High-elasticity resin modified silicone oil and preparation method thereof

A modified silicon, high-elasticity technology, applied in the direction of improved hand-feeling fibers, fiber types, textiles and papermaking, etc., can solve the problems of quality improvement and inability to achieve, achieve simple process, excellent film-forming properties, and easy reaction process. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

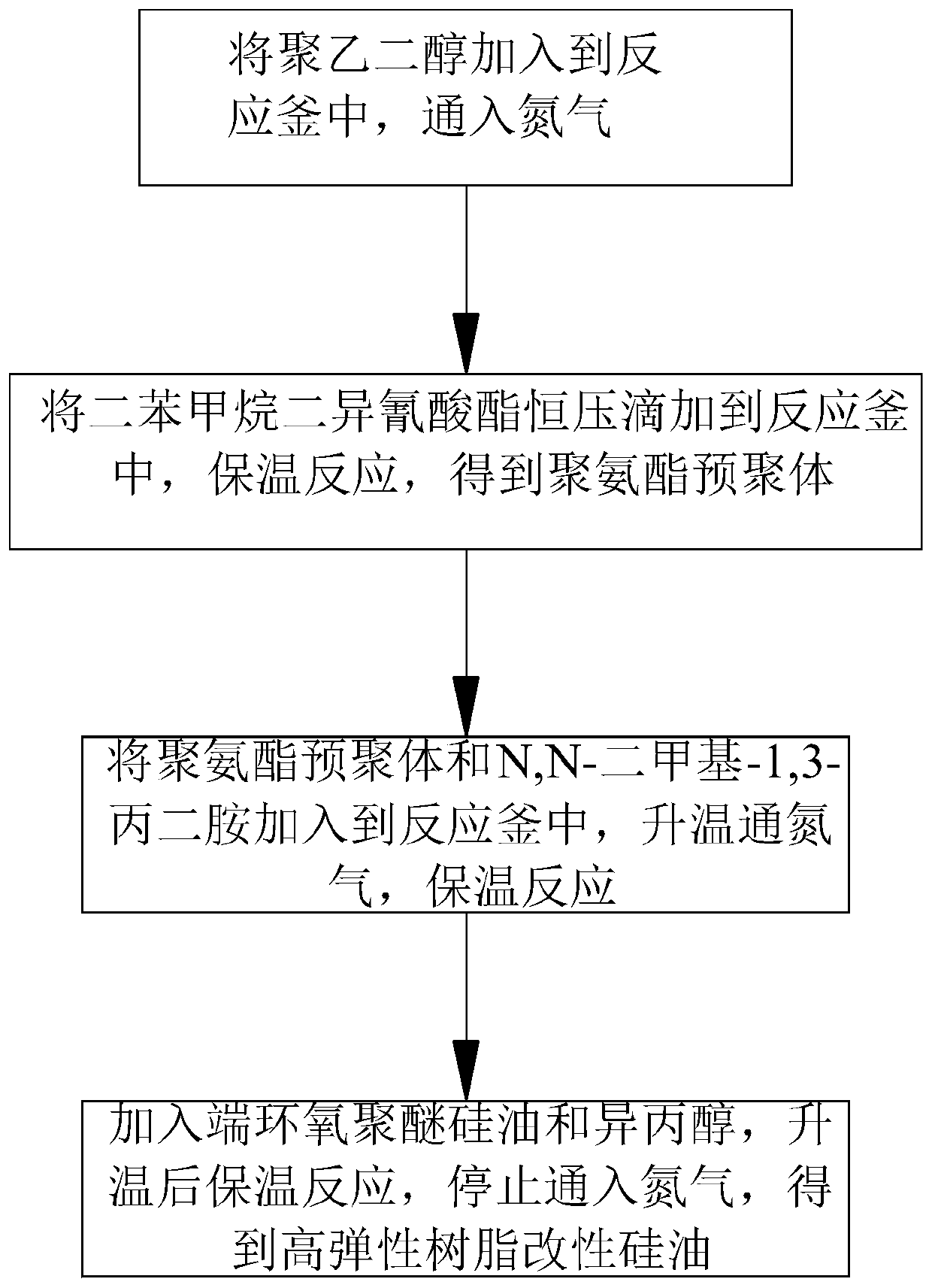

Method used

Image

Examples

Embodiment 1

[0041] (1) Add 30 parts of polyethylene glycol (the number average molecular weight is 150) into a reaction kettle equipped with a thermometer, a stirrer and condensing reflux, raise the temperature to 50 ° C, and feed nitrogen, and 100 parts of diphenylmethane Diisocyanate is slowly added dropwise into the reaction kettle through a constant pressure dropping funnel, and after 3 hours of heat preservation, the temperature is lowered to below 40°C, and nitrogen gas is stopped to obtain a polyurethane prepolymer.

[0042] (2) 200 parts of polyurethane prepolymers obtained and 63 parts of N,N-dimethyl-1,3-propylenediamine are added to the reaction kettle equipped with thermometer, agitator and condensing reflux, and the temperature is raised to 40 ℃, and feed nitrogen, after 4 hours of heat preservation, add 2080 parts of epoxy-terminated polyether silicone oil (number average molecular weight is 9000) and 1300 parts of isopropanol, raise the temperature to 75 ℃, keep the temperat...

Embodiment 2

[0048] (1) Add 45 parts of polyethylene glycol (the number average molecular weight is 200) into a reaction kettle equipped with a thermometer, a stirrer and condensing reflux, raise the temperature to 60 ° C, and feed nitrogen, and 113 parts of diphenylmethane Diisocyanate is slowly added dropwise into the reaction kettle through a constant pressure dropping funnel, and after 2.5 hours of heat preservation, the temperature is lowered to below 40°C, and nitrogen gas is stopped to obtain a polyurethane prepolymer.

[0049] (2) 200 parts of polyurethane prepolymers obtained and 46 parts of N,N-dimethyl-1,3-propylenediamine are added to the reaction kettle equipped with thermometer, agitator and condensing reflux, and the temperature is raised to 45 ℃, and feed nitrogen, after 3 hours of heat preservation, add 2000 parts of epoxy-terminated polyether silicone oil (number average molecular weight: 12000) and 1200 parts of isopropanol, raise the temperature to 80 ℃, keep the tempera...

Embodiment 3

[0051] (1) Add 60 parts of polyethylene glycol (the number average molecular weight is 200) into a reaction kettle equipped with a thermometer, a stirrer and condensing reflux, raise the temperature to 70 ° C, and feed nitrogen, and 150 parts of diphenylmethane Diisocyanate is slowly added dropwise into the reaction kettle through a constant pressure dropping funnel, and after being kept warm for 2 hours, the temperature is lowered to below 40°C, and nitrogen gas is stopped to obtain a polyurethane prepolymer.

[0052](2) Add 200 parts of polyurethane prepolymer and 46 parts of N,N-dimethyl-1,3-propanediamine to the reaction kettle, raise the temperature to 50°C, and feed nitrogen gas for 2 After 1 hour, add 1600 parts of epoxy-terminated polyether silicone oil (the number-average molecular weight is 11000) and 1000 parts of isopropanol, heat up to 80° C., after 10 hours of heat preservation reaction, cool down to below 40° C., stop feeding nitrogen, and obtain High elastic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com