A kind of strong hydrophilic wetting agent for rock surface based on high temperature excitation and preparation method thereof

A technology of water wetting and rock, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as low, even if a part is adsorbed on the rock surface, and the water wettability of the rock surface disappears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

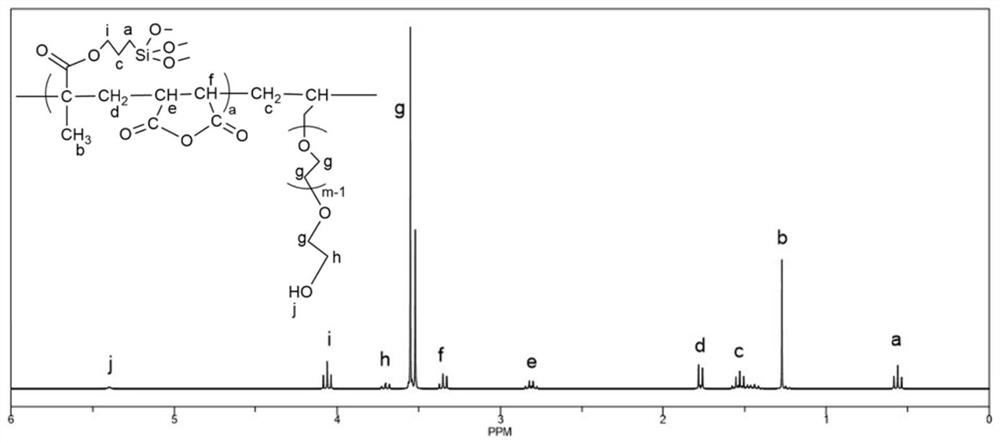

[0032] The strong hydrophilic wetting agent on the rock surface based on high temperature excitation has a structural formula of

[0033]

[0034] Wherein, a is 20-100 times of b, m=5-100, n=200-300.

[0035] The preparation method of the rock surface strong hydrophilic wetting agent based on high-temperature excitation is specifically as follows: first, 98g (1mol) maleic anhydride, 10.47g initiator azobisisobutyronitrile (AIBN) and 98g dimethyl formaldehyde Amide (DMF) was added to the flask, heated to 70°C with constant stirring, and then 3g (0.01mol) of low molecular weight allyl polyether with a molecular weight of 300 was added; A mixed solution composed of acyloxypropyltrimethoxysilane and 248g DMF was incubated at 75°C for 5 hours, and the solvent DMF was distilled off under reduced pressure to obtain a yellow solid, which was pulverized to obtain a strongly hydrophilic rock surface based on high temperature excitation. D.

Embodiment 2

[0037] The preparation method of the rock surface strong hydrophilic wetting agent based on high-temperature excitation is specifically as follows: first, 98g (1mol) maleic anhydride, 10.65g initiator azobisisobutyronitrile (AIBN) and 98g dimethyl formaldehyde Amide (DMF) was added to the flask, heated to 70°C with constant stirring, and then 6g (0.02mol) of low molecular weight allyl polyether with a molecular weight of 300 was added; A mixed solution composed of acyloxypropyltrimethoxysilane and 248g DMF was incubated at 75°C for 5 hours, and the solvent DMF was distilled off under reduced pressure to obtain a yellow solid, which was pulverized to obtain a strongly hydrophilic rock surface based on high temperature excitation. D.

Embodiment 3

[0039] The preparation method of the rock surface strong hydrophilic wetting agent based on high-temperature excitation is specifically as follows: first, 98g (1mol) maleic anhydride, 10.65g initiator azobisisobutyronitrile (AIBN) and 98g dimethyl formaldehyde Amide (DMF) was added to the flask, heated to 70°C with constant stirring, and then 9g (0.03mol) of low molecular weight allyl polyether with a molecular weight of 300 was added; A mixed solution composed of acyloxypropyltrimethoxysilane and 248g DMF was incubated at 75°C for 5 hours, and the solvent DMF was distilled off under reduced pressure to obtain a yellow solid, which was pulverized to obtain a strongly hydrophilic rock surface based on high temperature excitation. D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com