Anesthetic waste gas extraction device for anesthesia department

A waste gas and departmental technology, which is applied in the direction of dust removal, cleaning methods and utensils, and separation of dispersed particles, can solve problems such as complex structures, and achieve the effect of increasing sterilization time, increasing flow distance, and improving sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

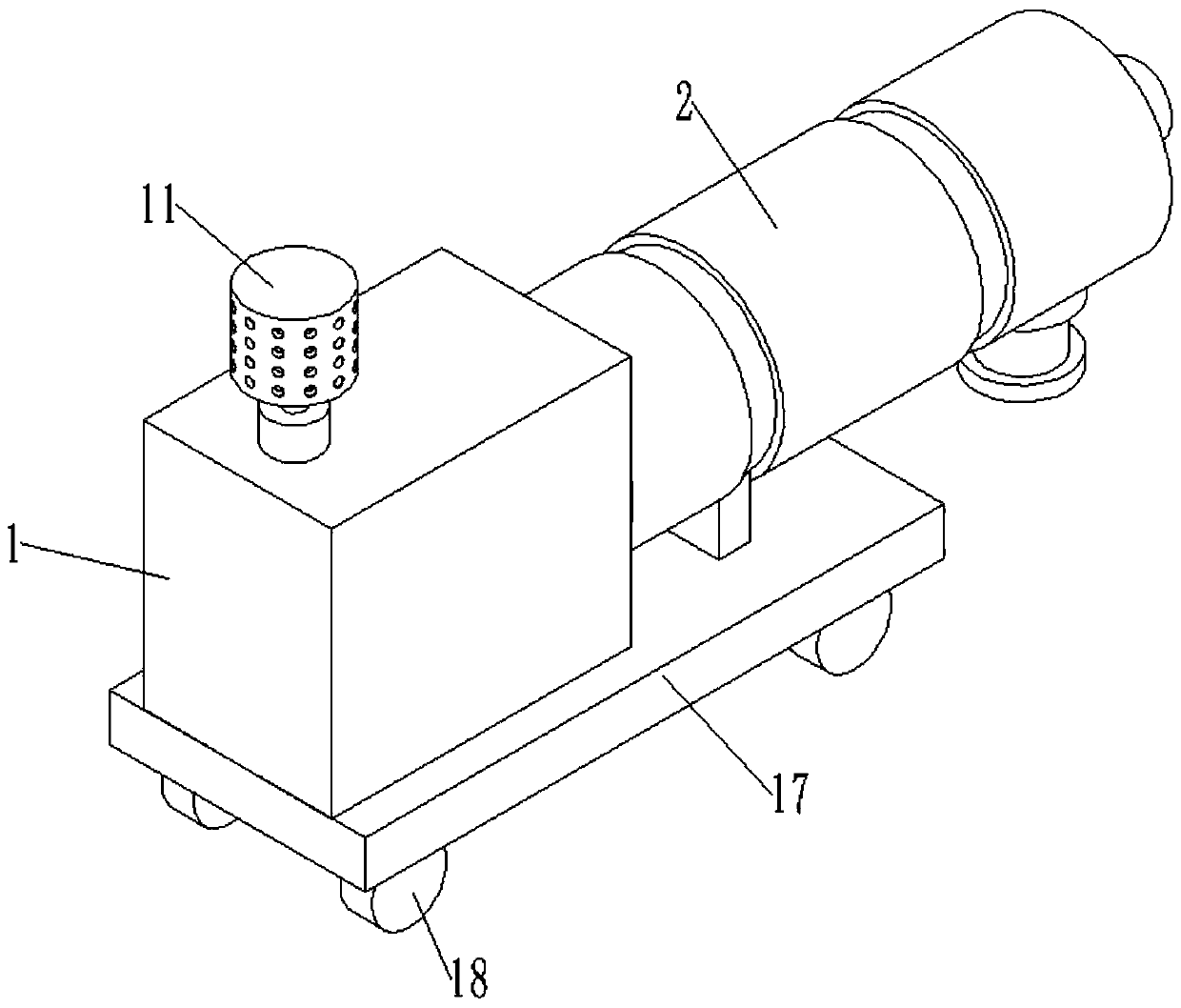

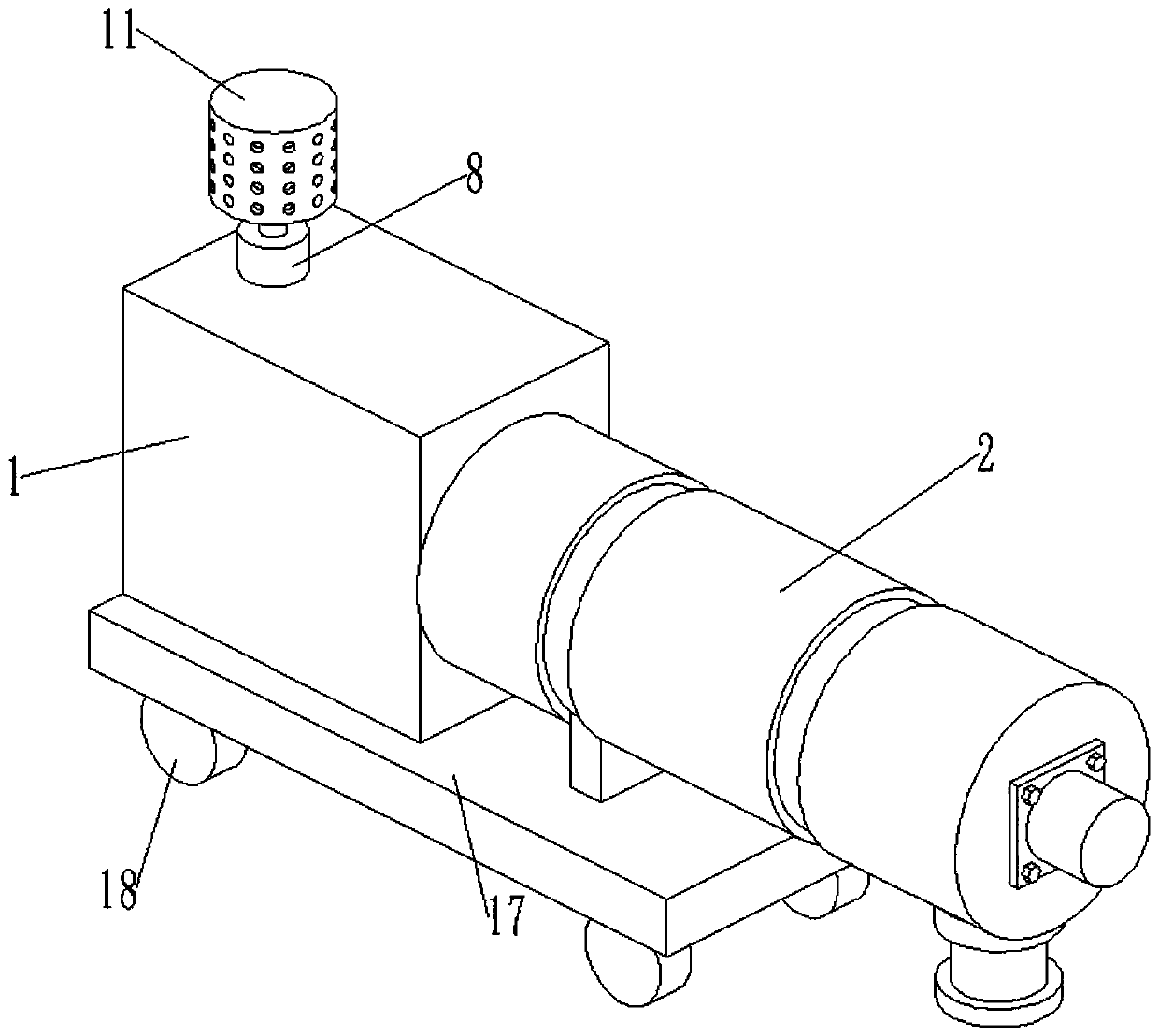

[0028] Such as figure 1 with figure 2 As shown, an anesthesia waste gas extraction device for an anesthesia department includes a purification box 1 and a sterilization cylinder 2. The purification box 1 is used to purify the anesthesia waste gas, and the bacteria removal box is used to sterilize the anesthesia waste gas.

