Concentrate lactose solution and preparation method thereof

A lactose liquid, lactose technology, applied in the preparation of sugar derivatives, chemical instruments and methods, disaccharides and other directions, can solve the problems of low yield, high cost, low purity, etc., and achieve low salt, low cost and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

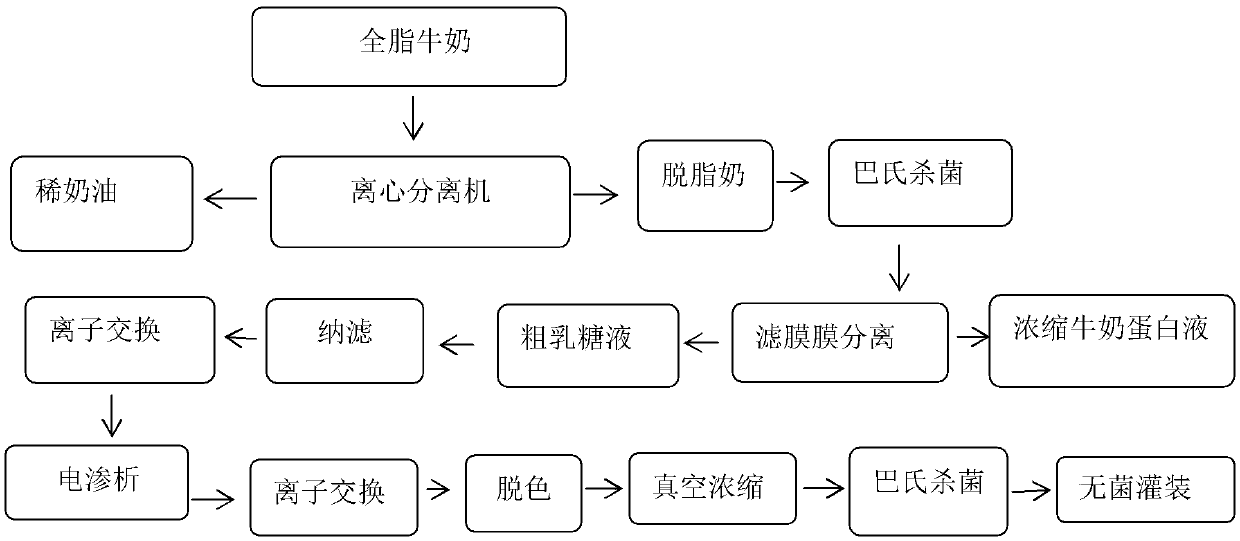

Method used

Image

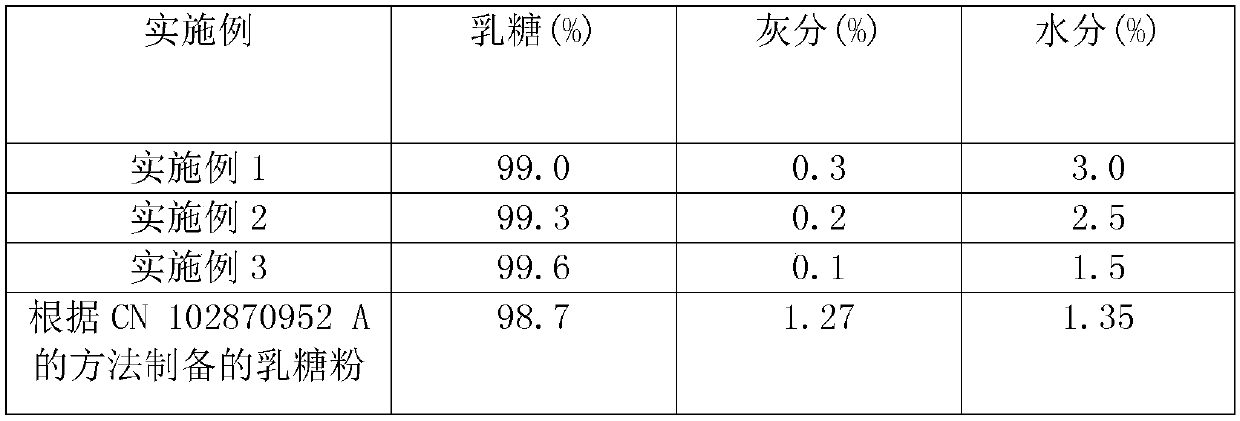

Examples

Embodiment 1

[0047] Example 1 (Preparation of concentrated refined lactose liquid from milk)

[0048] (1) Preparation of skimmed milk: the raw milk is preheated to 50°C, and then separated into skimmed milk and cream with a speed of 5000 rpm through a centrifuge. The skim milk has a fat content of 0.1%. The skimmed milk is pasteurized at 75°C / 15s.

[0049] (2) Preparation of lactose liquid: ultrafiltration of skimmed milk to separate lactose liquid. The ultrafiltration membrane adopts a hollow roll membrane (Drummel roll ultrafiltration membrane DUFE-4040S), and the ultrafiltration membrane has a molecular weight cut-off of 5000 Da. The skimmed milk is ultrafiltered to separate the concentrated milk protein liquid and the lactose liquid, and the total dry matter of the lactose liquid is 6.0%. When skimmed milk enters the membrane at a temperature of 8°C, a pressure of 2.0bar, and a flow rate of 3000L / H, the ultrafiltration membrane flux drops to 10% of the initial membrane flux to stop ultraf...

Embodiment 2

[0058] Example 2 (Preparation of refined lactose liquid from milk)

[0059] (1) Preparation of skimmed milk: the raw milk is preheated to 55°C, and then separated into skimmed milk and cream by a centrifuge at a speed of 5600rpm. The fat content of skimmed milk is 0.05%. The skimmed milk is pasteurized at 70°C 15s.

[0060] (2) Preparation of lactose liquid: skimmed milk ultrafiltration to separate lactose liquid, the ultrafiltration membrane adopts flat membrane (Fometech flat ultrafiltration membrane FMDU-004), and the ultrafiltration membrane has a molecular weight cut-off of 10000Da. The skimmed milk is ultrafiltered to separate the concentrated milk protein liquid and the lactose liquid, and the total dry matter of the lactose liquid is 5.5%. When skimmed milk enters the membrane at a temperature of 10°C, a pressure of 2.5bar, and a flow rate of 3500L / H, the ultrafiltration membrane flux drops to 10% of the initial membrane flux to stop ultrafiltration.

[0061] (3) Concentrat...

Embodiment 3

[0069] Example 3 (Preparation of refined lactose liquid from milk)

[0070] (1) Preparation of skimmed milk: the raw milk is preheated to 60°C, and then separated into skimmed milk and cream by a centrifugal separator at 6000 rpm. The fat content of skimmed milk is 0.03%. The skimmed milk is pasteurized at 72°C / 15s.

[0071] (2) Preparation of lactose liquid: skimmed milk ultrafiltration separates lactose liquid, the ultrafiltration membrane adopts tubular membrane (Qunli innovative T-CUT MBR tubular ultrafiltration membrane), and the ultrafiltration membrane has a molecular weight cut-off of 8000Da. The skimmed milk is ultrafiltered to separate the concentrated milk protein liquid and the lactose liquid, and the total dry matter of the lactose liquid is 6.0%. When skimmed milk enters the membrane at a temperature of 9.0°C, a pressure of 4.0bar, and a flow rate of 4000L / H, the ultrafiltration membrane flux drops to 10% of the initial membrane flux to stop ultrafiltration.

[0072]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com