Wear-resistant antiskid polyurethane solid tire and preparation method thereof

A polyurethane and polyurethane layer technology, applied in special tires, non-pneumatic tires, vehicle parts, etc., can solve problems such as the loose combination of the rim and the polyurethane layer, increase the surface roughness of the metal rim, and the rigidity of the polyurethane molecular chain, so as to improve the anti-skid effect, good wear resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

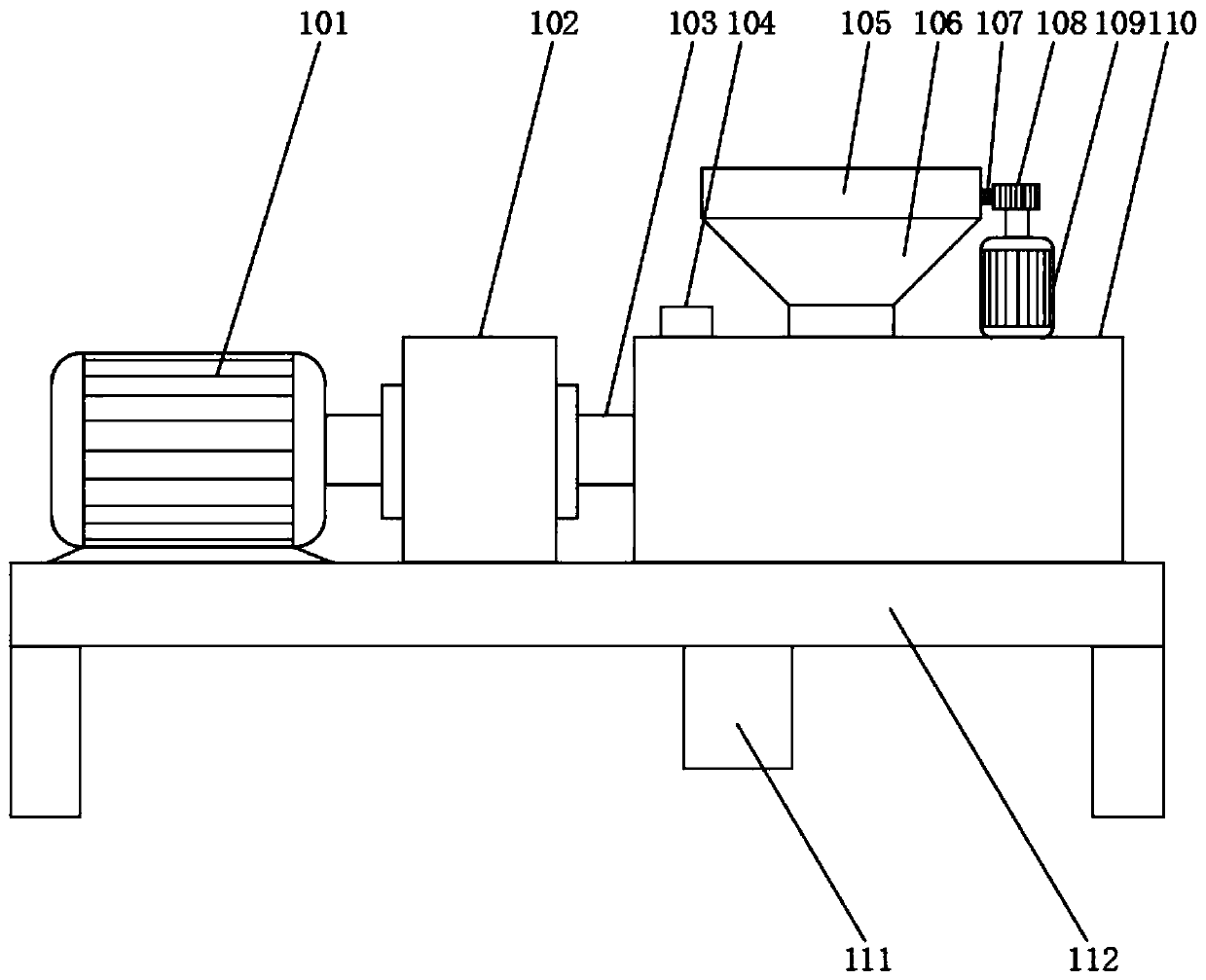

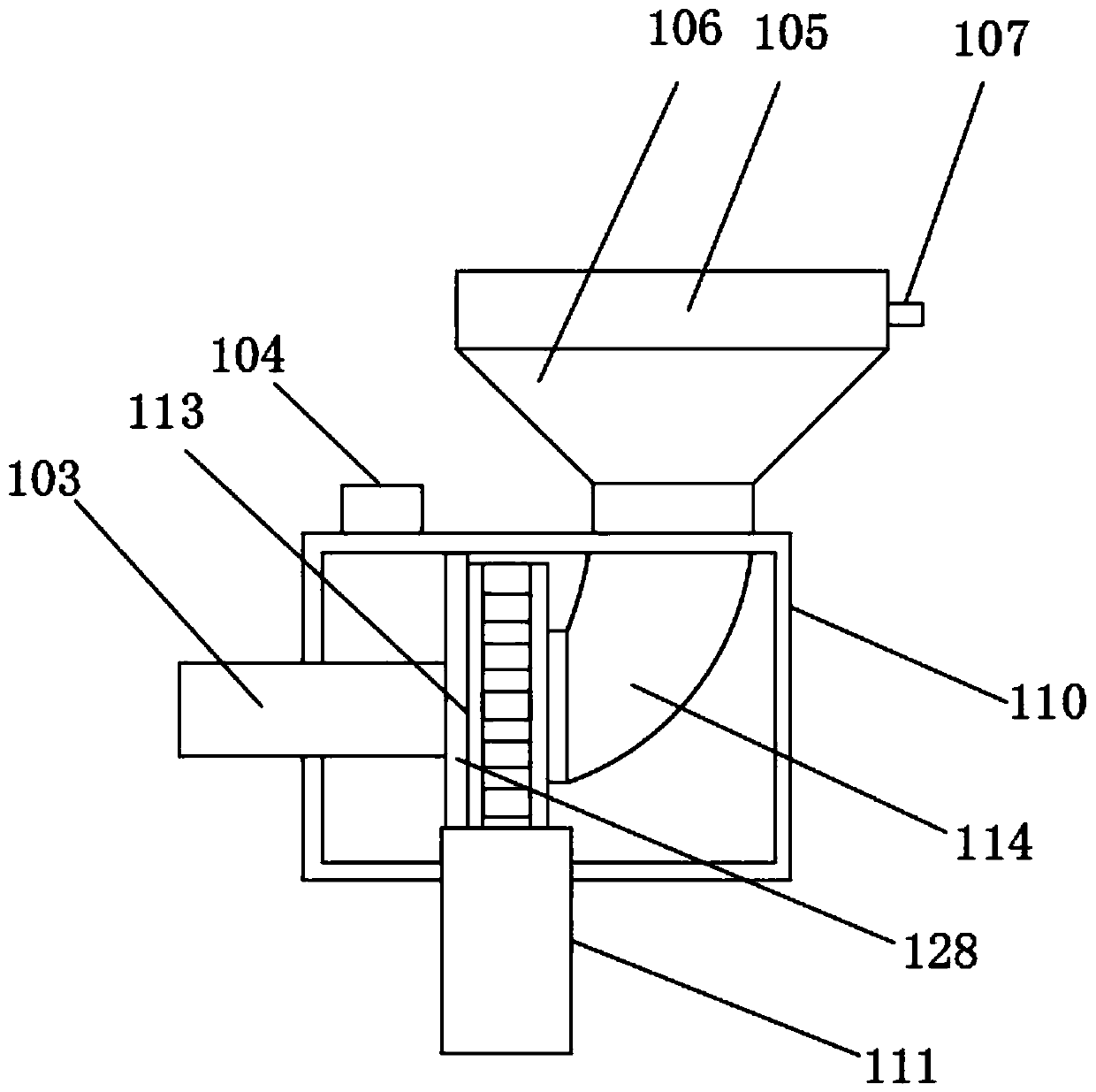

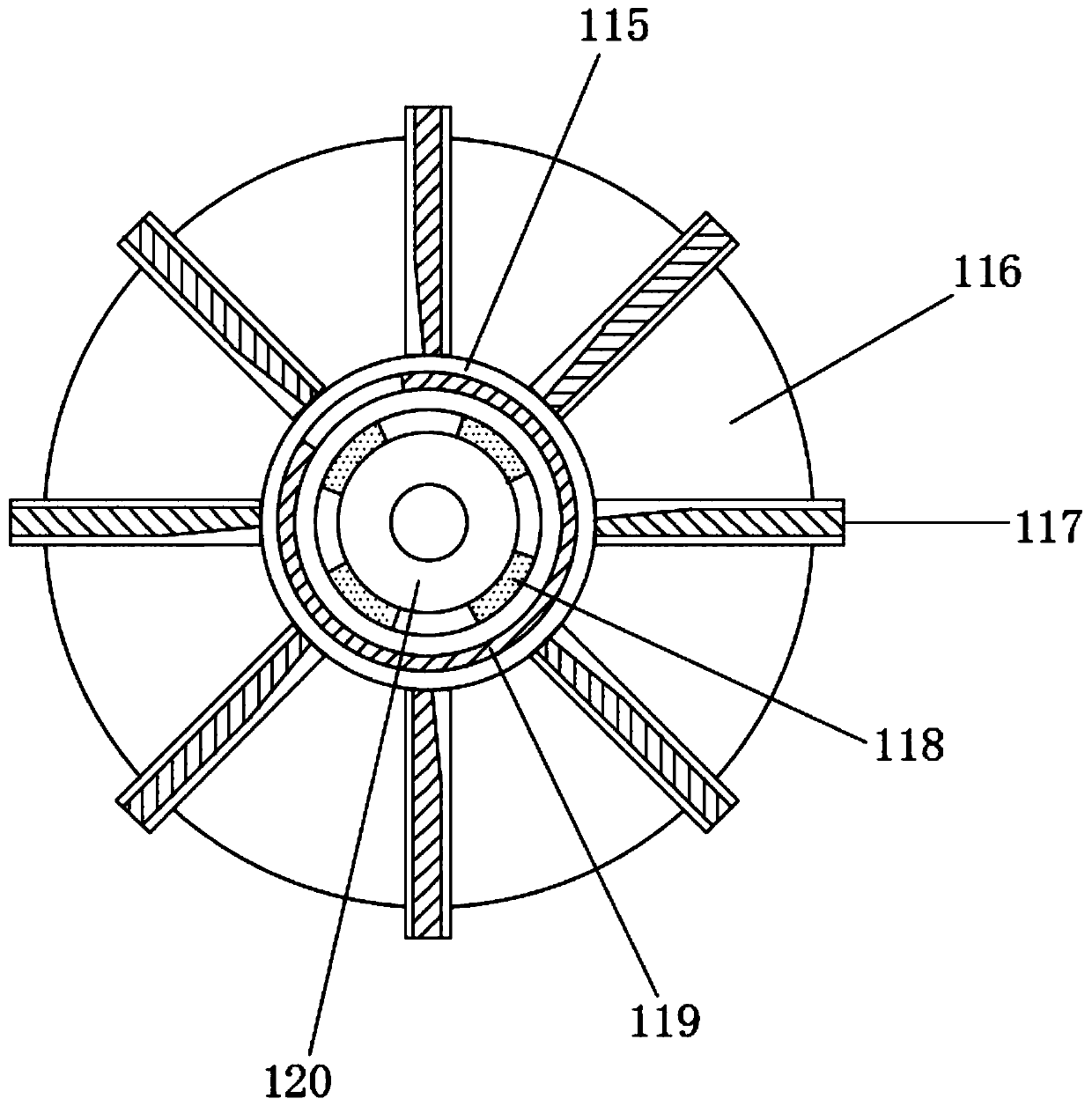

[0049] see Figure 1-5 As shown, the present embodiment is a wear-resistant and non-slip polyurethane solid tire, comprising a metal rim and a polyurethane layer adhered to the outer surface of the metal rim;

[0050] The polyurethane layer is prepared from the following components in parts by weight:

[0051] 90 parts of polyether diol, 20 parts of isophorone diisocyanate, 1 part of catalyst, 10 parts of chain extender, 5 parts of flame retardant, 0.5 part of antioxidant;

[0052] The wear-resistant and non-slip polyurethane solid tire is prepared by the following steps:

[0053] Step 1: Surface treatment of the metal rim;

[0054] Step 2: preparing polyurethane prepolymer;

[0055] Step 3: Prepare a wear-resistant and anti-skid polyurethane solid tire.

[0056] The material of the metal rim is one of cast iron, stainless steel and aluminum alloy; the thickness of the polyurethane layer is 30-60mm.

[0057] The catalyst is a mixture of one or more of triethylenediamine, ...

Embodiment 2

[0076] see Figure 1-5 As shown, the present embodiment is a wear-resistant and non-slip polyurethane solid tire, comprising a metal rim and a polyurethane layer adhered to the outer surface of the metal rim;

[0077] The polyurethane layer is prepared from the following components in parts by weight:

[0078] 100 parts of polyether diol, 30 parts of isophorone diisocyanate, 2 parts of catalyst, 15 parts of chain extender, 8 parts of flame retardant, 0.7 part of antioxidant;

[0079] The wear-resistant and non-slip polyurethane solid tire is prepared by the following steps:

[0080] Step 1: Surface treatment of the metal rim;

[0081] Step 2: preparing polyurethane prepolymer;

[0082] Step 3: Prepare a wear-resistant and anti-skid polyurethane solid tire.

[0083] The material of the metal rim is one of cast iron, stainless steel and aluminum alloy; the thickness of the polyurethane layer is 30-60mm.

[0084] The catalyst is a mixture of one or more of triethylenediamine...

Embodiment 3

[0103] see Figure 1-5 As shown, the present embodiment is a wear-resistant and non-slip polyurethane solid tire, comprising a metal rim and a polyurethane layer adhered to the outer surface of the metal rim;

[0104] The polyurethane layer is prepared from the following components in parts by weight:

[0105] 110 parts of polyether diol, 40 parts of isophorone diisocyanate, 3 parts of catalyst, 20 parts of chain extender, 10 parts of flame retardant, 1 part of antioxidant;

[0106] The wear-resistant and non-slip polyurethane solid tire is prepared by the following steps:

[0107] Step 1: Surface treatment of the metal rim;

[0108] Step 2: preparing polyurethane prepolymer;

[0109] Step 3: Prepare a wear-resistant and anti-skid polyurethane solid tire.

[0110] The material of the metal rim is one of cast iron, stainless steel and aluminum alloy; the thickness of the polyurethane layer is 30-60mm.

[0111] The catalyst is a mixture of one or more of triethylenediamine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com