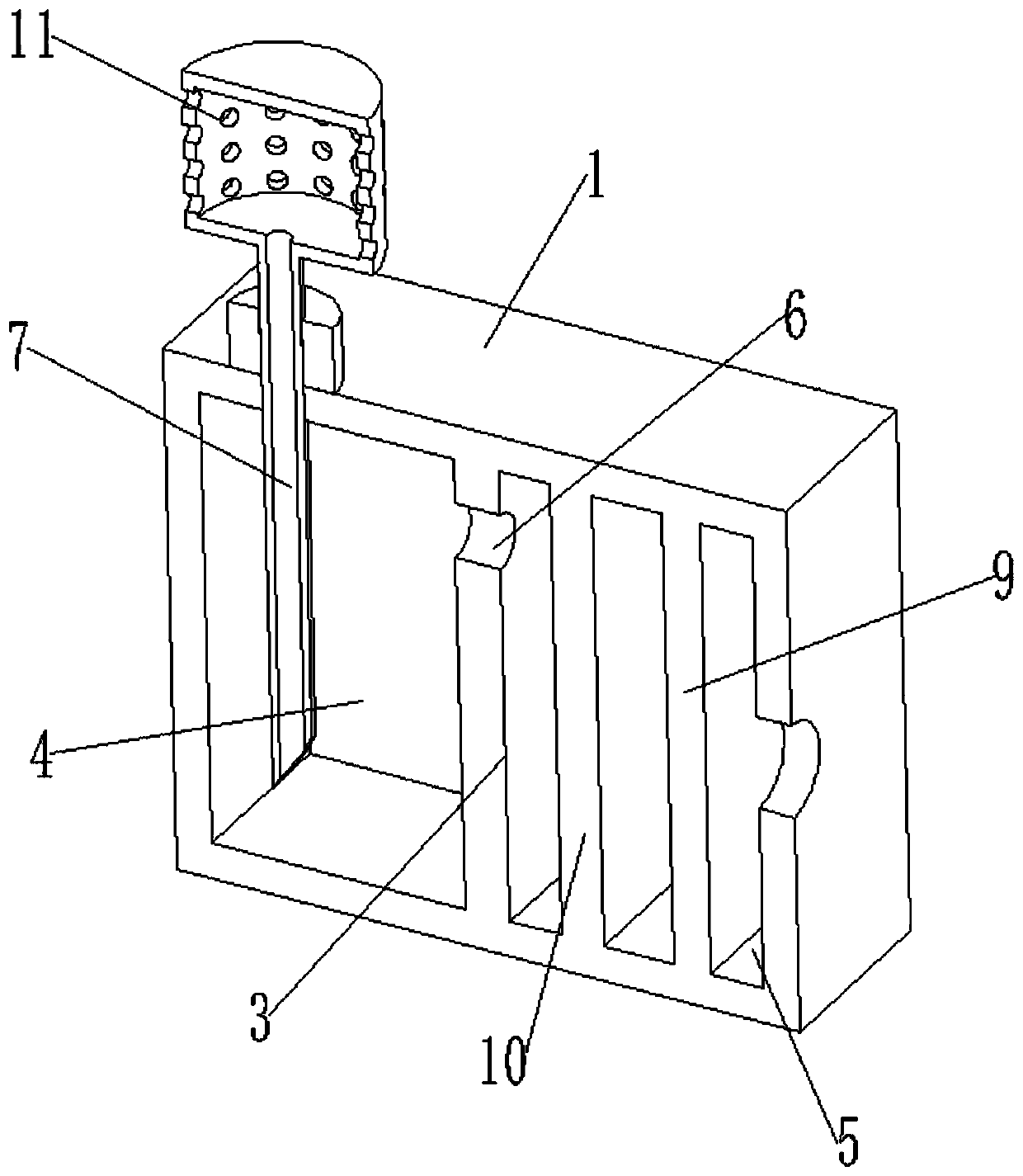

[0029] Such as image 3 with Figure 4 As shown, the purification box 1 is provided with a partition plate 3, and the partition plate 3 divides the inner space of the purification box 1 into a first chamber 4 and a second chamber 5; the partition plate 3 is provided with a communication hole 6, The communication hole 6 communicates with the first chamber 4 and the second chamber 5; the first chamber 4 is provided with sodium hydroxide solution, the purification box 1 is provided with an air inlet pipe 7, and the air inl...

Embodiment 2

[0038] Embodiment 2 is a further improvement on Embodiment 1.

[0039] Such as Figure 5 with Image 6 As shown, deflector 15 and silencer pipe 16 are arranged in the sterilization cylinder 2, and the two ends of silencer pipe 16 are open and coaxially arranged with the sterilization chamber, between the pipe wall of silencer pipe 16 and the inner peripheral wall of the sterilization chamber There are intervals, the pipe wall of the muffler pipe 16 is provided with a plurality of muffler holes, the muffler pipe 16 is spirally wound with a deflector 15, one side of the deflector 15 is located in the muffler pipe 16, and the other side of the deflector 15 It abuts against the inner peripheral wall of the sterilization cavity.

[0040] The setting of the deflector 15 will guide the anesthesia waste gas to form a spiral flow path when it flows in the sterilization chamber. Compared with the traditional straight flow path, it increases the flow path of the anesthesia waste gas an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com