Poly(3-hydroxypropionate-b-lactate) block copolymer using microorganisms

A hydroxypropionate, block copolymer technology, applied in the directions of microorganisms, introduction of foreign genetic material using carriers, biochemical equipment and methods, etc., can solve problems such as poor brittleness and poor physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1. Preparation of recombinant carrier for the preparation of 3-hydroxypropionate-lactate block copolymer

[0081] All DNA cloning experiments were performed according to standard methods (see J. Sambrook, E.F. Fritsch, T. Maniatis, Molecular Cloning. A laboratory Manual, 2 nd ED. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, New York, 1989).

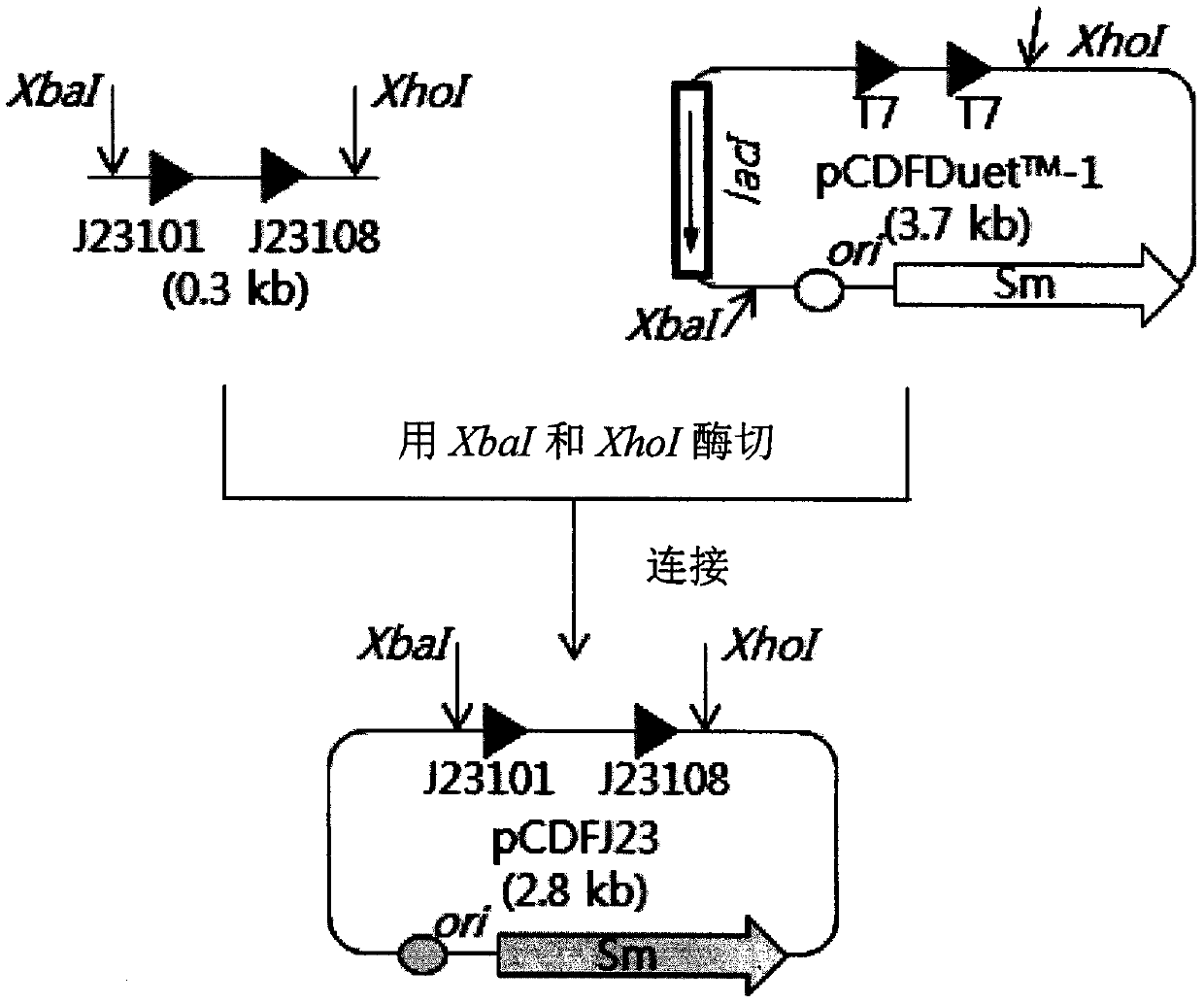

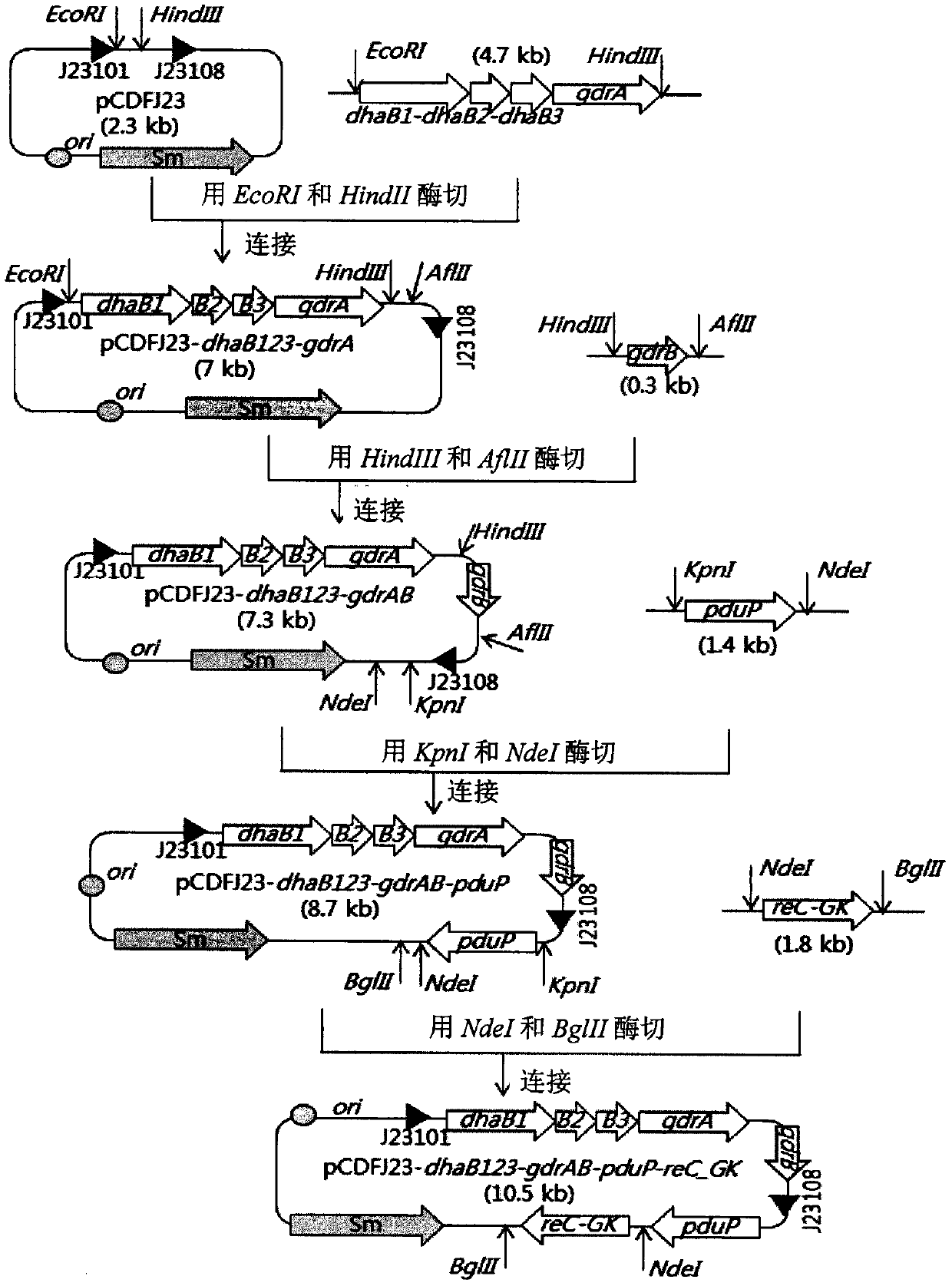

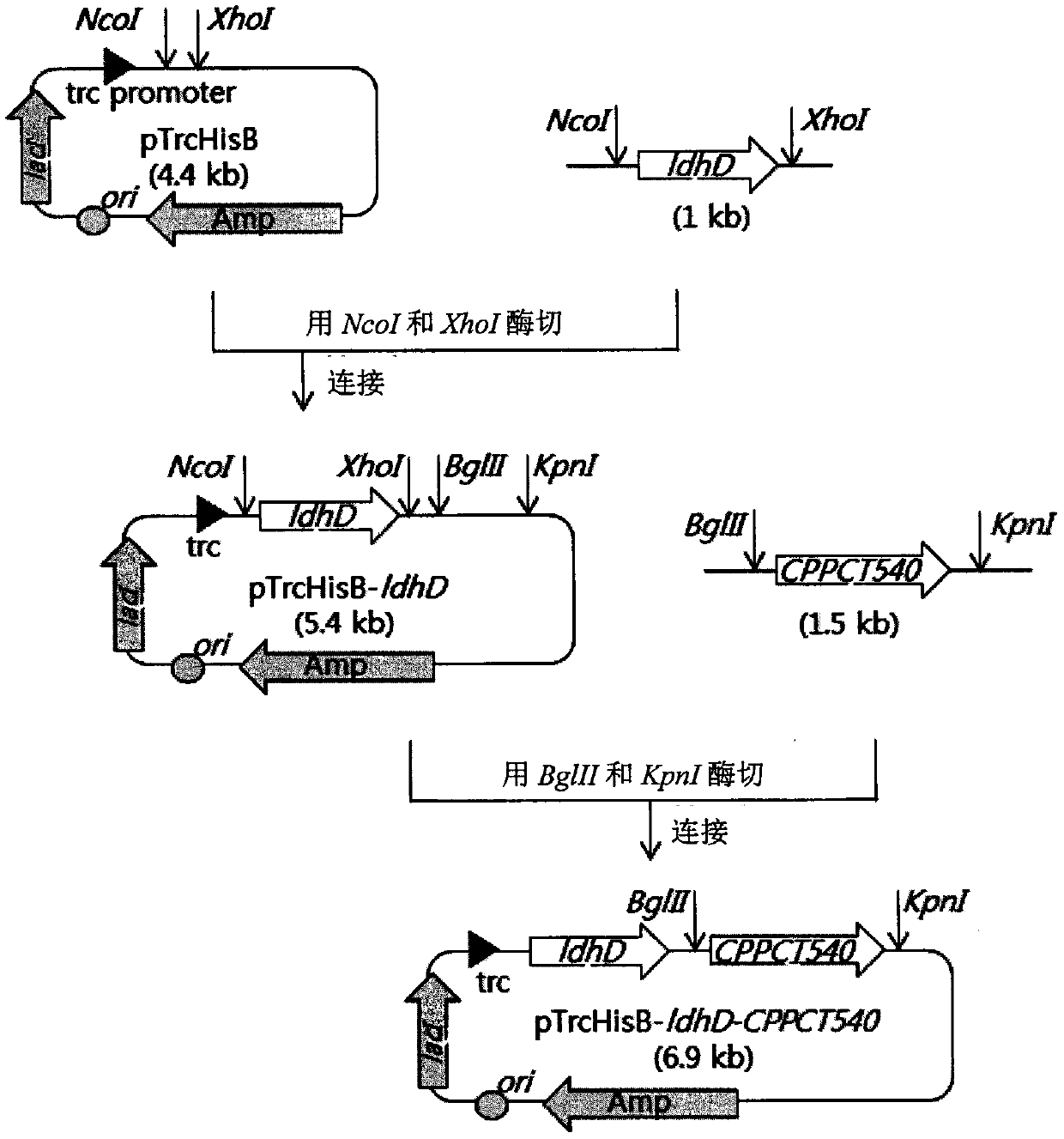

