Method for adjusting temperature curve of kiln system by utilizing temperature brick

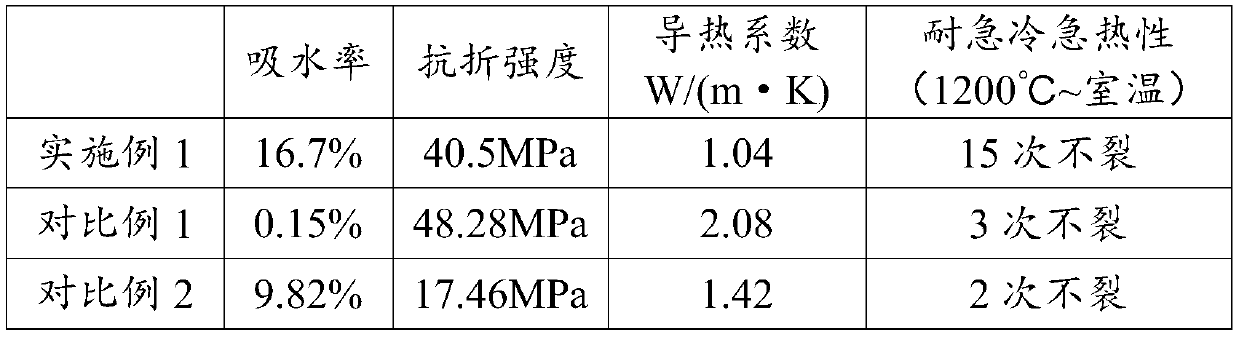

A technology of system temperature and temperature, applied in the field of ceramic tile kilns, can solve the problems of unfavorable stability of the kiln system, short service life, easy breakage, etc., and achieve the effects of simple and practical adjustment means, improving water absorption rate and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Correspondingly, the present invention also discloses a preparation method for the above-mentioned heated brick, which includes:

[0058] (1) Mix 5-10 parts of roller bar waste, 10-25 parts of magnesia soil, 10-20 parts of bentonite, and 5-15 parts of potassium sodium sand to obtain the first mixture;

[0059] The particle size of roller bar waste and potassium sodium sand is relatively large (>3cm); magnesia soil and bentonite contain some larger soil and / or mud lumps; therefore, these components are firstly mixed and ball milled to promote crushing efficiency. ,

[0060] (2) Mix 1-5 parts of polished brick waste residue, 30-40 parts of fly ash, and 0.5-1.5 parts of binder to obtain a second mixture;

[0061] Polished brick waste slag is the waste slag produced during the polishing process of polished bricks, and its particle size is very small, below 200 mesh (74 μm); fly ash is a product of coal combustion, and its particle size is also small, generally 150 mesh (1...

Embodiment 1

[0082] Embodiment 1 with warm brick

[0083] The present embodiment provides a kind of warm brick that is used for porcelain brick kiln, and its formula is:

[0084] 7 parts of roller bar waste, 23 parts of magnesia soil, 17 parts of bentonite, 4 parts of polished brick waste residue, 36 parts of fly ash, 13 parts of potassium sodium sand; 1 part of sodium carboxymethyl cellulose;

[0085] Among them, the Al 2 o 3 The content is 58.6wt%; the content of MgO in magnesia soil is 23.2wt%, SiO 2 The content is 65.9wt%, Al 2 o 3 The content of Al in fly ash is 1.6wt%; 2 o 3 The CaO content is 31.7 wt%, and the CaO content is 12.4 wt%.

[0086] The preparation method is the same as in Example 2.

Embodiment 2

[0094] Example 2 Using warm bricks to adjust the temperature curve of the kiln system

[0095] This embodiment discloses a method for adjusting the temperature curve of the kiln system by using heated bricks, including:

[0096] (1) Soak the warm brick of Example 1 in water for 2 minutes and then pull it out and drain it;

[0097] (2) close the first valve and the second valve; the opening degree of the third valve is increased to 80%, and the opening degree of the fourth valve is increased to 90%;

[0098] (3) Put the drained heated bricks into the conveying device and send them into the firing kiln;

[0099] (4) After the warm brick enters the kiln for 8 minutes, increase the opening of the first valve to 40%, reduce the opening of the third valve to 15%, and increase the opening of the fifth valve to 70%.

[0100] (5) After entering the kiln with warm bricks for 40 minutes, increase the opening of the second valve to 40%; reduce the opening of the fourth valve to 25%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Average thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com