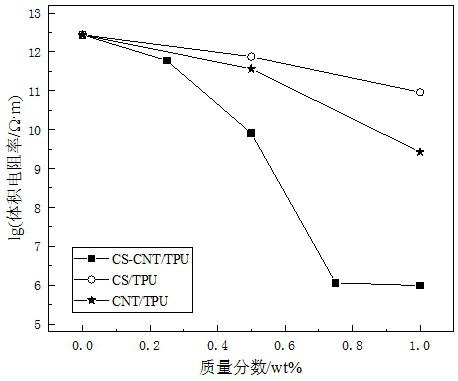

A kind of preparation method of electrical and thermal conductivity functionalized carbon nanotube/tpu composite material

A carbon nanotube, electrical and thermal conductivity technology, which is applied in the field of polymer composite material synthesis, can solve the problems of rising cost of material selection, large dosage, inability to improve the performance of composite materials, etc., and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] 1) Preparation of functionalized carbon nanotubes: add 0.5g carbon nanotubes to 75mL 2mol / L H 2 SO 4 and 75mL4mol / L HNO 3 In the mixed solution, condense and reflux in an oil bath at 110°C, stir magnetically at 500rpm for 10h, and after cooling to room temperature, filter with suction several times and wash with deionized water until pH = 7 to obtain functionalized carbon nanotubes;

[0041] 2) Preparation of functionalized carbon nanotubes: add 100mg functionalized carbon nanotubes to 100mL deionized water, ultrasonically disperse for 1h, add 1mL glacial acetic acid dropwise under 500rpm magnetic stirring, slowly add 0.5g chitosan, and react at 30°C 10h. Then, the obtained product was suction-filtered, washed until neutral, and freeze-dried at -80° C. to obtain functionalized carbon nanotubes.

Embodiment 1

[0043] 1) Preparation of functionalized carbon nanotubes / DMF solution: Take 0.0335g of functionalized carbon nanotubes and add them to 10mL DMF (functionalized carbon nanotubes account for 0.25% of the total mass of TPU raw materials), and stir at 25°C and 500rpm Down stirring 8h standby;

[0044] 2) Add 10g of 4,4'-diphenylmethane diisocyanate into a three-necked flask that has been preheated to 75°C and connected to a vacuum dehydration device, and wait until the 4,4'-diphenylmethane diisocyanate is melted into After the transparent liquid, use a syringe to take the functionalized carbon nanotube / DMF solution obtained in step 1) and add it to the system, and react at 75°C for 1 hour under reduced pressure and mechanical stirring;

[0045] 3) Add 3 g of polytetramethylene ether glycol that has been dehydrated at high temperature to the system described in step 2), keep the conditions of reduced pressure and mechanical stirring, and react at 80°C for 3 hours;

[0046] 4) Add ...

Embodiment 2

[0051] 1) Preparation of functionalized carbon nanotubes / DMF solution: Add 0.0670g functionalized carbon nanotubes to 10mL DMF (functionalized carbon nanotubes account for 0.50% of the total mass of TPU raw materials), and stir at 25°C and 500rpm Down stirring 8h standby;

[0052] 2) Add 10g of 4,4'-diphenylmethane diisocyanate into a three-necked flask that has been preheated to 75°C and connected to a vacuum dehydration device, and wait until the 4,4'-diphenylmethane diisocyanate is melted into After the transparent liquid, use a syringe to take the functionalized carbon nanotube / DMF solution obtained in step 1) and add it to the system, and react at 75°C for 1 hour under reduced pressure and mechanical stirring;

[0053] 3) Add 3 g of polytetramethylene ether glycol that has been dehydrated at high temperature to the system described in step 2), keep the conditions of reduced pressure and mechanical stirring, and react at 80°C for 3 hours;

[0054] 4) Add 15mL DMF to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com