A kind of biodegradable defoamer and preparation method thereof

A biodegradable and defoaming agent technology, applied in the preparation of sugar derivatives, separation methods, sugar derivatives, etc., can solve the problems of low foam breaking efficiency, silicon spots, harsh use conditions, etc., to adapt to the pH range and be environmentally friendly , adapt to a wide range of PH, reduce the effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

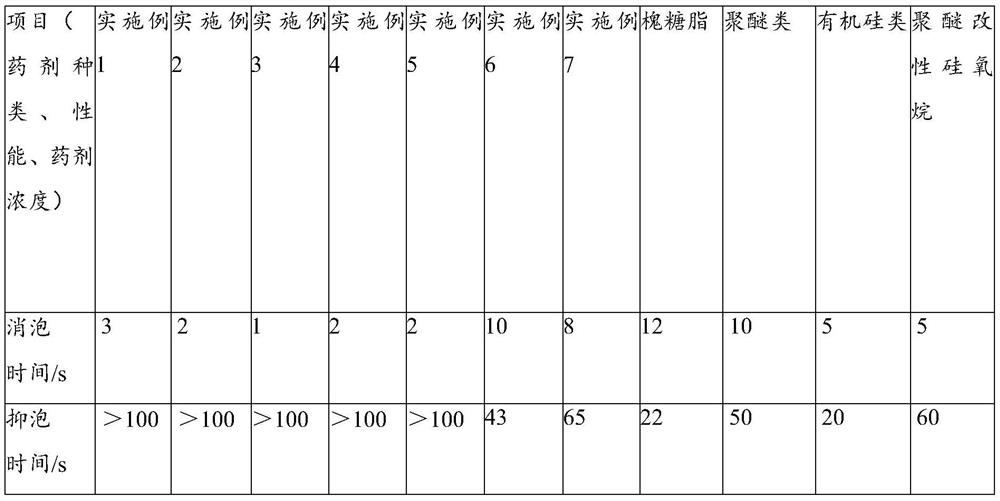

Examples

Embodiment 1

[0025] A method for preparing a biodegradable defoamer, comprising the following steps:

[0026] (1) feed intake: in the autoclave, after putting in water, alkaline catalyst sodium hydroxide, and sophorolipid, the mass ratio of the addition of water and sophorolipid is 24:50, and alkaline catalyst sodium hydroxide and sophorolipid are The mass ratio of the amount of grease added is 0.2:100; first, nitrogen is introduced into the autoclave to replace the air in it, and the replacement operation is repeated 3 times. After the air is completely replaced, a certain amount of ethylene oxide is filled. The molar ratio of ethylene oxide and the amount of microbial fermentation biosurfactant added is 6:1, then fill with nitrogen to the pressure level of 0.4MPa in the autoclave, and then seal the autoclave;

[0027] (2) Heating reaction: in the autoclave, at a temperature of 140 ° C, the reaction is stirred for 2 hours, and a ring-opening polymerization reaction occurs between the soph...

Embodiment 2

[0031] A method for preparing a biodegradable defoamer, comprising the following steps:

[0032] (1) feed intake: in the autoclave, after dropping into water, alkaline catalyst potassium hydroxide, and sophorolipid, the mass ratio of the addition of alkaline catalyst potassium hydroxide and sophorolipid is 0.3:100, and water and sophorolipid are The mass ratio of the added amount of grease is 31:50; first, nitrogen is introduced into the autoclave to replace the air in it, and the replacement operation is repeated 3 times. After the air is completely replaced, a certain amount of ethylene oxide is filled, The molar ratio of ethylene oxide and the amount of sophorolipid added is 8:1, then fill with nitrogen to the pressure in the autoclave to 0.6MPa, and then seal the autoclave;

[0033] (2) Heating reaction: in the autoclave at 160°C, the reaction is stirred for 5h, and the ring-opening polymerization reaction occurs between the sophorolipid and ethylene oxide. After the react...

Embodiment 3

[0037] A method for preparing a biodegradable defoamer, comprising the following steps:

[0038] (1) Feeding: in the autoclave, after putting in water, alkaline catalyst sodium hydroxide and sophorolipid, the mass ratio of the addition of alkaline catalyst sodium hydroxide and sophorolipid is 0.25:100, water and sophorolipid are The mass ratio of the added amount of grease is 27:50; first, nitrogen is introduced into the autoclave to replace the air in it, and the replacement operation is repeated 3 times. After the air is completely replaced, a certain amount of ethylene oxide is charged, The molar ratio of ethylene oxide and the added amount of microbial fermentation biosurfactant is 7:1, then nitrogen is charged to the pressure in the autoclave to 0.5MPa, and then the autoclave is sealed;

[0039] (2) Heating reaction: in the autoclave at a temperature of 150 °C, the reaction is stirred for 3 hours, and a ring-opening polymerization reaction occurs between the sophorolipid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com