Steel bar size detection system and method based on image processing

An image processing and size detection technology, applied in the field of image processing, can solve the problems of bad interference, complex and redundant methods, and high equipment requirements, and achieve the effect of improving accuracy, accurate size recognition and positioning, and clear edges and contours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

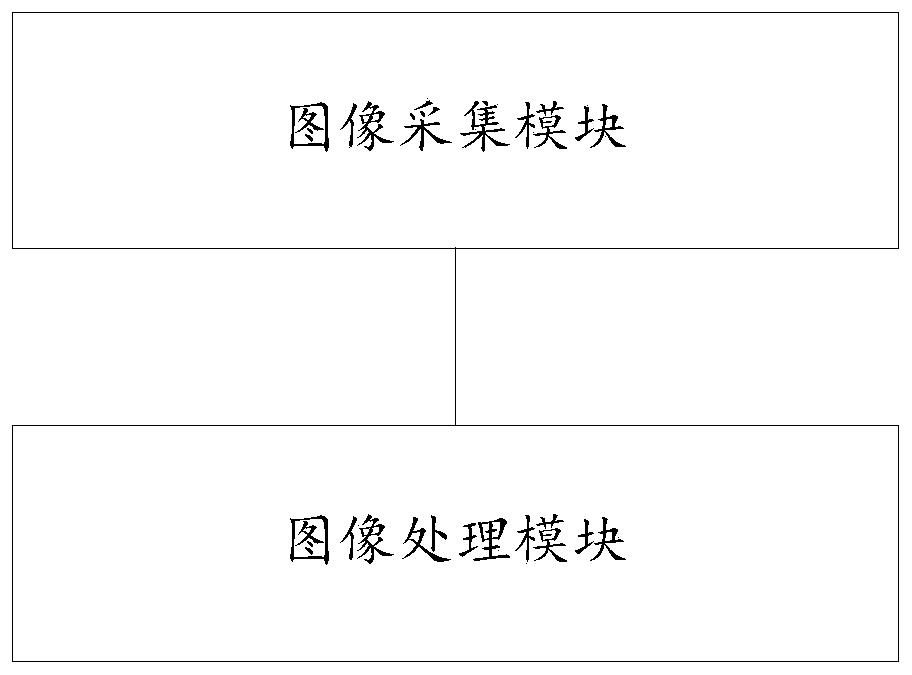

[0053] figure 1 A schematic structural diagram of a steel bar size detection system based on image processing in this embodiment is given.

[0054] The specific structure of the steel bar size detection system based on image processing in this embodiment will be described in detail below in conjunction with the accompanying drawings.

[0055] Such as figure 1 As shown, the steel bar size detection system based on image processing of the present embodiment includes:

[0056] (1) The image acquisition module, which is carried on the unmanned aerial vehicle, is configured to collect pictures of the construction site.

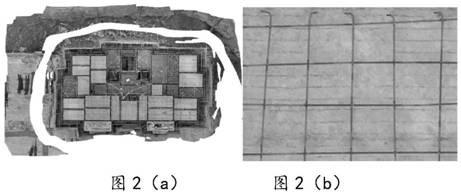

[0057]In a specific implementation, the image acquisition module can be realized by using a camera. Figure 2(a) is the collected panorama of the construction site. Figure 2(b) shows the extracted single-layer steel bar image to be detected.

[0058] (2) image processing module, which is configured to:

[0059] a. Detect the edge of the steel bar in the constr...

Embodiment 2

[0084] The present embodiment provides a method for detecting steel bar size based on image processing, which includes:

[0085] Step 1: Receive the construction site pictures collected by the image acquisition module carried by the drone;

[0086] In a specific implementation, the image acquisition module can be realized by using a camera.

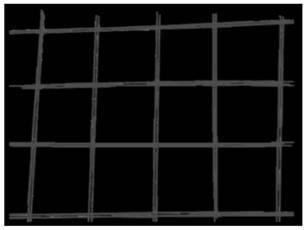

[0087] Step 2: Detect the edge of the steel bar in the construction site picture, and extract the edge binary image;

[0088] In the specific implementation, the Sobel edge detection algorithm of direct convolution is used to detect the edge of the steel bar in the construction site picture, and the edge binary image is extracted.

[0089] The advantage of the above technical solution is that the color of the steel bar is very close to the shading background, and there are bad interference and other noises. It is necessary to use a specific edge detection algorithm combined with the Hough straight line to effectively extract the edge. Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com