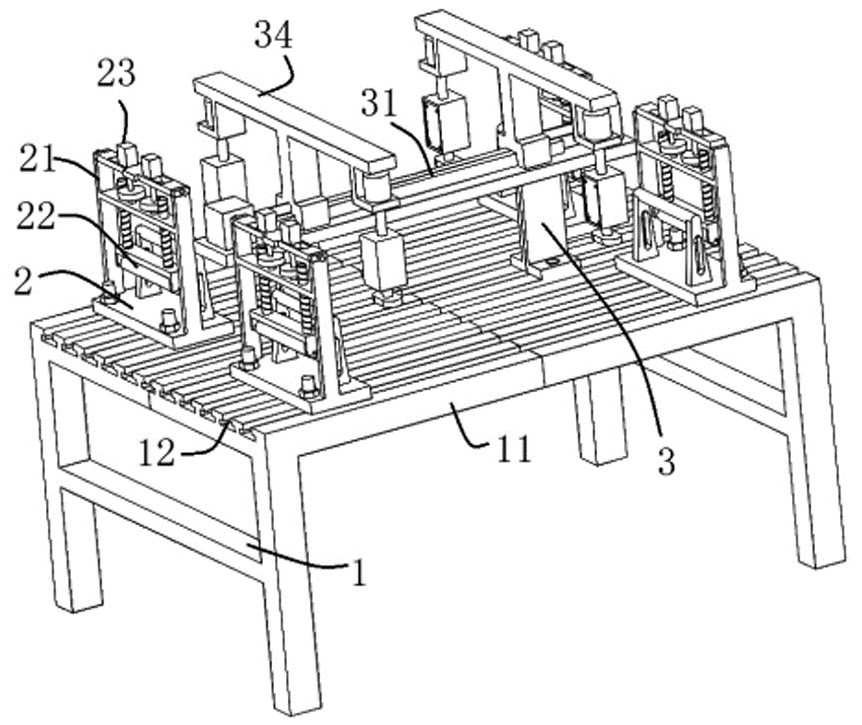

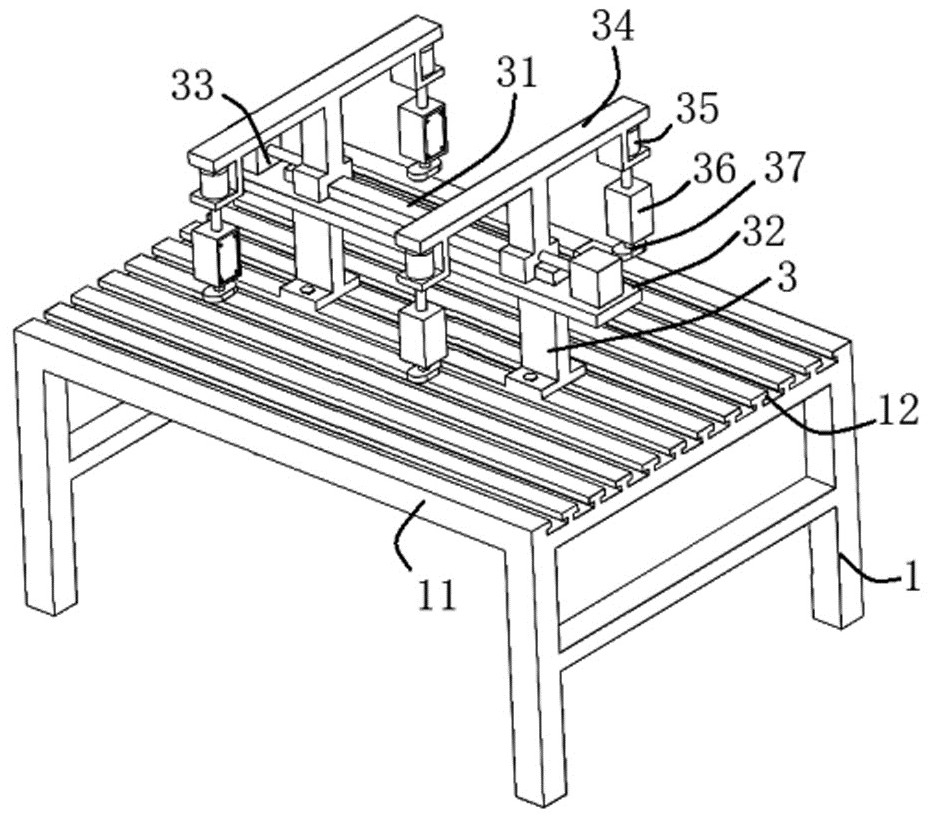

[0030] Example: see Figure 1-5 , an intelligent carbon skateboard grinding machine with supporting auxiliary functions, including a frame 1, four sets of clamping components and a grinding component, wherein the frame 1 is a table-shaped bottom with four legs, and the top plate 11 of the frame 1 Installing grooves 12 are distributed on it; wherein two sets of clamping components are arranged symmetrically along two ends of one length direction of the top plate 11, and the other two sets of clamping components are symmetrically set along two ends of the other length direction of the top plate 11; the clamping components It contains a first compression rod 24 and a second compression rod 22, and the first compression rod 24 and the second compression rod 22 form a clamping gap; the grinding assembly is located in the middle of the top plate 11, and the grinding assembly Contain two sliding frames 34, the two ends of each sliding frame 34 are all equipped with grinding motor, th...

Embodiment 2

[0038] Example 2: see Image 6 , the present embodiment also provides a grinding method for an intelligent carbon skateboard grinding machine with supporting auxiliary function, comprising the following steps:

[0039] Step 1: Connect the grinding motor, lifting electric push rod 35, driving motor 23, and electric push rod 33 to an external power supply through wires, and install a control switch on each wire; insert the curved parts at both ends of the carbon skateboard into the same length of frame 1 The gap between the first compression rod 24 and the second compression rod 22 of the two groups of clamping assemblies on the side;

[0040] Step 2: Turn on the driving motor 23 to drive the worm gear to rotate, so that the installation frame moves downward, and drives the second pressing rod 22 to press the curved part of the carbon skateboard;

[0041] Step 3: Control the lifting electric push rod 35 to extend downward, so that the grinding head 37 is located on the grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com