Preparation method of ordered porous nerve conduit material

A nerve conduit and composite material technology, applied in the field of nerve conduit materials, can solve problems such as uneven mechanical strength, compactness, impact on catheter implantation and surgery, and achieve good biocompatibility, enhanced mechanical properties, and cross-linking conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, preparing a nerve guide material, comprises the following steps:

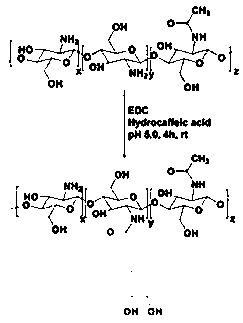

[0032] The first step: synthesis of catechol-modified chitosan,

[0033] At room temperature, dissolve 0.5 g chitosan (CHI) in 100 mL of 0.05 mol / L HCl solution and stir overnight to obtain a 1 wt.% CHI solution; add 0.1 mol / L NaOH solution dropwise to CHI In the solution, adjust the pH of the solution to 4.5, then add 0.4g 3,4-dihydroxyphenylpropionic acid (catechol, HCA) to the solution, and stir until it becomes clear to obtain solution A; at the same time, add 0.48g 1-ethyl -(3-Dimethylaminopropyl)carbodiimide hydrochloride (EDC) was dissolved in 50 mL of 50vol.% ethanol solution to obtain solution B, and solution B was added dropwise to solution A, at 30 React at ℃ for 12 hours. After the reaction, dialyze the reaction solution in a pH=5.0 HCl solution containing NaCl (1wt.%) for 48 hours, change the dialysate every 12 hours, and then dialyze in deionized water for 24 hours , the rea...

Embodiment 2

[0039] Example 2, using the nerve guide material prepared above for cell migration:

[0040] Soak the nerve guide material in 75vol.% ethanol, irradiate with ultraviolet light for 30 minutes to disinfect, then wash with PBS solution 3 times to remove ethanol, soak the obtained nerve guide material in PC12 basal medium, and make the medium submerge the nerve guide 2 / 3 of the material height, add 20 μL containing 10 5 PC12 cell fluid, placed in 5% CO 2 The concentrations were cultured in a 37°C incubator for 3 hours, 6 hours, 12 hours and 24 hours to observe the cell proliferation and migration, such as Figure 7 , is the value-added and migration fluorescence map of PC12 cells on the ordered porous nerve guide material at different times (3 hours, 6 hours, 12 hours and 24 hours). The results show that PC12 cells can migrate from the top to the bottom of the nerve guide material, and can Proliferate effectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com