A kind of anti-ultraviolet cotton fabric and preparation method thereof

A cotton fabric and anti-ultraviolet technology, which is applied in the field of textile fabric processing, can solve the problems of cotton fabric wrinkling and shrinkage, health hazards, and lack of anti-ultraviolet in cotton fabrics, and achieves increased wash fastness, reduced pollution, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

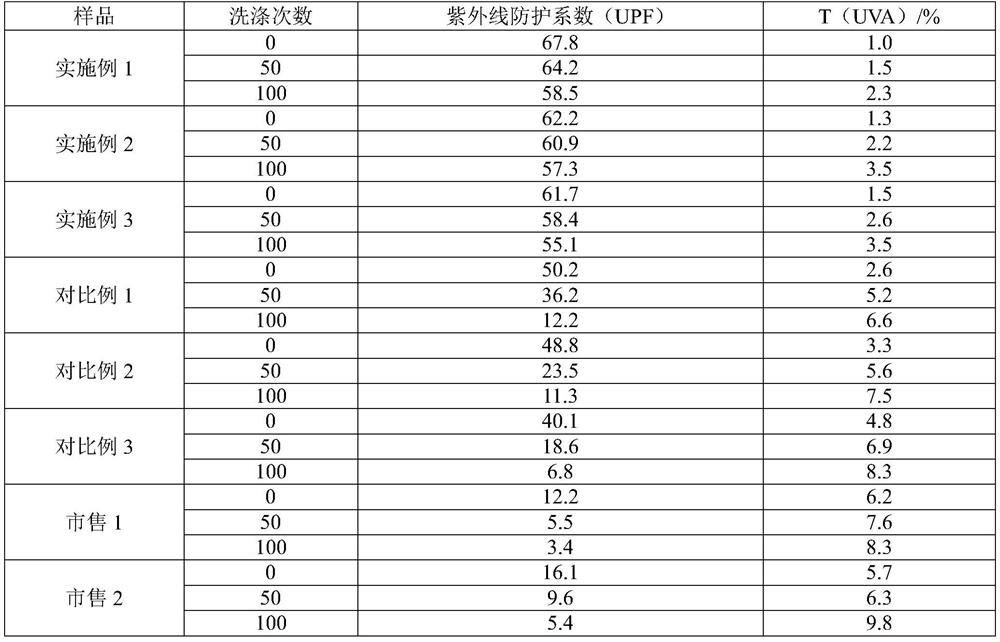

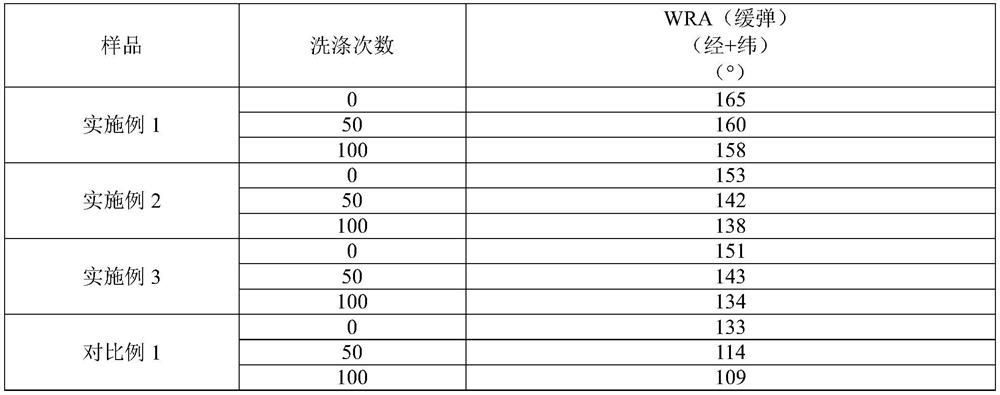

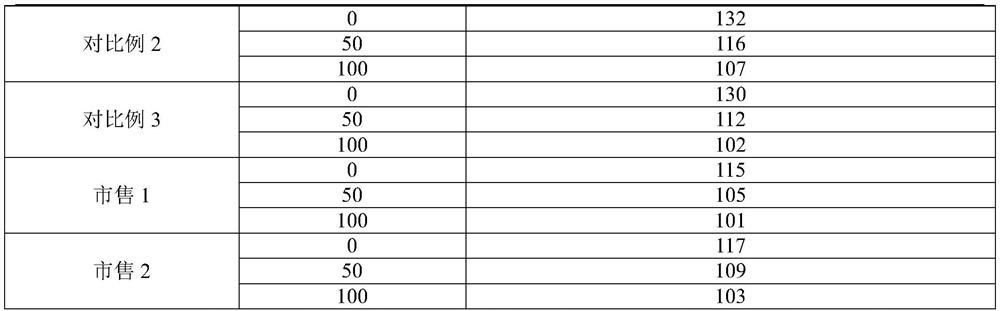

Examples

Embodiment 1

[0022] 1. Cotton fabric pretreatment: put 1g of cotton fabric into 50mL of amylase with a specific activity of 125U / g and a concentration of 40g / L, fully soak it at 60°C for 25min, then wash and dry it with water, and then perform plasma treatment under the following conditions: : The gas is ammonia gas, the processing power is 300W, the pressure is 60Pa, and the processing time is 20min;

[0023] 2. Add 25g whole Daphne neroli plant into 175mL liquid nitrogen, crush it mechanically, add it into 100mL PBS solution containing 1.5g Tween 80, extract at 4°C for 48 hours to obtain Daphne neroli juice, then add 2.5g coenzyme A mixing and stirring to obtain a reaction impregnation solution;

[0024] 3. Take 1 g of the cotton fabric treated in step 1 and add it into 60 mL of reaction impregnation solution to fully impregnate it. The impregnation temperature is 18° C. and the impregnation time is 60 hours. After washing with water, dry at 110° C. to obtain an anti-ultraviolet cotton ...

Embodiment 2

[0026] 1. Cotton fabric pretreatment: put 1g of cotton fabric into 40mL of amylase with a specific activity of 100U / g and a concentration of 30g / L, fully soak it at 50°C for 20min, then wash and dry it with water, and then perform plasma treatment under the following conditions: : The gas is ammonia gas, the processing power is 250W, the pressure is 50Pa, and the processing time is 15min;

