A naturally degradable vacuum-sealed plastic bag

A technology of vacuum sealing and plastic bags, which is applied to bags, sacks, climate sustainability, etc., can solve the problems of large impact on the surrounding environment, poor effect of plastic bags, and secondary pollution of the environment, achieving high safety and degradability Good performance, promote the effect of oxidative degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

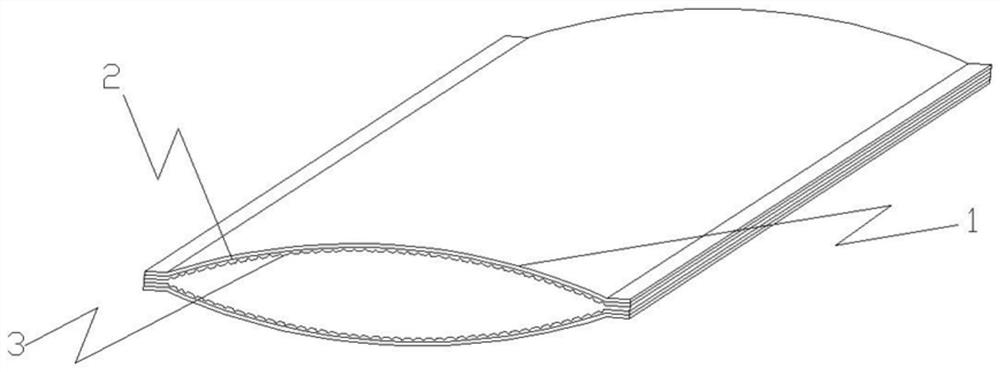

[0026] Such as Figure 1 As shown, the present invention provides a naturally degradable vacuum-sealed plastic bag, the vacuum-sealed plastic bag includes a bag body, the bag body is composed of several layers of film layers and is placed in the middle of the bag body A storage cavity is formed, and the storage cavity is used to accommodate food, and at least one layer of the film layers of the several layers uses a degradation-promoting material, wherein the film layer materials for the preparation of the several layers contain polyethylene, according to the mass percentage , the added amount of the degradation-promoting material is 5% of the polyethylene. And the film layers of the several layers are compounded by laminating the prepared inner film layer and outer film layer or the inner film layer, middle layer film layer and outer film layer sequentially, and obtaining the obtained film by roller hot pressing and shaping. The vacuum-sealed plastic bag includes a bag body....

Embodiment 2

[0031] Such as Figure 1 As shown, the present invention provides a naturally degradable vacuum-sealed plastic bag, the vacuum-sealed plastic bag includes a bag body, the bag body is composed of several layers of film layers and is placed in the middle of the bag body A storage cavity is formed, and the storage cavity is used to accommodate food, and at least one layer of the film layers of the several layers uses a degradation-promoting material, wherein the film layer materials for the preparation of the several layers contain polyethylene, according to the mass percentage , the added amount of the degradation-promoting material is 5% of the polyethylene. And the film layers of the several layers are compounded by laminating the prepared inner film layer and outer film layer or the inner film layer, middle layer film layer and outer film layer sequentially, and obtaining the obtained film by roller hot pressing and shaping. The vacuum-sealed plastic bag includes a bag body....

Embodiment 3

[0036] Such as Figure 1 As shown, the present invention provides a naturally degradable vacuum-sealed plastic bag, the vacuum-sealed plastic bag includes a bag body, the bag body is composed of several layers of film layers and is placed in the middle of the bag body A storage cavity is formed, and the storage cavity is used to accommodate food, and at least one layer of the film layers of the several layers uses a degradation-promoting material, wherein the film layer materials for the preparation of the several layers contain polyethylene, according to the mass percentage , the added amount of the degradation-promoting material is 5% of the polyethylene. And the film layers of the several layers are compounded by laminating the prepared inner film layer and outer film layer or the inner film layer, middle layer film layer and outer film layer sequentially, and obtaining the obtained film by roller hot pressing and shaping. The vacuum-sealed plastic bag includes a bag body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com