A preparation method for intermediate transition layer applied in vacuum diffusion welding

A technology of vacuum diffusion and transition layer, applied in welding equipment, vacuum evaporation coating, coating, etc., can solve the problems of poor welding quality of structural parts, difficulty in achieving close and uniform fit of nickel foil and welding surface, low purity, etc. , to achieve the effect of improving welding quality, easy to fit tightly and evenly, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1. A method for preparing an intermediate transition layer applied to vacuum diffusion welding. A nickel film is prepared on the welding surface of a part (made of tin bronze, material grade QSn6.5-0.1), comprising the following steps,

[0034] Preliminary preparation work, prepare the nickel target, the purity of the nickel target is 99.99%, and the thickness is 4mm, put the nickel target into the sputtering chamber of the magnetron sputtering coating equipment, connect the nickel target to the DC power supply in the sputtering chamber, adjust The distance between the nickel target and the workpiece holder is between 100-180mm.

[0035] a. Soak the parts in gasoline for 20, 25 or 30 minutes, preferably 25 minutes, to obtain product A;

[0036] b. Wash product A with tap water for 1, 2 or 3 minutes, preferably 2 minutes, to obtain product B;

[0037] c. Use 15%, 18% or 20% concentration of HNO 3 Pickling product B with solution for 1, 1.5 or 2 minutes, the op...

Embodiment 2

[0048] Example 2. A method for preparing an intermediate transition layer applied to vacuum diffusion welding. Compared with Example 1, the only difference is that the material of the part is tin bronze, the brand name is ZQSn10-2-3.

Embodiment 3

[0049] Example 3. A method for preparing an intermediate transition layer applied to vacuum diffusion welding. Compared with Example 1, the only difference is that the material of the part is alloy steel, brand 40CrNiMoA.

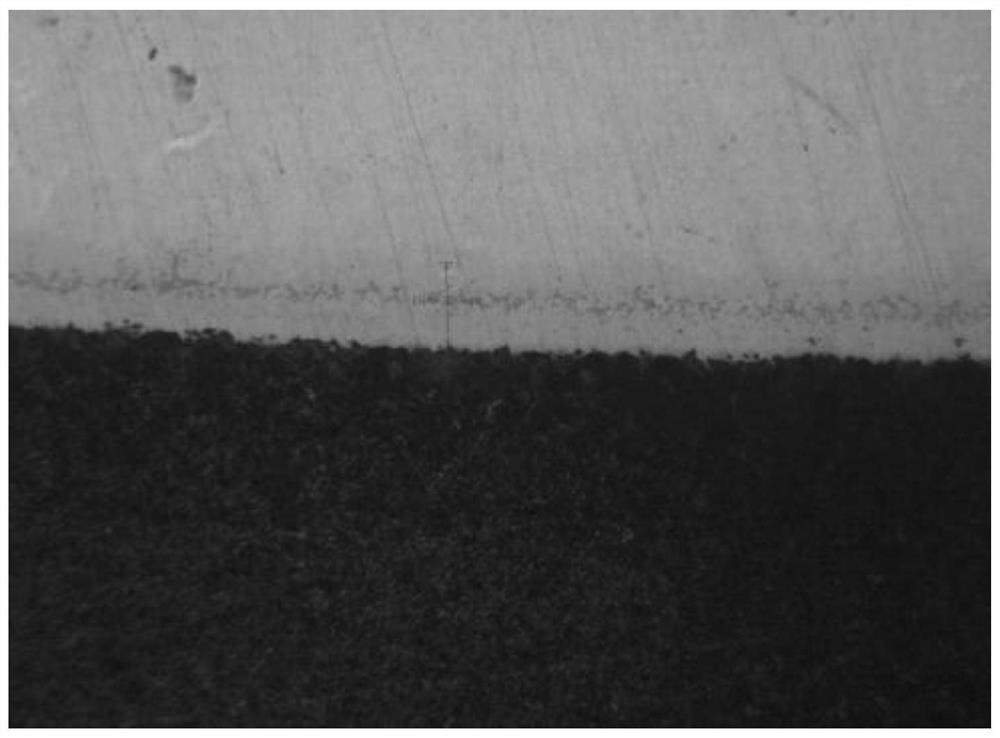

[0050] The finished product gained in embodiment 1 and the finished product gained in embodiment 3 are carried out vacuum diffusion welding, from figure 1 It can be seen that the intermediate transition layer (that is, the coating or nickel layer) has a very good diffusion connection effect. After measurement, the thickness of the transition layer (the transition layer is composed of the intermediate transition layer plated on the two finished products) reaches 20um. The thickness is uniform, the tensile strength between the two finished products is ≥320 MPa, and the welding quality is good.

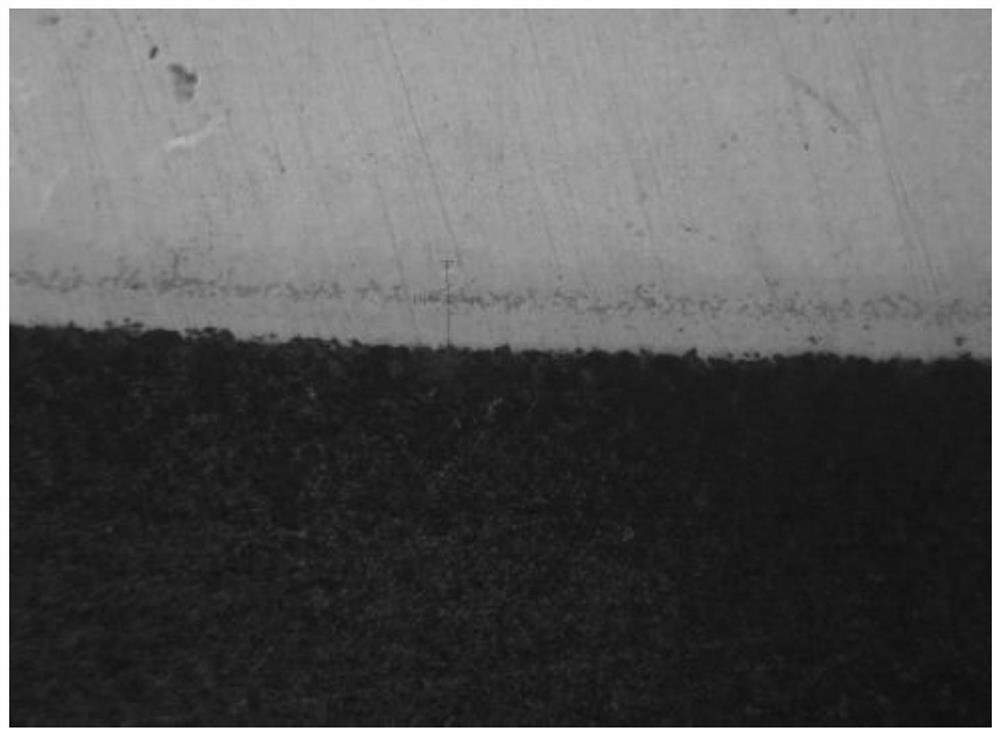

[0051] The finished product gained in embodiment 2 and the finished product gained in embodiment 3 are carried out vacuum diffusion welding, from figure 2 It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com