[0027] 2. Add 20g of daphne neroli plant to 120mL liquid nitrogen, grind it mechanically, add it to 100mL of PBS solution containing 1.0g Tween 80, extract at 4°C for 24 hours to obtain daphne neroli juice, then add 2.0g of coenzyme A mixing and stirring to obtain a reaction impregnation solution;

[0028] 3. Take 1 g of the cotton fabric treated in step 1 and add it into 50 mL of reaction impregnation solution to fully impregnate it. The impregnation temperature is 10° C. and the impregnation time is 48 hours. After washing with water, dry at 100°C to obtain an anti-ultraviolet cotton fab...

Embodiment 3

[0030] 1. Cotton fabric pretreatment: put 1g of cotton fabric into 60mL of amylase with a specific activity of 150U / g and a concentration of 50g / L, fully soak it at 70°C for 30min, then wash and dry it with water, and then perform plasma treatment under the following conditions: : The gas is ammonia gas, the processing power is 350W, the pressure is 70Pa, and the processing time is 30min;

[0031] 2. Add 30g of daphne neroli plant to 240mL liquid nitrogen, crush it mechanically, add it to 100mL of PBS solution containing 2.0g Tween 80, and extract it at 4°C for 72 hours to obtain daphne neroli juice, then add 3.0g of coenzyme A mixing and stirring to obtain a reaction impregnation solution;

[0032] 3. Take 1 g of the cotton fabric treated in step 1 and add it into 70 mL of reaction impregnation solution to fully impregnate it. The impregnation temperature is 25° C. and the impregnation time is 72 hours. After washing with water, dry at 120°C to obtain an anti-ultraviolet cot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com