Method for adjusting moisture content of boxed lamina

An adjustment method and technology of moisture content, which are applied to tobacco, tobacco preparation, tobacco processing and other directions, can solve problems such as difficult humidity control, and achieve the effects of shortening alcoholization cycle, improving processing performance, and reducing crushing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

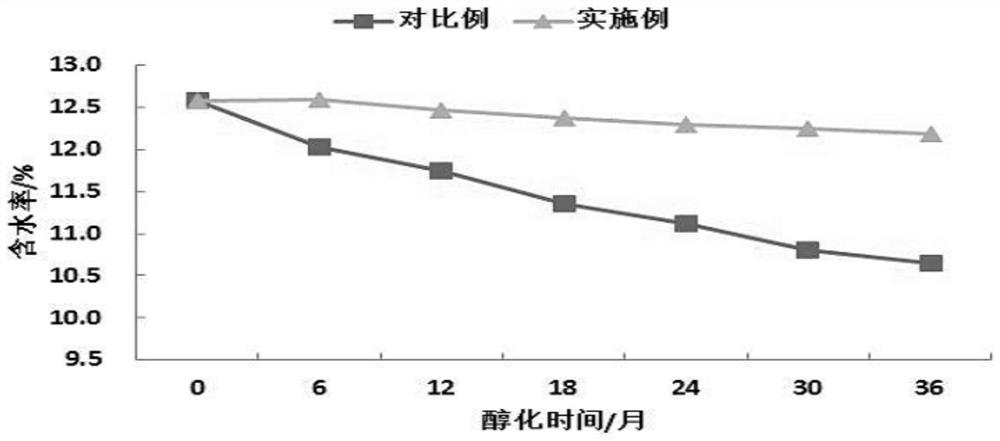

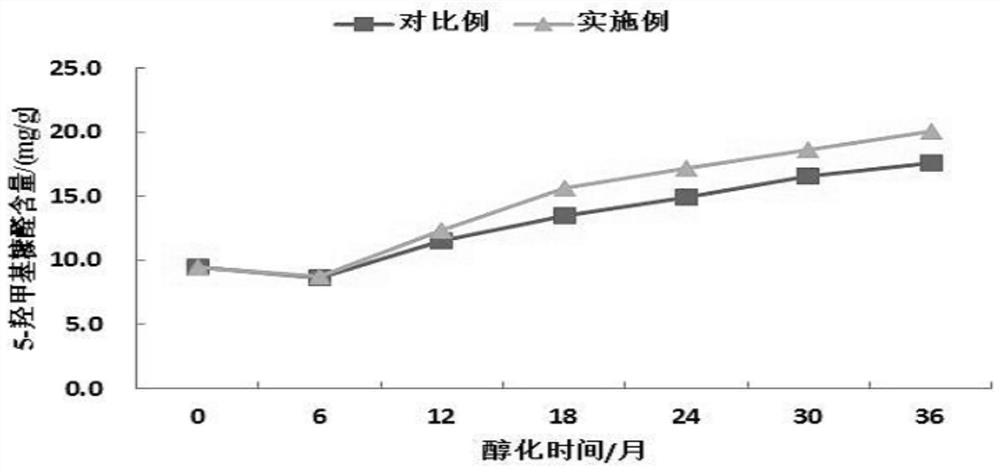

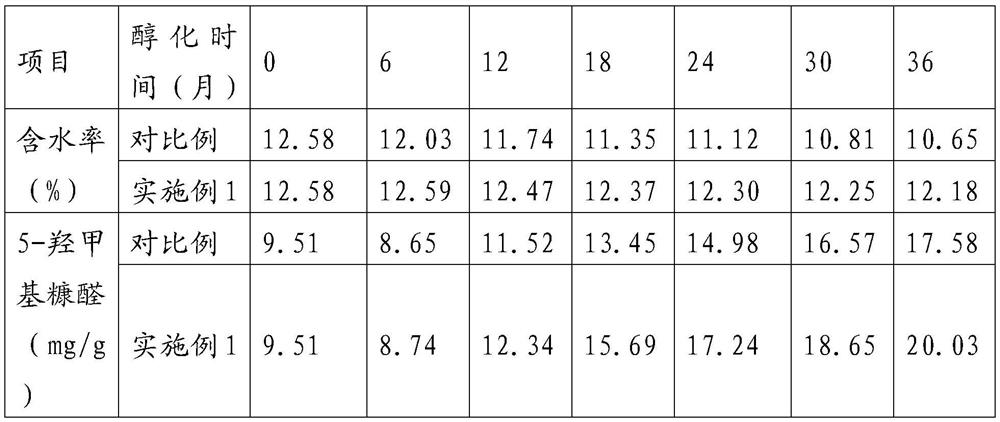

Embodiment 1

[0024] Weigh 15g SiO 2 , 5g Al 2 o 3 (SiO 2 with Al 2 o 3 It is a powder sample, the particle size is 10um, 15um respectively) to 100g mass fraction of 20wt% Ca(OH) 2 The solution was stirred at room temperature for 10 min, then the mixed solution was added into a hydrothermal reaction kettle, and reacted at 200° C. for 15 h. The samples were washed to remove impurities and then vacuum-dried to obtain humidity-regulating materials. Fill the humidity-regulating material into the non-woven fabric after being saturated with water and put it in the center of the box when the cigarettes are packed. The quality of the humidity regulator is 3% of the mass of the cigarettes. Sampling was carried out every 6 months, and the moisture content and 5-hydroxymethylfurfural content of the tobacco were analyzed by multi-point sampling method.

Embodiment 2

[0026] Weigh 10g SiO 2 , 10g Al 2 o 3 (SiO 2 with Al 2 o 3 It is a powder sample, the particle size is 10um, 15um respectively) to 100g mass fraction of 20wt% Ca(OH) 2 The solution was stirred at room temperature for 10 min, then the mixed solution was added into a hydrothermal reaction kettle, and reacted at 200° C. for 15 h. The samples were washed to remove impurities and then vacuum-dried to obtain humidity-regulating materials. Fill the humidity regulating material into the non-woven fabric after being saturated with water and put it in the center of the box when the cigarettes are packed. The quality of the humidity regulator is 3% of the weight of the cigarettes. Sampling was carried out every 6 months, and the moisture content and 5-hydroxymethylfurfural content of the tobacco were analyzed by multi-point sampling method.

Embodiment 3

[0028] Weigh 5g SiO 2 , 7g Al 2 o 3 (SiO 2 with Al 2 o 3 It is a powder sample, the particle size is 10um, 15um respectively) to 100g mass fraction of 20wt% Ca(OH) 2 The solution was stirred at room temperature for 10 min, then the mixed solution was added into a hydrothermal reaction kettle, and reacted at 200° C. for 15 h. The samples were washed to remove impurities and then vacuum-dried to obtain humidity-regulating materials. Fill the humidity-regulating material into the non-woven fabric after being saturated with water and put it in the center of the box when the cigarettes are packed. The quality of the humidity regulator is 3% of the mass of the cigarettes. Sampling was carried out every 6 months, and the moisture content and 5-hydroxymethylfurfural content of the tobacco were analyzed by multi-point sampling method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com