Heat-resistant type vaporizing flue metal corrugated expansion joint

A corrugated expansion joint and vaporization flue technology, which is applied in the field of expansion joints, can solve the problems of insufficient flexibility of metal bellows elastic compensation, large manpower and material resources, troublesome replacement or maintenance, etc., and achieves small structural rigidity and improved use. Long life, reasonable effect of anti-corrosion structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

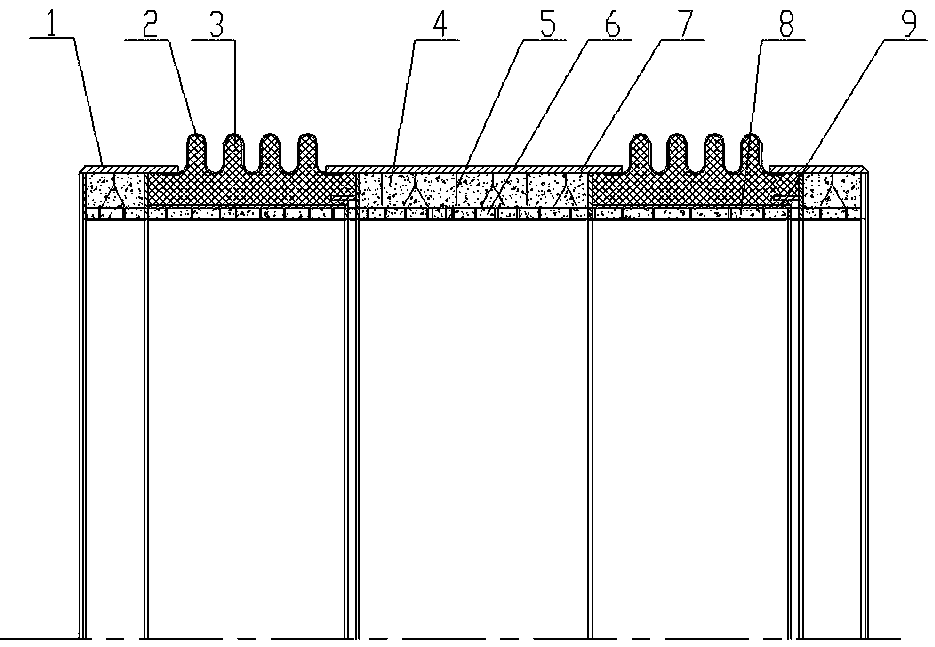

[0018] figure 1 The shown embodiment of heat-resistant vaporization flue metal corrugated expansion joint is a DN4600 super-large product, which includes end pipe 1, bellows 2, filler 3, armor castable layer 4, anchor 5, tortoise shell net 6. Intermediate pipe 7, castable layer 8 and coating 9. Both the end pipe 1 and the middle pipe 7 are thin-walled round pipes of DN4600mm, each end of the middle pipe 7 is sealed and connected to a matching bellows 2, and the outer ports of the two coaxially connected bellows 2 are each sealed and connected to one The end pipe 1 is evenly distributed on the inner walls of the end pipe 1 and the intermediate pipe 7 with anchors 5 protruding radially inward. The anchors 5 are Y-shaped, adjacent anchors 5 are staggered, and the Y-shaped direction is offset by 90°. The anchors 5 arranged in such disloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com