[0082] 1-1. Preparation of pCDFJ23-dhaB123-gdrAB-pduP-reC GK recombinant vector

[0083] pCDFduet TM -1 (Novagen, USA, 3.7 kb) contains two T7 promoters whose expression is induced by IPTG. In this experiment, it was deleted and two constantly expressed promoters were inserted. Digest pCDFduet with XbaI / XhoI TM -1, and a DNA fragment containing the sequences of the constantly expressed J23101 (SEQ ID NO: 19) and J23108 promoter (SEQ ID NO: 20) was inserted into the XbaI / XhoI recognition site. The size of the inserted DNA fragment (promoter) containing the sequences of the J23101 and J23108 promoters wa...

Embodiment 2

[0092] Example 2. Preparation of recombinant bacterial strains for the preparation of 3-hydroxypropionate-lactate block copolymer

[0093] 2.1. Preparation of ldhA gene knockout variants

[0094] In order to prepare lactate-free polymers based on E. coli XL1-Blue (Stratagene, USA), the D-lactate dehydrogenase gene from E. coli XL1-blue involved in the production of lactate during the metabolism of E. coli (ldhA; fermentative D-lactate dehydrogenase, NAD-dependent [Escherichia coli strain K-12 substrain] gene accession number: NC_000913.3, enzyme accession number: EC_1.1.1.28) was knocked out from genomic DNA to prepare E. coli variant, E. coli XL1-Blue ([Delta]ldhA) with deletion of ldhA was prepared. Gene deletions were performed using the red recombination method known in the art. The oligomer for deleting ldhA was synthesized from the base sequences of SEQ ID NO: 36 (5'-atcagcgtacccgtgatgctaacttctctctggaaggtctgaccggctttaattaaccctcactaaagggcg-3') and SEQ ID NO: 37 (5'-...

Embodiment 3

[0097] Example 3. Preparation of 3-hydroxypropionate-lactate block copolymer induced by IPTG

[0098] The recombinant strain prepared in Example 2.2 was cultured in two steps as follows to obtain a 3-hydroxypropionate-lactate block copolymer.

[0099] First, for the first step of cultivation, the transformed recombinant Escherichia coli prepared in Example 2.2 was inoculated into a mixture containing 100 mg / L of ampicillin, 25 mg / L of streptomycin, 20 g / L of glycerol, 0.5 mM of In 100ml MR medium of vitamin B12 and 10mg / L thiamine (every 1L medium contains KH 2 PO 4 6.67g, (NH 4 ) 2 HPO 4 4g, MgSO 4 ·7H 2 0.8g, citric acid 0.8g and trace metal solution 5mL; Wherein, every 1L described trace metal solution comprises 5M HCl 5mL, FeSO 4 ·7H 2 O 10g, CaCl 2 2g, ZnSO 4 ·7H 2 O 2.2g, MnSO 4 4H 2 O 0.5g, CuSO 4 ·5H 2 O 1g, (NH 4 ) 6 Mo 7 o 2 4H 2 O 0.1g, Na 2 B 4 o 2 10H 2 (0.02 g), and cultured while stirring at 30° C. and 250 rpm.

[0100] After 1 day ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com