Manufacturing methodof rhenium disulfide supercapacitor based on biological template method growth

A technology of supercapacitor and manufacturing method, which is applied in chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problem that rhenium disulfide is prone to stacking and agglomeration, and rhenium disulfide cannot be widely used in supercapacitors. Active materials, low crystallinity, etc., achieve the effects of green production practice, easy production practice, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

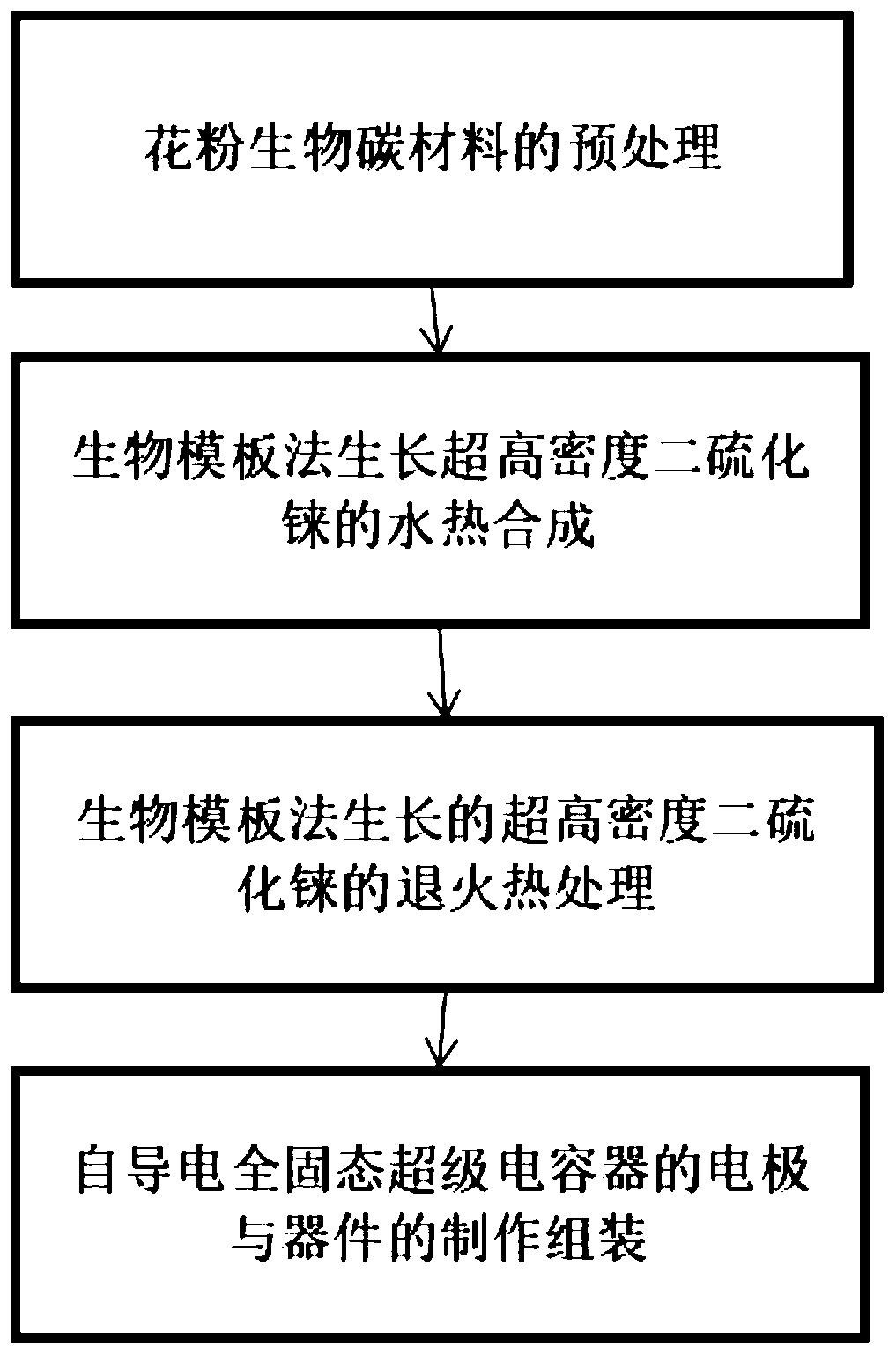

[0036] Step 1: Carbonization is a typical method for constructing biological templates. However, severe heat treatment easily deteriorates the pollen structure, leading to morphological collapse and pore size reduction. Therefore, pre-carbonization treatment is necessary to strengthen the structure. In Example 1 of the present invention, 10 g of crude rape pollen grains (Kanghuang Bee Industry Co., Ltd.) were immersed in ethanol (analytical grade, Chengdu Cologne reagent) for 1 h ultrasonic treatment (75W, 40KHz), and then rinsed with deionized water 3 times. Subsequently, the treated crude rape pollen grains were added to 150 mL mixed solution (V ethanol: V formaldehyde = 1: 1) (analytical grade, Chengdu Cologne reagent) under stirring for 10 minutes, then washed and filtered through deionized water for 3 Second-rate. Afterwards, crude rape pollen grains were transferred into 100 mL of 12 M sulfuric acid and vigorously stirred in a water bath at 80 °C for 4 h. After filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com