White spirit pit mud containing esterification liquid, and preparation process and application thereof

A technology for esterification liquid and liquor, applied in the field of winemaking, can solve problems such as unfavorable base wine quality, peculiar smell of base wine, compaction of pit mud, etc., and achieves increasing the content of wine-making functional microorganisms, strong caproic acid-producing ability, and improving porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

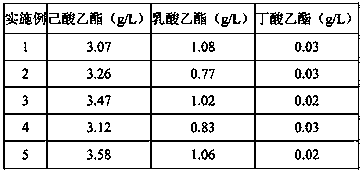

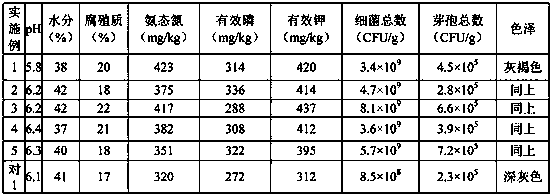

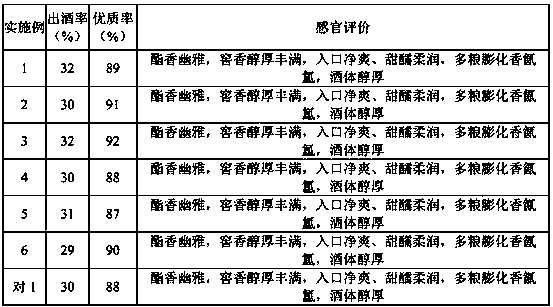

Examples

Embodiment 1

[0032] A liquor cellar mud containing esterification liquid, prepared from the following raw materials:

[0033] Daqu powder 10 kg, bean cake powder 10 kg, wet distiller's grains 60 kg, pit mud 0.1 m 3 , old pit mud 0.05 m 3 , peat 1.5kg, micro-fertilizer 0.4 kg, organic bone 0.3 kg, potassium dihydrogen phosphate 0.9 kg, alcohol 15 kg, caproic acid bacteria third-grade seed liquid 130L, esterification liquid 100 kg, cold boiled water 200 kg and loess 1 m 3 .

[0034] The moisture of said Daqu powder is 9.0-11.0%, the acidity is 0.4-1.2mmol / 10g, the starch is 38-40%, the saccharification power is 700-1000U / g, the liquefaction power is 0.5-1.2U / g, and the fermentation power is 0.5-2.0U / g. g, esterification power 20-30U / g, protease activity 30-70U / g, bacteria (1.0-9.0)×10 7 CFU / g, yeast (1.0-9.0) × 10 5 CFU / g, mold (1.0-9.0) × 10 5 CFU / g, spore (1.0-9.0)×10 7 CFU / g.

[0035] The wet distiller's grains are the distiller's grains after brewing and steaming, and the water co...

Embodiment 2

[0052] A liquor cellar mud containing esterification liquid, prepared from the following raw materials:

[0053] Daqu powder 12 kg, bean cake powder 15 kg, wet distiller's grains 55 kg, pit mud 0.15 m 3 , old pit mud 0.06 m 3 , peat 1 kg, micro-fertilizer 0.2 kg, organic bone 0.6 kg, potassium dihydrogen phosphate 0.5 kg, alcohol 20 kg, caproic acid bacteria third-grade seed liquid 140L, esterification liquid 90 kg, cold boiled water 220 kg and loess 0.8 m 3 .

[0054] The moisture of said Daqu powder is 9.0-11.0%, the acidity is 0.4-1.2mmol / 10g, the starch is 38-40%, the saccharification power is 700-1000U / g, the liquefaction power is 0.5-1.2U / g, and the fermentation power is 0.5-2.0U / g. g, esterification power 20-30U / g, protease activity 30-70U / g, bacteria (1.0-9.0)×10 7 CFU / g, yeast (1.0-9.0) × 10 5 CFU / g, mold (1.0-9.0) × 10 5 CFU / g, spore (1.0-9.0)×10 7 CFU / g.

[0055] The wet distiller's grains are the distiller's grains after brewing and steaming, and the water c...

Embodiment 3

[0072] A liquor cellar mud containing esterification liquid, prepared from the following raw materials:

[0073] Daqu powder 15 kg, bean cake powder 15 kg, wet distiller's grains 65 kg, pit mud 0.12m 3 , old pit mud 0.03 m 3 , peat 1.2kg, micro-fertilizer 0.5 kg, organic bone 0.2 kg, potassium dihydrogen phosphate 0.4 kg, alcohol 20 kg, caproic acid bacteria third-grade seed liquid 150L, esterification liquid 100 kg, cold boiled water 250 kg and loess 1 m 3 .

[0074] The moisture of said Daqu powder is 9.0-11.0%, the acidity is 0.4-1.2mmol / 10g, the starch is 38-40%, the saccharification power is 700-1000U / g, the liquefaction power is 0.5-1.2U / g, and the fermentation power is 0.5-2.0U / g. g, esterification power 20-30U / g, protease activity 30-70U / g, bacteria (1.0-9.0)×10 7 CFU / g, yeast (1.0-9.0) × 10 5 CFU / g, mold (1.0-9.0) × 10 5 CFU / g, spore (1.0-9.0)×10 7 CFU / g.

[0075] The wet distiller's grains are the distiller's grains after brewing and steaming, and the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com