Sprayable anti-adhesion material, anti-adhesion tissue sealant and preparation method of anti-adhesion tissue sealant

An anti-adhesion and sealant technology, which is applied in the field of medical materials, can solve the problems of fast degradation of anti-adhesion materials and poor application performance, and achieve the effects of enhancing tissue affinity, enhancing adhesion behavior, and prolonging degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

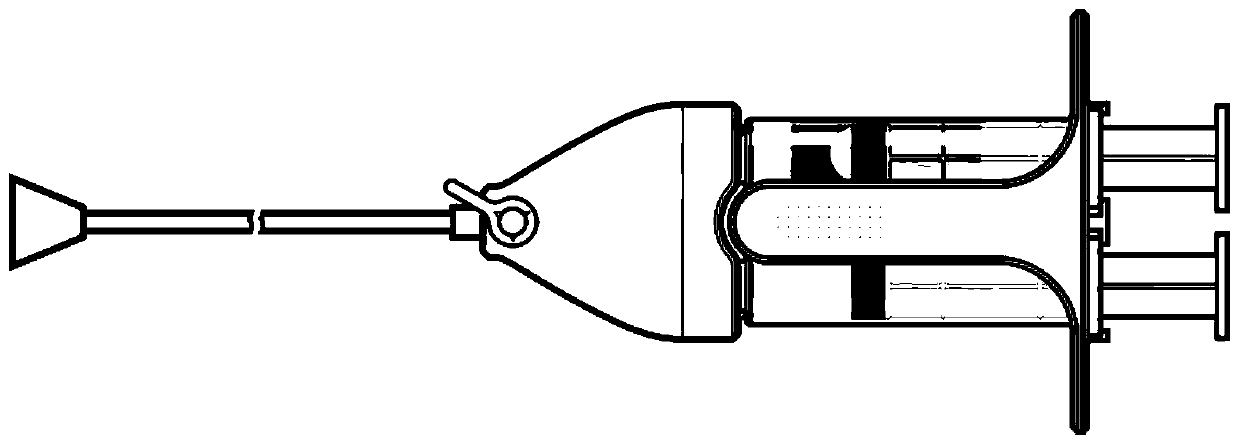

Image

Examples

Embodiment 1

[0065] An anti-adhesion material, the anti-adhesion material includes an effective component A and an effective component B, wherein the effective component A is a slightly cross-linked hyaluronic acid-gelatin copolymer aqueous solution, and the effective component B is a saturated solution of racemic polylactic acid , wherein the micro-crosslinked hyaluronic acid-gelatin copolymer is formed by micro-crosslinking hyaluronic acid and gelatin under the action of a crosslinking agent,

[0066] Wherein the preparation method of micro-crosslinked hyaluronic acid-gelatin copolymer is as follows:

[0067] S1. Measure hyaluronic acid (HA, 1.25g, dissolved in 62.5mL distilled water, pH value is 3.5), gelatin (Gel, 1.25g, dissolved in 12.5mL distilled water) and cross-linking agent carbodiimide ( EDC, 0.5g, dissolved in 5mL distilled water), the ratio is (M HA +M Gel ): M EDC =5:1, M HA :M Gel = 1:1;

[0068] S2. Put 62.5mL of HA aqueous solution in a 500mL Erlenmeyer flask, place...

Embodiment 2

[0077] An anti-adhesion material, the anti-adhesion material includes an effective component A and an effective component B, wherein the effective component A is a micro-crosslinked hyaluronic acid-gelatin copolymer, and the effective component B is a saturated solution of racemic polylactic acid, The micro-crosslinked hyaluronic acid-gelatin copolymer is formed by micro-crosslinking hyaluronic acid and gelatin under the action of a crosslinking agent.

[0078] Wherein the preparation method of micro-crosslinked hyaluronic acid-gelatin copolymer is as follows:

[0079] S1. Measure hyaluronic acid (HA, 1.25g, dissolved in 62.5mL distilled water, pH value is 3.5), gelatin (Gel, 0.42g, dissolved in 4.2mL distilled water) and cross-linking agent carbodiimide ( EDC, 0.167g, dissolved in 3.3mL distilled water), the ratio is (M HA+M Gel ): M EDC =10:1, M HA :M Gel = 3:1;

[0080] S2. Place 62.5mL of HA aqueous solution in a 500mL Erlenmeyer flask, place the Erlenmeyer flask in ...

Embodiment 3

[0089] An anti-adhesion material, the anti-adhesion material includes an effective component A and an effective component B, wherein the effective component A is a micro-crosslinked hyaluronic acid-gelatin copolymer, and the effective component B is a saturated solution of racemic polylactic acid, The micro-crosslinked hyaluronic acid-gelatin copolymer is formed by micro-crosslinking hyaluronic acid and gelatin under the action of a crosslinking agent.

[0090] Wherein the preparation method of micro-crosslinked hyaluronic acid-gelatin copolymer is as follows:

[0091] S1. Measure hyaluronic acid (HA, 2.24g, dissolved in 112.0mL distilled water, pH value is 3.5), gelatin (Gel, 0.56g, dissolved in 4.7mL distilled water) and cross-linking agent carbodiimide ( EDC, 0.2g, dissolved in 4.0mL distilled water), the ratio is (M HA +M Gel ): M EDC =14:1, M HA :M Gel =4:1;

[0092] S2. 112.0mL of HA aqueous solution was placed in a 500mL Erlenmeyer flask, and the Erlenmeyer flask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com