Separation method of mold material with glass-transition temperature

A glass transition and separation method technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low LED package yield, deformation of LED package, bulging of the middle part, etc., to achieve high cutting Separation yield, no quality loss, right size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

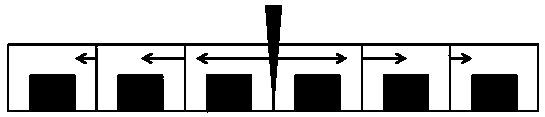

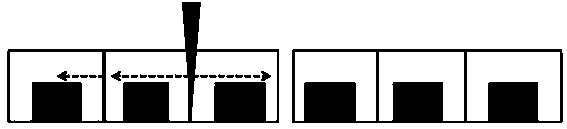

[0036] This embodiment has the separation method of the mold material of glass transition temperature, in this embodiment, the mold material with glass transition temperature is an LED light source with a transparent or translucent layer, such as Figure 8 As shown, the LED light source in the LED light source array includes an LED chip body and a silicone encapsulation layer covering the top and side surfaces of the LED chip body. The separation method includes:

[0037] Step 1: Film expansion process: first, heat and keep warm the uncut LED light source semi-finished substrate. The uncut LED light source semi-finished substrate includes a number of chips distributed in an array, and the package that is packaged with the chips distributed in the array as a whole layer; the heating and holding temperature range in the film expansion process meets the following conditions:

[0038] (1) The modulus of the encapsulation layer changes with its own temperature as a function expressio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com